Understanding the Mechanism Behind Variable Frequency Motors

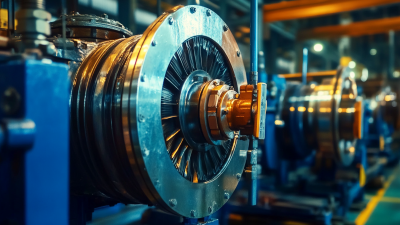

Variable Frequency Motors (VFMs) play a crucial role in modern industrial applications, driving efficiency and performance across a range of sectors. According to the International Energy Agency, electric motors account for about 45% of global electricity consumption within the industrial sector, with a significant proportion of these using variable frequency drives (VFDs) to optimize energy usage. The ability of VFMs to adjust their speed and torque, based on demand, not only enhances operational efficiency but also reduces wear and tear on equipment, leading to lower maintenance costs. As industries increasingly focus on sustainability and cost-efficiency, understanding the mechanisms behind Variable Frequency Motors is essential. This blog aims to provide a comprehensive checklist that highlights the key components, advantages, and operational insights of VFMs, ensuring that professionals can leverage this technology to its fullest potential.

Variable Frequency Motors (VFMs) play a crucial role in modern industrial applications, driving efficiency and performance across a range of sectors. According to the International Energy Agency, electric motors account for about 45% of global electricity consumption within the industrial sector, with a significant proportion of these using variable frequency drives (VFDs) to optimize energy usage. The ability of VFMs to adjust their speed and torque, based on demand, not only enhances operational efficiency but also reduces wear and tear on equipment, leading to lower maintenance costs. As industries increasingly focus on sustainability and cost-efficiency, understanding the mechanisms behind Variable Frequency Motors is essential. This blog aims to provide a comprehensive checklist that highlights the key components, advantages, and operational insights of VFMs, ensuring that professionals can leverage this technology to its fullest potential.

The Basics of Variable Frequency Motors and Their Functionality

Variable Frequency Motors (VFMs) are integral components in modern industrial automation, enabling precise control over motor speed and torque. By adjusting the frequency and voltage supplied to the motor, VFMs can optimize performance across various applications, from pumps and fans to conveyors. A recent report by Allied Market Research indicates that the global market for variable frequency drives, a key technology behind VFMs, is expected to reach $27.78 billion by 2027, growing at a compound annual growth rate (CAGR) of 6.5%. This surge is largely driven by the increasing demand for energy-efficient solutions in manufacturing and process industries.

Understanding the basic functionality of VFMs involves recognizing their ability to convert power from a fixed frequency supply (like standard grid power) to a variable frequency output. This function not only enhances operational efficiency but also reduces energy consumption. According to a study from the U.S. Department of Energy, implementing VFMs can lead to energy savings of 20-50% in certain applications, thus significantly lowering operational costs. Moreover, the flexibility that VFMs allow in controlling motor speed aids in maintaining optimal performance, ultimately leading to greater production efficiencies and reduced wear on mechanical components.

Key Benefits of Using Variable Frequency Motors in Industrial Applications

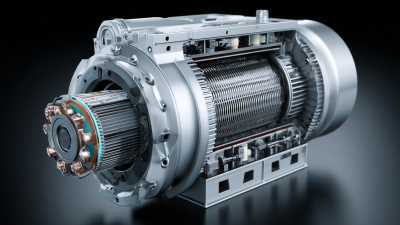

Variable Frequency Motors (VFMs) have become integral to modern industrial applications due to their significant benefits in energy efficiency and operational flexibility. According to a recent report by the International Energy Agency (IEA), VFMs can reduce energy consumption by up to 50% compared to traditional motor systems, which is vital in an environment where manufacturers are increasingly pressured to minimize operational costs. This ability to vary the motor speed allows industries to optimize their processes, leading to substantial savings and decreased energy waste.

Additionally, VFMs provide enhanced control over motor performance, which is particularly beneficial for applications that demand precise speed regulation, such as conveyor systems and pumps. A study from the U.S. Department of Energy indicates that implementing VFMs in these applications can improve production efficiency by as much as 30%. Furthermore, with their dynamic response capabilities, Variable Frequency Motors facilitate smoother operations, reducing mechanical stress and prolonging equipment lifespan, ultimately contributing to lower maintenance costs. The increasing adoption of VFMs across sectors like manufacturing, oil and gas, and HVAC is a testament to their transformative impact on industrial motor applications.

Understanding the Key Benefits of Using Variable Frequency Motors in Industrial Applications

How Variable Frequency Drives Enhance Energy Efficiency

Variable frequency drives (VFDs) play a crucial role in enhancing energy efficiency, particularly in applications involving pumps and fans. By allowing for precise control of speed and energy consumption, VFDs can significantly lower operational costs, making them an essential component for energy-intensive industries. For instance, optimizing the motor efficiency through VFDs can lead to considerable energy savings, as they adjust the motor speed to match the actual demand, which minimizes wasted energy.

Tips for Enhancing Energy Efficiency with VFDs:

- Regular Maintenance: Ensure that your VFD systems are regularly maintained and calibrated to operate efficiently. Periodic checks can detect issues before they escalate, preserving both energy and equipment lifespan.

- Choose the Right VFD Size: Selecting a VFD that precisely matches the motor's requirements can improve performance. Oversized drives can lead to inefficiencies, while undersized drives may not adequately meet the demand, both resulting in unnecessary energy usage.

- Integrate Monitoring Systems: Implement energy monitoring tools to track energy consumption. This data can provide insights into usage patterns and identify opportunities for further optimization, leading to sustainable energy management practices.

Incorporating these strategies can not only enhance the efficiency of drive systems but also contribute to a greener operational profile for industries reliant on variable frequency motors.

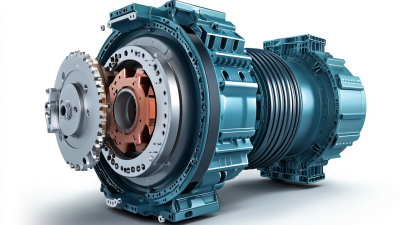

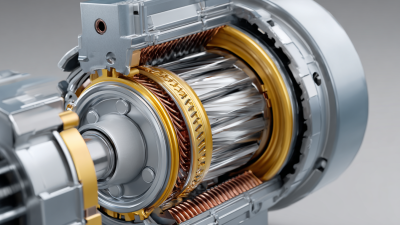

Understanding the Control Mechanisms of Variable Frequency Motors

Variable Frequency Drives (VFDs) play a crucial role in controlling the speed and torque of variable frequency motors (VFMs), making them essential in modern industrial applications. One of the key mechanisms behind VFDs involves pulse-width modulation (PWM). This method allows for the precise adjustment of output voltage and frequency, enabling VFMs to operate at various speeds while ensuring energy efficiency. According to a recent industry report from ResearchAndMarkets, the global VFD market is projected to grow at a compound annual growth rate (CAGR) of 7.2% from 2022 to 2027, indicating a strong trend towards the adoption of these control mechanisms in various sectors.

In addition to PWM, advanced control strategies like sensorless vector control and direct torque control further enhance the performance of VFMs. These techniques improve dynamic response and torque production, ensuring that motors can handle varying load conditions effectively. A study by the International Energy Agency (IEA) pointed out that optimizing motor control can lead to energy savings of up to 30% in motor-driven systems. As industries increasingly focus on sustainability and energy efficiency, understanding the control mechanisms of Variable Frequency Motors becomes vital to leveraging their full potential and contributing to greener industrial practices.

Common Applications and Real-World Impact of Variable Frequency Motors

Variable frequency motors (VFMs) are increasingly pivotal in various industrial applications, particularly in pumping systems where efficiency and adaptability are paramount. A recent industry report highlighted that the implementation of variable frequency drives (VFDs) has surged, with these systems accounting for nearly 60% of all industrial motor applications. This trend can be attributed to their ability to adjust motor speed and torque to match the demands of the pumping process, resulting in significant energy savings and reduced operational costs.

In practical terms, the use of VFDs in pumping systems enables operators to maintain optimal flow rates and pressure without the need for costly mechanical adjustments. For instance, research indicates that optimizing the speed of pumps through VFDs can lead to energy savings of up to 30% compared to traditional fixed-speed systems. Furthermore, industries such as water treatment and HVAC have increasingly adopted VFD technology, illustrating its versatility and the positive environmental impact through reduced carbon emissions. The ability to fine-tune operations not only enhances efficiency but also contributes to sustainable practices across various sectors.

Understanding the Mechanism Behind Variable Frequency Motors - Common Applications and Real-World Impact of Variable Frequency Motors

| Application | Industry | Energy Savings (%) | Control Type | Common Motor Type |

|---|---|---|---|---|

| HVAC Systems | Construction | 30-50 | Vector Control | Induction Motor |

| Pumps | Water Management | 20-40 | Sensorless Vector Control | Synchronous Motor |

| Conveyor Systems | Manufacturing | 15-25 | Torque Control | Permanent Magnet Motor |

| Elevators | Transportation | 20-35 | Closed-loop Control | Gearless Motor |

| Washing Machines | Appliances | 15-30 | Direct Control | Brushless DC Motor |

Related Posts

-

5 Reasons Why the Best Three Phase AC Motor is Essential for Your Industry Needs

-

5 Powerful Reasons to Choose the Best Three Phase AC Motor for Your Business

-

Rising Above Tariff Challenges: How China's Best Electric Motor Manufacturers Thrive

-

10 Reasons Why the Best AC Motors Outperform Competitors in Efficiency and Longevity

-

Top Strategies for Sourcing the Best Low Speed Motor Innovatively and Cost Effectively

-

Quality Induction Motors Made in China Setting New Standards for Global Procurement

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top