Understanding the Magic Behind Electrical Fan Motors: How They Keep You Cool

The Electrical Fan Motor plays an essential role in providing comfort and cooling in both residential and commercial settings. According to the U.S. Department of Energy, fans can be an energy-efficient alternative to air conditioning, using up to 90% less energy than traditional cooling systems. In fact, the global market for electric fans is projected to reach $7.1 billion by 2026, highlighting an increasing reliance on electrical fan motors for addressing heat and humidity.

Understanding how these motors work not only helps in selecting the right fan but also empowers users to optimize their performance and extend their lifespan. By delving into the intricate workings of electrical fan motors, we can unlock the secrets behind their efficiency and reliability, making strides towards a more comfortable living environment while being mindful of energy consumption.

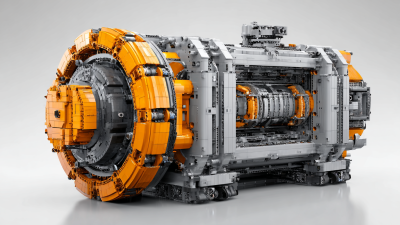

The Anatomy of Electrical Fan Motors: Key Components Explained

Electrical fan motors consist of several key components that work together to create the cooling breeze we often rely on during hot weather. The heart of the motor is the stator, which is the stationary part that houses coils of wire. When electric current flows through these coils, it generates a magnetic field. This interaction with the rotor, which is the rotating part of the motor, leads to motion. The rotor itself is typically attached to the fan blades, which are designed to move air efficiently when rotated.

Another crucial component is the capacitor, which stores electrical energy and helps start the motor. Capacitors can enhance the efficiency of the motor by providing an extra boost of power during startup, allowing for a smoother operation. Additionally, bearings facilitate the smooth rotation of the rotor, reducing friction and wear. Lastly, the housing encases these components, providing protection and minimizing noise. Together, these elements orchestrate the cooling effect fans distribute, making them essential in both residential and commercial settings.

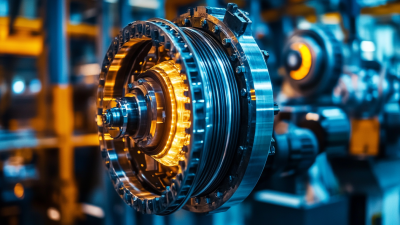

How Electrical Fan Motors Convert Electricity into Motion

Electrical fan motors are an essential component in maintaining comfort in indoor environments, as they convert electrical energy into mechanical motion. These motors typically operate on the principles of electromagnetism. When current flows through the winding coils of the motor, it generates magnetic fields that interact with the permanent magnets or the rotor, causing the motor to spin. According to a report by the International Energy Agency (IEA), fans account for approximately 20% of global electricity consumption in commercial buildings, highlighting the significance of efficient motor designs.

The efficiency of electrical fan motors has been a focal point for industry advancements, with most modern designs achieving efficiencies upwards of 80%. As outlined in the 2021 U.S. Department of Energy (DOE) efficiency standards, enhanced fan blade design and motor technology have enabled significant energy savings. For instance, brushless DC motors are becoming increasingly popular due to their higher efficiency rates and lower operational costs. Consequently, adopting these advanced motor technologies not only helps in reducing electricity usage but also contributes to a more sustainable environment. The evolution of electrical fan motors exemplifies a blend of innovation and practicality, ensuring effective cooling solutions for a wide range of applications.

Understanding Different Types of Electric Motors Used in Fans

Electric fans rely on various types of electric motors to provide effective cooling solutions in our daily lives. Understanding these motors is crucial, as they are the heart of the fan’s operation. The common motor types include AC and DC motors, each offering different efficiencies and power outputs. AC motors are often used in larger fans, providing robust performance for cooling spaces like living rooms and offices, while DC motors are more commonly found in portable units due to their energy efficiency and quieter operation.

In addition to traditional fans, specialized motors play a key role in other applications, such as furnace inducer motors. These motors are vital for ensuring proper air circulation for combustion and venting exhaust gases effectively. As the market shifts towards energy-efficient technologies, advancements in motor designs and airflow analysis are becoming increasingly important. This focus not only enhances cooling efficiency but also contributes significantly to energy savings, highlighting the importance of selecting the right fan motor for both comfort and sustainability.

Understanding the Different Types of Electric Motors Used in Fans

The Role of Bearings and Blades in Maximizing Fan Efficiency

Electric fan motors are marvels of engineering, and their efficiency heavily depends on the design and functionality of bearings and blades. High-quality bearings reduce friction, allowing the fan to operate smoothly and quietly. According to an industry report by the Electrical and Electronics Engineers Society, fans equipped with superior bearings can achieve efficiency ratings up to 90%, greatly extending their lifespan and minimizing energy consumption. This highlights the importance of selecting a fan with premium bearings to ensure long-term performance.

The blades of a fan also play a critical role in enhancing airflow and cooling ability. The shape, pitch, and material of the blades influence how much air is moved. Research published in the Journal of Mechanical Engineering indicates that fans with aerodynamically designed blades can improve airflow by up to 30%, leading to more effective cooling. Choosing the right blade design is essential for maximizing performance, particularly in larger spaces.

Tips: When selecting an electric fan, prioritize models with high-efficiency bearings and well-designed blades. Regular maintenance, such as cleaning the blades and ensuring the bearings are lubricated, can enhance the fan's performance and longevity. Furthermore, consider the fan's placement; positioning it strategically can optimize airflow throughout the room.

Troubleshooting Common Issues in Electrical Fan Motors

Electrical fan motors play a crucial role in keeping indoor spaces comfortable, but they can occasionally encounter issues that affect performance. One common problem is overheating, often caused by a dirty motor or lack of lubrication. According to a report by the National Institute of Standards and Technology (NIST), approximately 12% of all electric motor failures are attributed to inadequate maintenance. Ensuring that the fan motor is cleaned regularly and lubricated can significantly extend its lifespan and reliability.

Electrical fan motors play a crucial role in keeping indoor spaces comfortable, but they can occasionally encounter issues that affect performance. One common problem is overheating, often caused by a dirty motor or lack of lubrication. According to a report by the National Institute of Standards and Technology (NIST), approximately 12% of all electric motor failures are attributed to inadequate maintenance. Ensuring that the fan motor is cleaned regularly and lubricated can significantly extend its lifespan and reliability.

Another prevalent issue is noise during operation, which can indicate mechanical wear or bearing failure. A study by the Electric Power Research Institute suggests that unexpected noise in electric motors may be a symptom of deeper technical problems, and addressing these issues promptly can prevent further damage. Ensuring proper alignment and inspecting for loose components are vital steps in troubleshooting noise-related concerns. In fact, addressing these issues early can lead to a reduction in operational costs by up to 30%, according to the Department of Energy. Regular maintenance and timely troubleshooting can keep electrical fan motors running smoothly, ensuring that you stay cool when you need it most.

Related Posts

-

Crafting Excellence with Chinese Manufacturing Bringing the Best Mining Motor to the Global Market

-

Unmatched Excellence in Chinese Manufacturing Leading the Global RV Gearbox Export Market

-

Exploring Rv Gearbox Innovations at the 138th Canton Fair 2025: Industry Trends and Insights

-

Rising Above Tariffs: How China's Best Induction Motors Thrive in a Competitive Market

-

What is an Aluminum Motor and Why is it Essential for Modern Machinery

-

How to Choose the Right Frequency Converter for Your Industrial Needs

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top