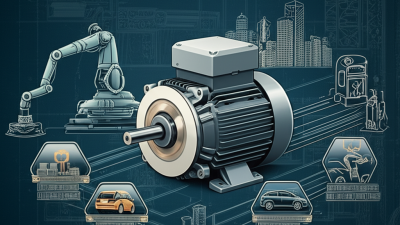

Understanding AC Motors: How They Power Modern Technology and Industry

In the realm of modern technology and industrial applications, the significance of AC motors cannot be overstated. These versatile machines transform electrical energy into mechanical power, driving a vast array of devices and systems that form the backbone of our daily lives.

From powering household appliances like refrigerators and air conditioners to facilitating complex operations in manufacturing plants, AC motors are essential for efficiency and performance. Understanding the various types of AC motors, including synchronous and induction motors, is crucial for optimizing their use and maintenance.

This exploration not only highlights the operational principles of these motors but also sheds light on their pivotal role in advancing technological innovations, enhancing productivity, and promoting sustainability in various sectors.

Through this discussion, we aim to provide a comprehensive overview of how AC motors operate and their influence on the evolution of modern industry.

From powering household appliances like refrigerators and air conditioners to facilitating complex operations in manufacturing plants, AC motors are essential for efficiency and performance. Understanding the various types of AC motors, including synchronous and induction motors, is crucial for optimizing their use and maintenance.

This exploration not only highlights the operational principles of these motors but also sheds light on their pivotal role in advancing technological innovations, enhancing productivity, and promoting sustainability in various sectors.

Through this discussion, we aim to provide a comprehensive overview of how AC motors operate and their influence on the evolution of modern industry.

Key Components of AC Motors: What You Need to Know

AC motors are essential components in modern technology and industry, widely utilized due to their efficiency and reliability. Key components of AC motors include the stator, rotor, and a power supply. The stator is the stationary part of the motor that generates a rotating magnetic field when alternating current (AC) flows through its windings. According to a report by Allied Market Research, the global AC motor market is projected to reach $156.74 billion by 2027, highlighting its crucial role in industrial applications and automation.

The rotor, which can be of various designs such as squirrel-cage or wound types, responds to the magnetic field produced by the stator, leading to motion. The efficiency of AC motors is significantly enhanced by advancements in materials and design. For instance, the International Energy Agency (IEA) states that energy-efficient AC motors can save up to 30% on energy costs, making them a cost-effective choice for industries aiming to reduce operational expenses while complying with sustainability standards. As industries increasingly focus on automation and energy efficiency, understanding these key components becomes essential for optimizing performance and minimizing environmental impact.

Understanding AC Motors: Powering Modern Technology

Types of AC Motors: Choosing the Right One for Your Needs

When it comes to selecting the right AC motor for specific applications, understanding the different types available is crucial. The two primary types of AC motors are synchronous and asynchronous (or induction) motors. Synchronous motors operate at a constant speed that matches the supply frequency, making them ideal for applications requiring precise speed control. According to a recent market report by Research and Markets, the global synchronous motor market is expected to grow at a CAGR of 5.4% from 2021 to 2026, highlighting their increasing relevance in industries like manufacturing and renewable energy.

On the other hand, asynchronous motors are more commonly used due to their simplicity and robustness. These motors are perfect for high-torque applications where variable speeds are less critical. The International Electrotechnical Commission (IEC) estimates that approximately 70% of all industrial motors in use today are induction motors, underscoring their dominance in the market. When choosing between these two types, consider the operational environment, load requirements, and budget constraints.

Tips: Always assess the energy efficiency of the motor; selecting high-efficiency AC motors can significantly reduce operational costs. Additionally, pay attention to the starting requirements of your application; some motors may require soft starters or VFDs (Variable Frequency Drives) to enhance performance.

How AC Motors Enhance Efficiency in Modern Industrial Applications

AC motors have become a cornerstone of modern industrial applications, significantly enhancing efficiency across various sectors. According to a report by the International Electrotechnical Commission (IEC), AC motors account for approximately 65% of total industrial motor energy consumption globally. This statistic highlights their critical role in driving machinery in manufacturing, HVAC systems, and other industrial setups. The design of AC motors, particularly the induction motor, enables higher efficiency rates—often exceeding 90%—when compared to other motor types.

One of the key advantages of AC motors is their ability to operate at optimal efficiency under varying load conditions. The U.S. Department of Energy (DOE) estimates that improving the efficiency of electric motors could save up to 30% of energy consumption in industrial settings. This efficiency is not only economically beneficial—reducing energy costs and boosting productivity—but also environmentally friendly, as lower energy consumption results in reduced greenhouse gas emissions. As industries continue to prioritize sustainability, the implementation of advanced AC motor technologies, such as variable frequency drives (VFDs), is becoming increasingly common, further enhancing their performance and adaptability in modern applications.

Maintaining Your AC Motor: Essential Tips for Longevity

When it comes to maintaining the longevity of your AC motor, proactive care and regular maintenance are essential. One key tip is to ensure that the motor is adequately ventilated. Overheating can lead to premature wear, so it's crucial to keep air intake and exhaust areas clear of obstructions. Additionally, regularly checking and cleaning the cooling vents can help maintain optimal temperature levels during operation.

Another important aspect is lubrication. Ensure that all moving parts are properly lubricated according to the manufacturer's recommendations. A lack of lubrication can cause friction, leading to increased wear and potential failure. Using the right type of lubricants and applying them at regular intervals can significantly extend the life of your motor and improve its efficiency.

Lastly, inspecting electrical connections is vital. Loose or corroded wiring can lead to poor performance and overheating. Regularly checking connections, tightening loose wires, and cleaning any corrosion will help maintain reliable operation and reduce the risk of unexpected breakdowns. By following these essential tips, you can ensure that your AC motor continues to power technology and industry effectively for years to come.

Future Trends in AC Motor Technology: What to Expect in the Coming Years

As the industrial automation market is projected to grow significantly, with an estimated increase from $205.86 billion in 2022 to $395.09 billion by 2029 at a compound annual growth rate of 9.8%, the importance of AC motors cannot be overstated. These motors are fundamental to powering various automated processes and equipment used in industries, making them a vital component in enhancing productivity and efficiency. The advancement in AC motor technology is closely linked to this growth, as innovations continue to improve energy efficiency, reliability, and performance.

Looking ahead, the AC motor landscape is expected to evolve with new capabilities driven by trends such as electrification and the focus on sustainable practices. In particular, the rise of electric vehicles (EVs) is shaping the future of motor technologies, with a notable expansion in the market for electric drivetrains. By 2025, the global electric vehicle market is anticipated to reach a value of $155.4 billion, further fueling the demand for efficient AC motors. This trajectory indicates not only an improvement in motor designs but also a shift towards more integrated and smart solutions, leveraging connectivity and advanced control systems to meet the needs of modern technology and industry.

Related Posts

-

Empowering Your Operations: Discovering Benefits of 3ph Electric Motors for Global Sourcing

-

Solutions for Outstanding Performance in Asynchronous Motors

-

5 Best AC Motor Options for Enhanced Efficiency and Performance in 2023

-

Unlocking the Future: How Break Motors Revolutionize Modern Machinery Efficiency

-

The Pride of China Delivering Best Break Electric Motors to the World

-

5 Powerful Reasons to Choose the Best Three Phase AC Motor for Your Business

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top