Unlocking Efficiency: The Ultimate Guide to Frequency Converters in Industrial Applications

In today's rapidly advancing industrial landscape, efficiency and energy savings are paramount concerns for businesses aiming to enhance their operational performance.

Industry experts have recognized the transformative impact of frequency converters on operational efficiencies. John M. Walker, a leading expert in industrial automation, stated,

"The integration of frequency converters not only improves energy efficiency but also enhances the performance of machines, leading to significant reductions in operating costs.”

As industries continue to seek innovative solutions for their automation needs, understanding the capabilities and applications of frequency converters becomes crucial. This guide aims to unravel the intricacies of frequency converters, providing insights into their benefits and best practices in industrial applications, empowering businesses to make informed decisions that drive efficiency and innovation.

Key Advantages of Using Frequency Converters in Industry

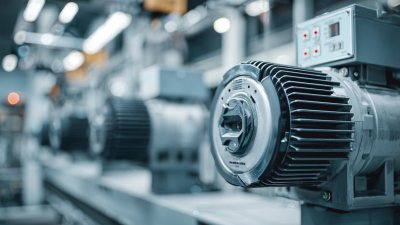

In today's competitive industrial landscape, frequency converters play a pivotal role in enhancing operational efficiency. These devices are essential for controlling the speed and torque of electric motors, which can lead to significant energy savings and improved productivity. One of the key advantages of using frequency converters is their ability to optimize power consumption, allowing industries to operate machinery at variable speeds according to real-time demand. This adaptability not only minimizes energy waste but also extends equipment life, resulting in lower maintenance costs.

Tip: When selecting a frequency converter, consider its compatibility with existing equipment and the specific voltage and power requirements of your application. This ensures seamless integration and optimal performance.

Another notable benefit of frequency converters is their capacity for soft starting motors. By reducing the starting torque and allowing for a gradual ramp-up of speed, these converters prevent mechanical stress on the system. This not only enhances the longevity of the equipment but also decreases the chances of production downtime caused by mechanical failures.

Tip: Regularly monitor the performance of your frequency converters and implement maintenance schedules to ensure they are functioning efficiently, thus maximizing the advantages they bring to your operations.

Top 5 Applications of Frequency Converters in Manufacturing

Frequency converters, also known as variable frequency drives (VFDs), play a crucial role in various manufacturing settings by adjusting motor speed and improving energy efficiency. One of the most significant applications is in conveyor systems, where frequency converters help control the speed and direction of conveyors, enhancing productivity and reducing wear and tear on equipment. By maintaining optimal speeds, manufacturers can ensure a smooth flow of materials while minimizing energy consumption.

Another key application is in pumps and fans. Frequency converters allow for precise control of fluid dynamics, enabling manufacturers to adjust the flow rates based on real-time needs. This adaptability not only conserves energy but also extends the operational life of pumps and fans by reducing the strain associated with constant high-speed operations. Additionally, frequency converters are widely utilized in HVAC systems, providing significant energy savings and better climate control within industrial facilities by modulating fan speeds based on varying load conditions.

Factors to Consider When Selecting a Frequency Converter

When selecting a frequency converter for industrial applications, several crucial factors must be taken into account to ensure optimal performance and efficiency. One of the primary considerations is the converter's power rating. According to a report by Research and Markets, the global frequency converter market is projected to reach $4.9 billion by 2024, highlighting the increasing importance of choosing the right equipment to meet specific power requirements. Ensure that the frequency converter can handle the operational loads without overheating or underperforming.

Additionally, the application type significantly influences the selection process. For instance, variable torque applications like pumps and fans typically require different specifications compared to constant torque applications such as conveyors. A study by the International Energy Agency suggests that using frequency converters can improve energy efficiency by 20-50% in these applications. Therefore, understanding the specific requirements of your application will guide you toward a suitable converter.

**Tips:** Always consider the environmental conditions in which the converters will operate. Outdoor settings may require units with IP ratings for better protection against dust and moisture. Another essential tip is to evaluate the converter's control capabilities, such as integration with existing automation systems, to enhance operational efficiency further.

Emerging Trends in Frequency Converter Technology

Emerging trends in frequency converter technology are shaping the future of industrial applications, especially as the demand for efficient energy solutions continues to rise. With the global grid-forming inverter market projected to grow significantly, reaching an estimated value of $1.579 billion by 2032, advancements in frequency conversion are crucial. The robust development of power semiconductor technology, particularly with IGBT domestication, reinforces the essential role of frequency converters in enhancing voltage and frequency modulation across electronic systems.

Tip: For industries looking to optimize efficiency, investing in high-voltage frequency converters can provide substantial long-term benefits. These devices are not only vital for automation but also contribute to energy savings in operations, reducing overall operational costs.

Furthermore, the integration of cutting-edge technologies such as MEMS and NEMS in resonators allows for compact and cost-effective solutions in frequency conversion. The capabilities of these technologies enhance performance metrics in various applications, from clock oscillators to RF filters, thereby broadening the horizon for potential uses in industrial settings.

Tip: Stay updated with the latest trends in frequency converter innovations to leverage new technologies that can enhance operational efficiency. Actively seek solutions that incorporate the latest semiconductor developments for improved system reliability.

Maintenance Best Practices for Frequency Converters in Operations

Proper maintenance of frequency converters is crucial for ensuring optimal performance and prolonging the life of these vital components in industrial operations. One of the best practices involves regular inspections of the equipment to identify any signs of wear, corrosion, or damage. Cleaning is another essential task; dust and debris can accumulate and impair performance. Scheduled cleaning of both the internal and external parts of the frequency converter can prevent overheating and ensure smooth functionality.

Additionally, monitoring the operating conditions can help in maintaining efficiency. Keeping an eye on parameters such as temperature, load, and input voltage allows for early detection of potential issues. It is equally important to update firmware and software regularly to benefit from the latest features and security enhancements. Implementing a predictive maintenance strategy, which uses data analysis to predict failures before they occur, can further enhance reliability and minimize unexpected downtime. By adhering to these best practices, industries can ensure that their frequency converters operate at peak efficiency, ultimately leading to improved operational productivity.

Frequency Converters Maintenance Best Practices

Related Posts

-

How to Choose the Right Frequency Converter for Your Industrial Needs

-

Empowering Global Industries: Quality Frequency Converters from China's Leading Manufacturers

-

Exploring the Features and Applications of Best Variable Frequency Motors with Buying Tips

-

How to Choose the Right Frequency Converter for Your Industrial Needs

-

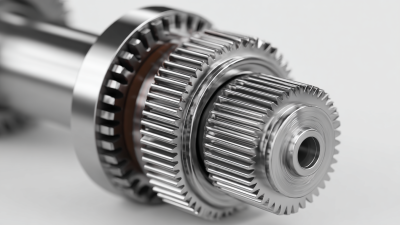

Understanding How Gear Reducers Improve Efficiency in Modern Machinery

-

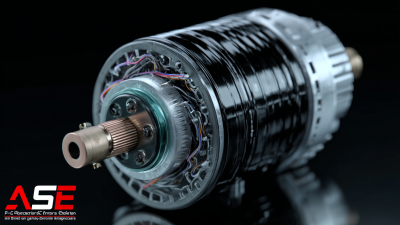

The Future of Innovation in Best 3ph Electric Motor Technology

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top