Top 10 Induction Motor Types for Optimal Performance and Efficiency

Induction motors have become a cornerstone of modern industrial applications due to their reliability, efficiency, and relatively low maintenance requirements. As one of the most common types of electric motors, they are used in a wide range of settings, from manufacturing plants to household appliances. Understanding the various types of induction motors available is crucial for optimizing performance and energy efficiency in any application. This article will delve into the top 10 induction motor types, highlighting their unique features, operational advantages, and the specific scenarios in which they excel.

Selecting the right induction motor can significantly impact the overall effectiveness of machinery and operational costs. Each type of induction motor offers distinct advantages, whether it be through design variations, efficiency ratings, or specialized applications. By exploring these options, engineers and decision-makers can ensure that they are choosing the most suitable motor for their specific needs. This comprehensive guide aims to illuminate the diverse selection of induction motors, empowering readers to make informed choices that align with their performance and efficiency goals.

Overview of Induction Motors and Their Importance in Industry

Induction motors are pivotal in various industrial applications, providing reliable and efficient performance for countless operations. These motors convert electrical energy into mechanical energy using electromagnetic induction, making them particularly advantageous for applications requiring constant speed. Their robust design, minimal maintenance needs, and ability to operate in harsh environments contribute to their widespread usage in manufacturing, processing plants, and other industrial settings.

Tips for optimal performance include ensuring proper alignment and installation, which can significantly reduce wear and tear on the motor. Regular inspections and maintenance routines, such as monitoring temperature and vibration levels, are also essential to prevent unexpected downtimes. Utilizing the appropriate starter type for an induction motor can enhance its efficiency further, ensuring a smooth start and prolonged lifespan.

Choosing the right induction motor type for your specific application is crucial for maximizing efficiency. Considerations such as load requirements, operational environment, and the motor's duty cycle can significantly impact performance. By understanding these factors and implementing proactive maintenance strategies, industries can harness the full potential of induction motors, leading to improved productivity and energy savings.

Types of Induction Motors Based on Rotor Design and Application

Induction motors are widely recognized for their robustness and reliability, making them suitable for a variety of industrial applications. When it comes to rotor design, induction motors primarily fall into two categories: Squirrel Cage and Wound Rotor motors. Squirrel Cage motors are favored for their simple construction and minimal maintenance requirements. Their rotor consists of conductive bars shorted at both ends, allowing them to operate efficiently across various loads. This type of motor is ideal for applications where continuous operation is needed, such as in fans, pumps, and conveyors.

On the other hand, Wound Rotor motors possess a more complex structure featuring windings on the rotor, which allows for better control of speed and torque. This design is particularly beneficial in applications requiring high starting torque or variable speed operations, such as in crushers or mills. The ability to fine-tune performance using external resistors connected to the rotor makes Wound Rotor motors suitable for heavy-duty applications.

**Tips:** When selecting an induction motor for your application, consider factors like torque requirements, load characteristics, and operating conditions. It’s also beneficial to consult with an expert to ensure optimal motor sizing and performance tailored to your specific operational needs. Always prioritize regular maintenance checks to enhance the longevity and efficiency of your induction motors, regardless of the rotor type.

Top 10 Induction Motor Types for Optimal Performance and Efficiency

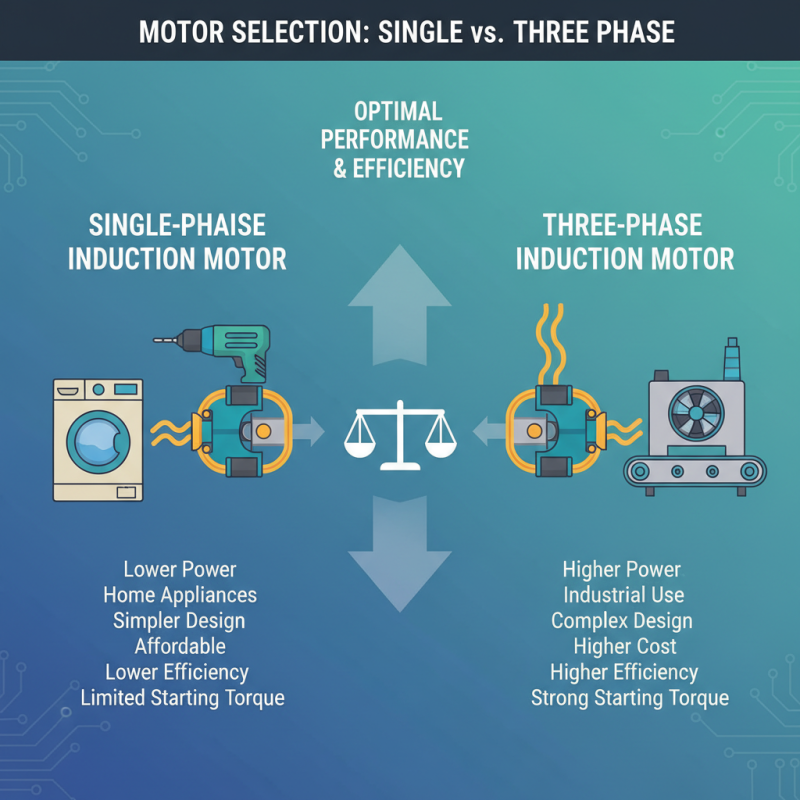

Comparison of Single-Phase and Three-Phase Induction Motors

When it comes to choosing between single-phase and three-phase induction motors for optimal performance and efficiency, understanding their differences is crucial. Single-phase induction motors are typically used in lower-power applications, such as household appliances and small tools. They operate on a single-phase power supply and are generally simpler in design, making them more affordable. However, their efficiency and starting torque can be lacking compared to their three-phase counterparts. This can limit their effectiveness in larger or more demanding applications.

On the other hand, three-phase induction motors are known for their superior efficiency and higher power output. They operate on a three-phase power supply, which allows for a more balanced load and smoother operation. This feature translates to better torque performance and reduced vibration, making them ideal for industrial applications where power and reliability are paramount. Additionally, three-phase motors often have a longer lifespan and require less maintenance, further enhancing their efficiency.

Tips: When selecting an induction motor, assess the specific requirements of your application. If you’re in a residential or light commercial setting, a single-phase motor may suffice. But for industrial use, investing in a three-phase motor can lead to significant long-term benefits in terms of efficiency and operational reliability. Always consider the availability of power supply and the expected load characteristics before making your choice.

Factors Influencing the Performance and Efficiency of Induction Motors

The performance and efficiency of induction motors can be significantly influenced by various factors. One primary aspect is the design of the motor itself, including rotor and stator configurations. A well-designed rotor can enhance the magnetic field interaction, leading to improved torque and operational efficiency. Additionally, the choice of materials used in the construction of the motor plays a critical role. High-quality electrical steel, for example, can reduce energy losses due to hysteresis and eddy currents, making the motor more efficient.

Moreover, operating conditions such as temperature, load fluctuations, and supply voltage stability are crucial in determining efficiency. Elevated temperatures can increase resistive losses, while varying loads may lead to inefficient operation if the motor is not appropriately sized. Furthermore, power quality issues, such as harmonic distortions in the supply voltage, can adversely affect the performance of induction motors. Regular maintenance, including the inspection of bearings and alignment, can also contribute to optimal efficiency, ensuring that the motor operates smoothly and with minimal energy waste.

Future Trends in Induction Motor Technology and Innovations

Induction motor technology is experiencing rapid advancements, driven by the increasing demand for energy efficiency and sustainable solutions across various industries. Recent reports highlight a projected growth rate of over 8% in the global induction motor market through 2025, underscoring the relevance of innovations in this sector.

One key trend is the integration of IoT technology, enabling real-time monitoring and predictive maintenance. By leveraging data analytics, manufacturers can optimize motor performance and reduce downtime, enhancing operational efficiency in industrial settings.

Another significant trend is the development of high-efficiency motors that meet or exceed the standards set by international regulations. The adoption of advanced materials, such as silicon steel and magnet wire, contributes to substantial energy savings—approximately 20% compared to traditional motors, according to a report by the International Energy Agency (IEA).

Additionally, the shift towards variable frequency drives (VFDs) allows for greater control over motor operation, resulting in improved energy use and reduced wear on equipment. As industries continue to prioritize sustainability, these innovative technologies will play a crucial role in shaping the future of induction motors.

Related Posts

-

Rising Above Tariffs: How China's Best Induction Motors Thrive in a Competitive Market

-

Rising Above Tariff Challenges: How China's Best Electric Motor Manufacturers Thrive

-

The Pride of China Delivering Best Break Electric Motors to the World

-

Quality Induction Motors Made in China Setting New Standards for Global Procurement

-

Exploring Innovative Applications of Induction Motors Across Different Industries

-

How to Choose the Right Electric Motor for Your Specific Needs

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top