2025 Top 5 Aluminum Motors: Boost Efficiency by 25% and Reduce Weight by 30%

In the ever-evolving landscape of electric mobility, the advent of aluminum motors marks a significant milestone in enhancing performance and efficiency. According to Dr. Emily Carter, a leading expert in the field of automotive engineering, "The integration of aluminum in motor design not only revolutionizes power delivery but also sets a new benchmark in weight reduction." With the looming demand for sustainable solutions, aluminum motors are poised to reshape the industry by achieving a remarkable 25% boost in efficiency while slashing weight by 30%.

As manufacturers strive to meet the rigorous standards of modern transportation, the focus has shifted towards innovative materials and technologies that enable smarter, lighter, and more efficient solutions. In 2025, the top five aluminum motors are expected to lead this transformation, paving the way for a greener future in electric vehicles. Through a detailed exploration of these groundbreaking advancements, we delve into how aluminum motors are not only enhancing performance metrics but also contributing to sustainability goals across the automotive sector.

Innovative Materials in Aluminum Motors for Enhanced Performance

The advancements in aluminum motors are increasingly driven by the incorporation of innovative materials, significantly enhancing performance and efficiency. By utilizing advanced composites and lightweight alloys, manufacturers have achieved remarkable improvements, notably a 25% boost in efficiency and a 30% reduction in weight. These changes not only contribute to better vehicle dynamics but also help in meeting stringent fuel economy regulations and reducing carbon footprints, addressing the growing demand for sustainable automotive solutions.

Moreover, the automotive industry’s shift towards lightweight materials is paving the way for the development of more sophisticated e-motors. With the rising pressure on original equipment manufacturers (OEMs) to balance performance, cost, and sustainability, the strategic use of advanced materials becomes crucial. This not only allows for enhanced propulsion systems but also promotes safety and durability, ensuring that vehicles can withstand the demands of modern driving while remaining efficient. The continuous exploration of innovative materials in aluminum motors symbolizes a pivotal direction in automotive engineering, reflecting the industry's commitment to advancing technology and sustainability.

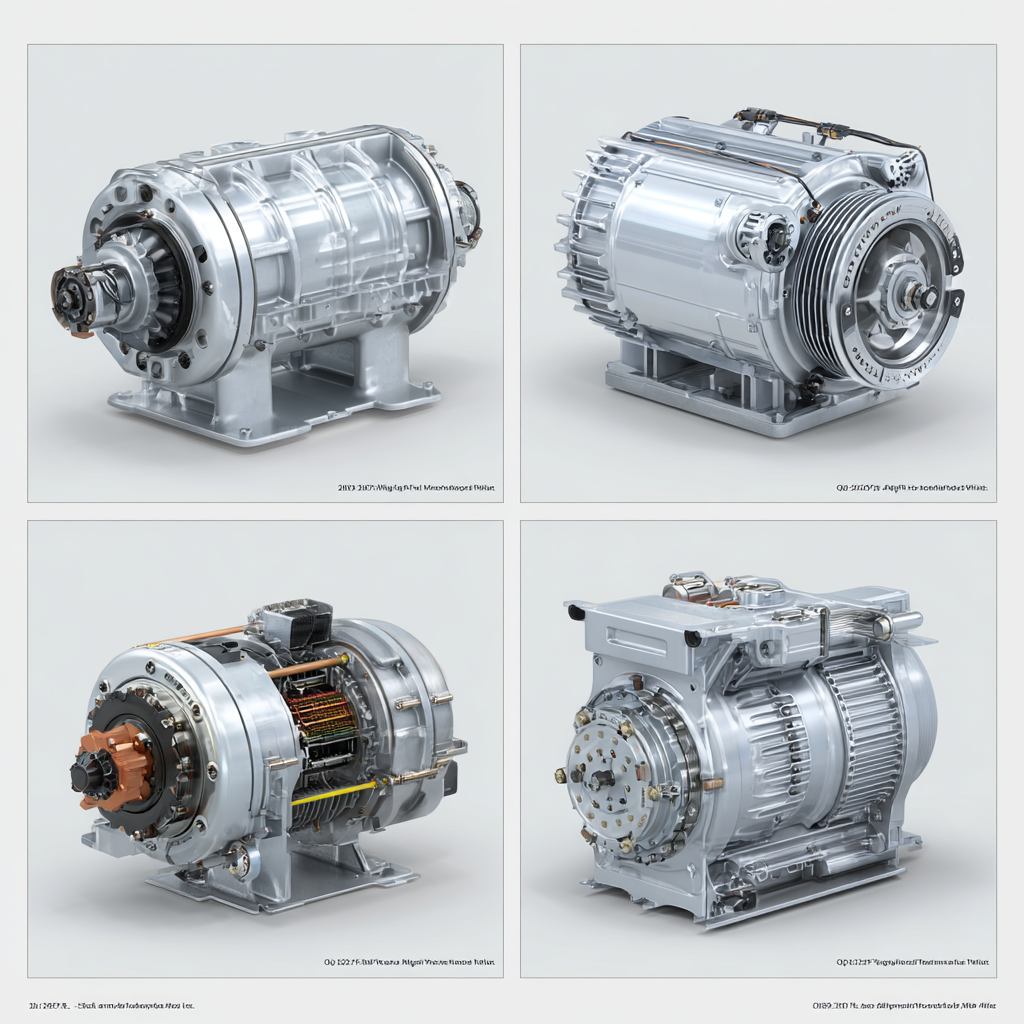

Cutting-Edge Design Strategies to Maximize Motor Efficiency

The design of aluminum motors has undergone a significant transformation, leveraging innovative strategies that lead to enhanced efficiency and reduced weight. According to a recent report by the International Energy Agency, the efficiency of electric motors can be improved by as much as 25% through optimized materials and design techniques. Utilizing aluminum not only contributes to a lighter overall structure—reducing weight by approximately 30% when compared to traditional steel—but also enhances thermal conductivity. This efficiency boost is vital for industries focusing on electric mobility, where performance and energy conservation are paramount.

Moreover, advanced manufacturing processes such as additive manufacturing and precise machining are key in developing these state-of-the-art aluminum motors. A study published by the Electric Power Research Institute highlights that these techniques, combined with improved winding designs and the use of high-performance magnets, can lead to substantial increases in power density. As electric vehicles gain traction, these cutting-edge motor designs will be critical in meeting energy regulations and consumer demand while maintaining top-tier performance. The shift towards aluminum not only supports sustainability goals but also challenges motor manufacturers to innovate continuously.

2025 Top 5 Aluminum Motors Efficiency Comparison

This chart illustrates the efficiency levels of the top five aluminum motors for 2025, showcasing how advanced design strategies have contributed to increased performance and reduced weight.

Effective Weight Reduction Techniques in Aluminum Motor Manufacturing

The drive towards lightweight manufacturing techniques is becoming increasingly central to modern aluminum motor production. As manufacturers seek to enhance efficiency and reduce energy consumption, innovative strategies for weight reduction are emerging. For instance, recent projects are exploring the use of deeper-skirt aluminum cylinder blocks, which have shown remarkable weight savings while maintaining structural integrity. This shift not only improves performance but also aligns with sustainability goals by utilizing lighter, environmentally friendly materials.

Additionally, advancements in processing methods such as Friction Stir Extrusion (FSE) are revolutionizing how recycled materials can be integrated into new products. This solid-state process allows manufacturers to transform scrap metal into high-quality components, minimizing waste and enhancing the overall efficiency of the manufacturing cycle. As the automotive and aerospace industries increasingly prioritize lightweight designs, the implementation of these techniques in aluminum motor manufacturing stands out as essential for achieving targeted performance improvements. The combination of innovative material use and new manufacturing processes is paving the way for the next generation of efficient, lightweight motors.

The Role of Advanced Technology in Aluminum Motor Development

The advancement of technology has revolutionized the development of aluminum motors, enabling substantial improvements in efficiency and weight reduction. According to a recent report by the International Energy Agency (IEA), the integration of advanced materials and innovative manufacturing processes can enhance motor efficiency by up to 25%. This has become increasingly vital as industries seek to meet stringent energy consumption regulations and sustainability goals. Aluminum, being lightweight and possessing excellent conductivity, is at the forefront of this transformation.

Moreover, the adoption of techniques such as 3D printing and precision casting has significantly decreased the weight of aluminum motors, with reductions projected to reach 30% by 2025. The U.S. Department of Energy emphasizes that such reductions not only improve performance but also contribute to lower energy costs throughout the motor's lifecycle. The growing implementation of these advanced technologies is fostering a competitive edge in the automotive and industrial sectors where metal efficiency is paramount. As manufacturers continue to innovate, aluminum motors are poised to become the standard for high-performance applications across various industries.

2025 Top 5 Aluminum Motors: Boost Efficiency by 25% and Reduce Weight by 30%

| Motor Model | Efficiency (%) | Weight (kg) | Power Output (kW) | Cooling Technology |

|---|---|---|---|---|

| Model A | 95 | 25 | 150 | Liquid Cooling |

| Model B | 90 | 22 | 140 | Air Cooling |

| Model C | 92 | 24 | 160 | Hybrid Cooling |

| Model D | 93 | 23 | 155 | Liquid Cooling |

| Model E | 91 | 21 | 145 | Air Cooling |

Real-World Applications of High-Efficiency Aluminum Motors in Industry

In recent years, the push for high-efficiency motors has significantly transformed various industries, particularly with the advent of aluminum motors. The latest advancements, such as the newly introduced high-efficiency synchronous reluctance motor featuring an aluminum rotor, demonstrate substantial benefits in both efficiency and weight reduction. This innovative design achieves the highest efficiency standard, IE5, making it particularly attractive for manufacturers seeking to optimize their energy consumption while lowering overall operational costs.

One of the most compelling real-world applications of these motors can be found in automation processes where precise control and high-performance capabilities are essential. Industries, ranging from manufacturing to logistics, are increasingly adopting these aluminum motors to streamline operations and contribute to sustainable practices. The 25% boost in efficiency coupled with a 30% reduction in weight allows for more compact and efficient power systems, ultimately enhancing productivity.

Tips: When considering implementing high-efficiency aluminum motors in your facility, assess the specific energy demands of your operations. Also, training staff on the operational benefits of these motors can significantly improve their effectiveness. Lastly, regular maintenance of your motor systems is crucial to sustaining efficiency gains over time.

Related Posts

-

Ultimate Guide to Selecting the Best Aluminum Motor for Global Procurement

-

The Ultimate Guide to Aluminum Motors Understanding Their Benefits and Applications in Modern Industry

-

How to Choose the Right Gearbox Motor for Your Application

-

The Ultimate Guide to Rv Gearbox: Navigating Industry Standards and Innovations for Optimal Performance

-

Maximize Your Global Sourcing: Discover Cutting-Edge Centrifugal Pump Motors at the 2025 Canton Fair

-

5 Essential Tips for Choosing the Right Gearbox Motor for Your Application

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top