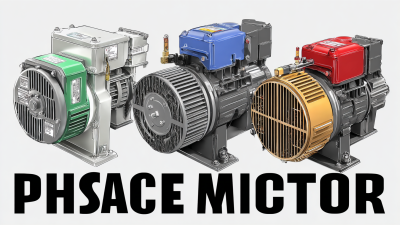

Why Choose a Three Phase Ac Motor for Your Applications?

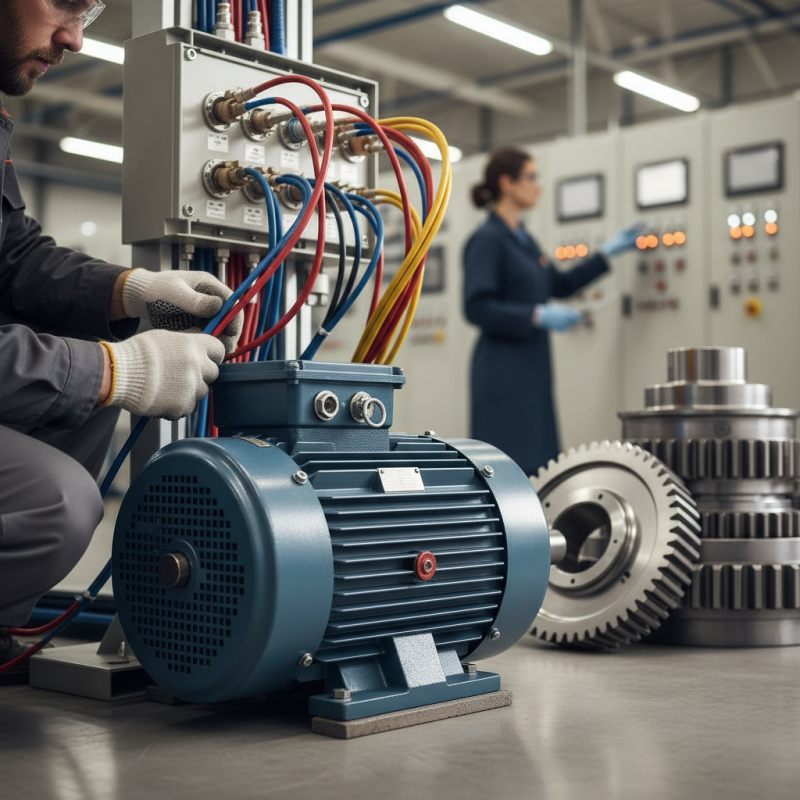

Choosing the right motor can make a difference in your applications. A renowned expert in the field, Dr. Emily Chen, states, “A Three Phase AC Motor is often the best choice for efficiency and reliability.” This powerful motor type offers benefits that are hard to overlook.

Three Phase AC Motors provide consistent power. Their design allows for smooth operation and better torque. This means they can handle heavy loads with ease. However, they also require more complex installations. Proper knowledge about wiring and connections is vital. Mistakes can lead to inefficiencies or even damage.

Additionally, while they are more efficient, they come with higher costs. This initial investment may concern some users. Yet, the long-term savings on energy consumption can be significant. It's essential to weigh these aspects carefully. A Three Phase AC Motor might be the right fit for many applications. But it’s crucial to consider all factors before making a decision.

Benefits of Using Three Phase AC Motors in Industrial Applications

Three-phase AC motors are essential for various industrial applications. They provide several key benefits that enhance performance and efficiency. These motors can handle heavier loads effectively. This leads to a significant reduction in operating costs.

One of the main advantages is their higher efficiency compared to single-phase motors. Three-phase motors generally run cooler and require less maintenance. This is critical in environments where downtime can be costly. Smooth performance is another highlight. The continuous power delivery prevents vibrations that can harm machinery over time.

Tips: Consider the voltage and frequency when selecting a motor. Ensure it matches your application requirements. Always consult performance curves for proper sizing.

Reliability is another reason to choose three-phase AC motors. They can start under load, unlike single-phase variants. However, some installations may face challenges. Wiring and installation can be complex. It's crucial to work with a knowledgeable technician to avoid issues.

Tips: Regular inspections can help identify potential problems early. Implement a maintenance schedule for optimal performance.

Comparison with Single Phase AC Motors: Efficiency and Performance

When considering efficiency and performance, three-phase AC motors have distinct advantages over their single-phase counterparts. For industrial applications, three-phase motors are often more efficient. They can achieve a higher power output with less electrical input. This efficiency translates to lower energy costs and a reduced carbon footprint.

Single-phase motors, while simpler, **face limitations in performance**. They struggle with high loads and can suffer from overheating. In contrast, three-phase motors distribute power evenly across their windings. This leads to smoother operation and increased torque. In many cases, they can start under load, something that is a challenge for single-phase motors.

Three-phase systems also have an *innate redundancy*. If one phase fails, the motor can still operate, albeit at reduced capacity. But, this doesn't mean you can ignore maintenance. Regular checks are essential to ensure continued performance. Over time, some may find three-phase systems complicated. Installation can be a learning curve for technicians. Yet, the benefits often outweigh these challenges.

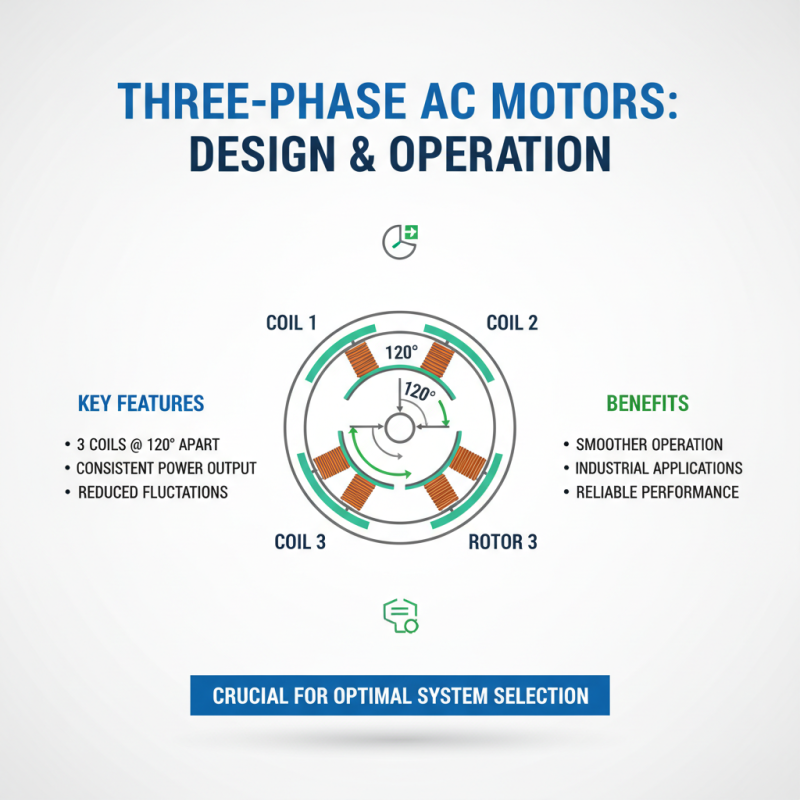

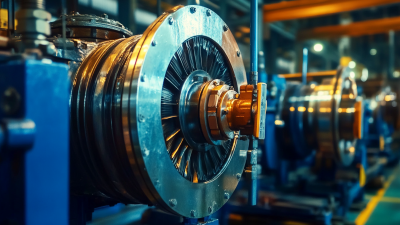

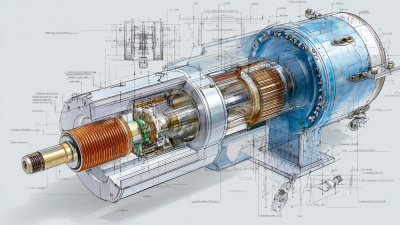

Understanding the Design and Operation of Three Phase AC Motors

Three-phase AC motors play a vital role in various applications. Understanding their design and operation is crucial for selecting the right motor. These motors consist of three coils, each 120 degrees apart. This design provides a consistent power output, reducing fluctuations. The result is a smoother operation, ideal for industrial uses.

The operation of a three-phase AC motor relies on rotating magnetic fields. When alternating current flows through the coils, it generates magnetic fields that interact. This interaction induces a torque on the rotor. As the rotor spins, it maintains synchronization with the magnetic field, ensuring efficient energy conversion. This system can be complex, but its benefits are significant.

However, three-phase AC motors do have challenges. They require a three-phase power supply, which might not always be available. Not every setup can support this. Additionally, understanding their requirements for installation and maintenance can be daunting. Despite these potential hurdles, their advantages make them popular in heavy machinery and automation. Embracing these intricacies can lead to better performance in numerous applications.

Cost Considerations: Initial Investment vs. Long-Term Savings

When considering a three-phase AC motor, cost is a crucial factor. The initial investment can be higher than single-phase motors. However, this disparity is often deceptive. While upfront costs rise, three-phase motors tend to offer longer lifespans and enhanced efficiency. Operational expenses can decrease significantly. For instance, in heavy-duty applications, a three-phase motor can save on energy bills by minimizing power losses.

Maintenance is another consideration. Three-phase motors often require less frequent servicing. This reduction in maintenance needs translates to lower long-term costs. Businesses may overlook this aspect. Initial savings on cheaper motors can lead to larger repair bills down the road. Therefore, understanding the total cost of ownership is vital.

Sometimes, companies rush into decisions without a comprehensive cost analysis. They may choose cheaper options, only to regret it later. Economically, investing in a three-phase motor often pays off. It provides reliable performance and operational savings. Contemplating these factors is essential for making informed choices.

Why Choose a Three Phase AC Motor for Your Applications? - Cost Considerations: Initial Investment vs. Long-Term Savings

| Feature | Single Phase AC Motor | Three Phase AC Motor |

|---|---|---|

| Initial Investment Cost | Lower | Higher |

| Efficiency | 85-90% | 90-95% |

| Maintenance Cost | Moderate | Low |

| Lifespan | 10-15 years | 15-20 years |

| Long-term Savings | Lower | Higher |

| Power Factor | Less optimal | Better |

Common Applications and Industries Utilizing Three Phase AC Motors

Three phase AC motors are widely used across various industries. They provide efficient and reliable performance. Factories rely on them for powering heavy machinery. In manufacturing, they drive conveyor belts and pumps. This enhances productivity and supports continuous operation.

The construction sector also benefits from three phase motors. They power cranes, drills, and mixers. Such equipment often requires high torque and precise control. This type of motor meets those demands effectively. Additionally, in HVAC systems, three phase motors help with large fans and compressors. This ensures consistent air flow and temperature control.

Yet, not every application suits three phase motors. They can be more complex than single phase options. This can lead to higher initial costs. Additionally, maintenance requires skilled technicians. Each project should weigh these factors carefully. The choice should align with specific needs and capacities.

Related Posts

-

A Comprehensive Guide to Understanding AC Motors for Global Buyers

-

How to Choose the Best Three Phase Ac Motor for Your Industrial Needs

-

Ultimate Guide to Selecting the Best Three Phase AC Motor for Your Industrial Needs

-

5 Reasons Why the Best Three Phase AC Motor is Essential for Your Industry Needs

-

Solutions for Outstanding Performance in Asynchronous Motors

-

Unveiling the Specifications of the Best AC Electric Motor: A Comprehensive Technical Review

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top