Top Strategies for Sourcing the Best Low Speed Motor Innovatively and Cost Effectively

In today’s competitive landscape, sourcing the best Low Speed Motor requires a blend of innovation and cost-effectiveness to ensure operational efficiency and sustainability. As industries increasingly pivot towards automation and energy efficiency, the demand for high-performance Low Speed Motors is on the rise. This ultimate guide aims to equip engineers, procurement specialists, and decision-makers with actionable strategies to navigate the complexities of sourcing these vital components.

From understanding the latest technological advancements to evaluating suppliers strategically, we will explore diverse tactics that not only enhance procurement practices but also help in achieving significant cost savings. Whether you are looking to upgrade existing machinery or invest in new projects, leveraging these insights will lead you to the most suitable Low Speed Motor solutions that meet your specific requirements.

Innovative Approaches to Identifying High-Quality Low Speed Motors for Various Industries

In the pursuit of high-quality low-speed motors, innovative sourcing strategies are essential for industries looking to optimize their operations. With the landscape of manufacturing evolving, especially amid China's rapid advancements in technology and innovation, organizations can leverage new approaches to identify and acquire superior motors. This involves not only evaluating the engineering and performance specifications of motors but also exploring partnerships with local manufacturers known for their cutting-edge capabilities. By tapping into the burgeoning ecosystem of innovation, companies can access motors that meet sustainable and efficiency standards without straining their budgets.

In the pursuit of high-quality low-speed motors, innovative sourcing strategies are essential for industries looking to optimize their operations. With the landscape of manufacturing evolving, especially amid China's rapid advancements in technology and innovation, organizations can leverage new approaches to identify and acquire superior motors. This involves not only evaluating the engineering and performance specifications of motors but also exploring partnerships with local manufacturers known for their cutting-edge capabilities. By tapping into the burgeoning ecosystem of innovation, companies can access motors that meet sustainable and efficiency standards without straining their budgets.

Disruptive innovation plays a crucial role in this sourcing process. Understanding how new entrants in the market can shake up traditional supply chains equips businesses to anticipate changes and adapt their strategies accordingly. It's critical to stay informed on emerging technologies and materials that can enhance motor performance while reducing costs. Furthermore, the integration of AI tools helps companies analyze vast datasets to uncover trends and identify the most suitable suppliers—ensuring that sourcing methods are not only innovative but also cost-effective. By prioritizing these forward-thinking strategies, industries can position themselves to secure the best low-speed motors available in the market.

Case Studies Highlighting Successful Applications of Low Speed Motors in Real-World Scenarios

Recent advancements in low speed motor technology have led to innovative applications across various industries, showcasing their versatility and efficiency. For instance, in the realm of autonomous driving, low speed motors play a crucial role in enhancing vehicle maneuverability and energy efficiency. Case studies reveal how manufacturers have integrated these motors into prototypes for testing purposes, significantly improving performance metrics under varying conditions. The adaptive nature of these motors contributes to smoother acceleration and deceleration, thereby enhancing overall driver safety and comfort.

Moreover, the integration of artificial intelligence in energy management has further propelled the application of low speed motors. In energy storage systems, these motors are being utilized to optimize power distribution, ensuring that renewable energy resources can effectively meet consumer demand. Real-world scenarios demonstrate how AI-driven analytics have enabled smarter scheduling of energy usage, ultimately reducing operational costs. Such innovative implementations reflect the growing trend towards cost-effective energy solutions while promoting sustainability and reliability in everyday applications.

Cost-Effective Sourcing Strategies for Low Speed Motors: Tips for Budget-Conscious Buyers

When it comes to sourcing low-speed motors, budget-conscious buyers must adopt cost-effective strategies. One savvy approach is to leverage bulk purchasing. By collaborating with other businesses in need of similar components, you can negotiate better prices on larger orders. This not only reduces the per-unit cost but also strengthens supplier relationships, leading to potential discounts on future purchases.

Another tip is to explore alternative suppliers and manufacturers, particularly those in regions known for competitive pricing. Expanding your search beyond local options can uncover hidden gems that offer both quality and affordability. Additionally, consider reaching out to emerging manufacturers who may be eager to build their portfolio and willing to negotiate favorable terms.

Lastly, staying updated on industry trends and technological advancements can provide leverage in negotiations. Being informed about recent innovations in low-speed motors may give you the upper hand when discussing pricing or features with suppliers. This knowledge can also help you identify which products are truly worth the investment, ensuring you make informed, budget-friendly decisions.

Top Strategies for Sourcing the Best Low Speed Motor Innovatively and Cost Effectively

| Strategy | Description | Expected Savings (%) | Implementation Difficulty (1-5) |

|---|---|---|---|

| Supplier Negotiation | Engaging suppliers to secure better pricing and terms through negotiation. | 10-20% | 3 |

| Bulk Purchasing | Purchasing in large quantities to take advantage of discounts. | 15-25% | 4 |

| Vendor Review | Evaluating and selecting vendors based on performance and cost-effectiveness. | 5-15% | 2 |

| Alternative Materials | Researching and utilizing alternative materials to reduce costs. | 10-30% | 3 |

| Technology Integration | Implementing advanced manufacturing technology to enhance efficiency. | 20-40% | 5 |

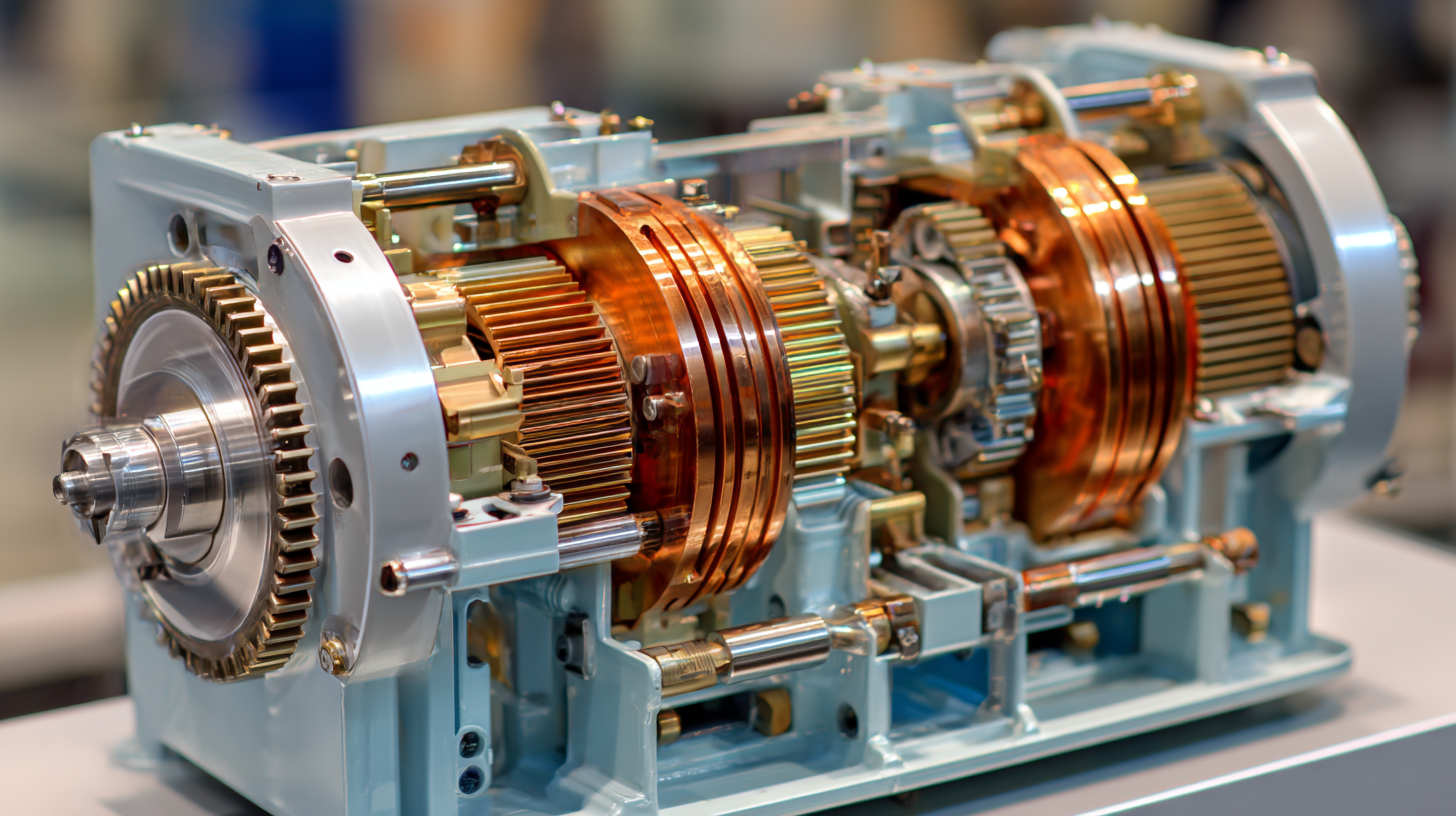

Understanding Different Types of Low Speed Motors and Their Unique Advantages

When it comes to low speed motors, understanding the various types and their unique advantages is crucial for making informed sourcing decisions. Low speed motors are primarily categorized into DC motors, AC motors, and stepper motors, each serving specific applications and offering distinct benefits. DC motors, for instance, are well-regarded for their simplicity and ease of speed control, making them ideal for applications that require precise adjustments. Their efficiency and relatively low cost make them a popular choice in various industries.

On the other hand, AC motors are typically used in applications where reliability and durability are paramount. They tend to have fewer maintenance requirements and can operate effectively at constant speeds, which is advantageous in settings like conveyor systems and manufacturing processes. Additionally, stepper motors offer exceptional positional accuracy and are commonly employed in robotics and computer-controlled machinery. Their ability to move in discrete steps facilitates precise movement, making them indispensable in applications requiring high precision.

Each type of low speed motor presents unique advantages that cater to specific industrial needs. Understanding these distinctions allows manufacturers and engineers to choose the right motor, optimizing performance while managing costs effectively.

Evaluating Performance Metrics: How to Choose the Right Low Speed Motor for Your Needs

When selecting the right low-speed motor for your applications, evaluating performance metrics is essential to ensure optimal functionality and longevity. Start by considering the torque requirements; the motor must produce sufficient torque to handle the loads efficiently. Higher torque ratings can benefit industrial applications, where demanding conditions are commonplace. Additionally, examine the efficiency ratings, as these determine how effectively the motor converts electrical energy into mechanical energy. A motor with higher efficiency will not only reduce energy costs but also minimize heat generation, contributing to a longer lifespan.

Another critical aspect is the operational environment of the motor. Factors such as temperature, humidity, and potential exposure to dust or corrosive elements can significantly impact performance. Look for motors with appropriate ingress protection ratings to withstand harsh conditions. Finally, analyzing the speed range is crucial. Depending on the desired application, you may require a motor capable of precise speed adjustment or one that operates ideally within a specific speed threshold. Ensuring that the motor aligns with your specific performance metrics will result in more reliable operation and enhanced functionality.

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top