Ultimate Guide to Selecting the Best Three Phase AC Motor for Your Industrial Needs

In the dynamic landscape of industrial applications, selecting the right Three Phase AC Motor is pivotal for optimizing efficiency and performance. According to a recent report by the International Electrotechnical Commission (IEC), three phase motors account for around 70% of the total electric motor market, underscoring their critical role in modern manufacturing processes. With advancements in technology and increasing energy efficiency regulations, businesses are challenged to navigate the myriad of options available. The right motor can lead to significant cost savings, improved operational reliability, and reduced downtime. This ultimate guide aims to provide top strategies for selecting the best Three Phase AC Motor tailored to your unique industrial needs, ensuring that you make informed decisions backed by industry insights and trends.

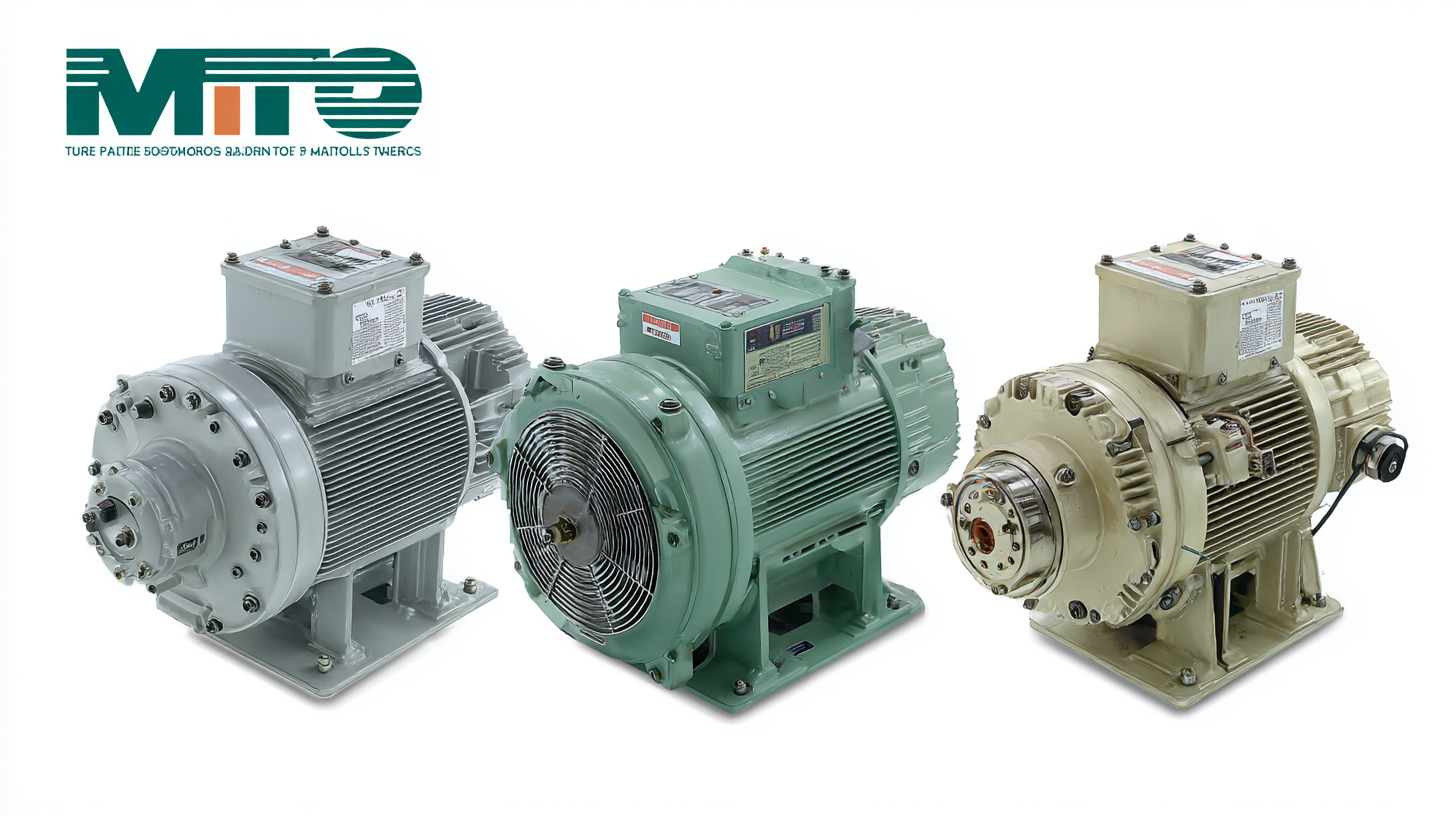

Understanding the Basics of Three Phase AC Motors in Industrial Applications

Three phase AC motors are a critical component in various industrial applications, providing efficiency and reliability for a multitude of processes. Understanding the basics of these motors is essential for selecting the right one for your operational needs. Unlike single phase motors, three phase motors use three alternating currents that are 120 degrees out of phase. This configuration allows for a smoother and more consistent power delivery, enabling higher torque and reduced vibrations during operation.

When choosing a three phase AC motor, consider the load requirements of your application. It's important to match the motor's power capacity with the demands of the machinery it will drive. Oversizing or undersizing a motor can lead to inefficiencies and premature wear.

Tip: Always refer to the manufacturer's specifications and consult with experts if needed. This careful approach can help avoid costly mistakes in the selection process.

Additionally, understanding the starting methods for three phase motors, such as direct-on-line (DOL) or star-delta starting, can influence your decision. These methods impact the motor's performance and startup characteristics, which are crucial for ensuring smooth operation.

Tip: Evaluate the electrical supply and installation environment, as this will guide you in selecting the most suitable starting method to optimize your motor's efficiency and lifespan.

Key Factors to Consider When Selecting a Three Phase AC Motor

When selecting the best three-phase AC motor for your industrial needs, several key factors come into play. First and foremost, you should assess the load requirements. It’s crucial to match the motor's horsepower to the application, ensuring adequate torque and efficiency. Consider the operational environment as well; high temperatures, humidity, or corrosive substances can influence the choice of motor material and insulation.

**Tip:** Always refer to the service factor of the motor, which provides insight into how much overload it can handle under specific conditions. This can help prevent premature failure and enhance overall reliability.

Another important factor is the motor's efficiency rating. Higher efficiency motors may have a higher upfront cost but can save significant energy in the long run. Additionally, pay attention to the starting method and control systems compatible with your facility’s existing infrastructure.

**Tip:** A soft starter can improve performance and reduce stress on both the motor and the connected equipment, leading to greater longevity.

Types of Three Phase AC Motors and Their Unique Characteristics

When selecting a three-phase AC motor for industrial applications, understanding the different types and their unique characteristics is crucial. Three-phase AC motors are primarily categorized into synchronous and asynchronous motors. Synchronous motors operate at a constant speed, which is synchronized with the supply frequency. They are ideal for applications requiring precise speed control and high starting torque. This makes them suitable for pumps, conveyors, and fans operating under varying loads.

On the other hand, asynchronous motors, commonly referred to as induction motors, are the most prevalent type due to their robustness and simplicity. They do not require external power for starting and are inherently self-starting, making them a cost-effective choice for many industrial applications. Induction motors can be further divided into squirrel cage and wound rotor designs, each with specific benefits. Squirrel cage motors are highly reliable and typically used in fixed shaft applications, while wound rotor motors provide better performance under variable load conditions. Understanding these characteristics helps in making an informed choice tailored to the specific needs of your industrial processes.

Ultimate Guide to Selecting the Best Three Phase AC Motor for Your Industrial Needs

This chart presents the comparison of different types of three phase AC motors based on their efficiency, torque, and common applications. Understanding these characteristics can help you make informed decisions for your industrial needs.

Efficiency Ratings and Performance Metrics for Three Phase AC Motors

When selecting a three-phase AC motor for industrial applications, understanding efficiency ratings and performance metrics is crucial. According to the U.S. Department of Energy, industrial motors account for about 70% of electricity consumption in manufacturing, highlighting the need for high-efficiency options. The efficiency of a three-phase AC motor can be determined using the Efficiency Ratio (η), which typically ranges from 80% to over 95% for premium efficiency motors. Motors classified as IE3 or IE4 by the International Efficiency Standards have become increasingly popular, as they offer higher performance and lower operational costs compared to standard motors.

Another significant metric is the power factor (PF), which affects the total energy consumption. A higher PF close to 1 indicates better efficiency in power usage. Motors rated with a power factor above 0.9 are commonly preferred in industrial settings, as they can reduce electricity costs significantly. Additionally, considering the speed-torque characteristics is essential for selecting the best motor for specific applications; for instance, a motor providing a high starting torque is often favorable for heavy-duty operations. Combining these efficiency ratings and performance metrics will lead to more informed decisions, ultimately optimizing operational efficiencies in industrial environments.

Ultimate Guide to Selecting the Best Three Phase AC Motor for Your Industrial Needs

| Motor Type | Power Rating (kW) | Efficiency Rating (%) | Torque (Nm) | Speed (RPM) |

|---|---|---|---|---|

| Squirrel Cage Induction Motor | 5 | 92 | 30 | 1500 |

| Permanent Magnet Synchronous Motor | 7.5 | 95 | 45 | 1800 |

| Wound Rotor Induction Motor | 10 | 90 | 60 | 1200 |

| Double Squirrel Cage Induction Motor | 15 | 94 | 75 | 1000 |

Common Applications of Three Phase AC Motors in Various Industries

Three-phase AC motors are essential components in various industrial applications due to their efficiency and reliability. According to a report by the International Energy Agency (IEA), three-phase motors account for approximately 70% of the total energy consumed by electric motors in industrial sectors. This predominance can be attributed to their superior performance in heavy-duty applications where consistent torque and reduced vibration are crucial.

In manufacturing, three-phase AC motors are widely used to power conveyors, pumps, and fans. The National Electrical Manufacturers Association (NEMA) indicates that these motors are particularly favored in processes requiring continuous operation, such as in the automotive and food processing industries. Additionally, in the mining sector, three-phase motors drive crushers and grinders, showcasing their ability to operate under demanding conditions while minimizing maintenance costs. As industries evolve towards automation and smarter solutions, the role of three-phase AC motors becomes increasingly pivotal, reinforcing their importance across various sectors.

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top