7 Compelling Reasons to Choose a Break Electric Motor for Your Machinery Needs

In the ever-evolving landscape of industrial machinery, the choice of motor technology plays a crucial role in operational efficiency and sustainability. With global energy consumption expected to rise by approximately 48% by 2040, as reported by the International Energy Agency (IEA), industries are compelled to seek innovative solutions to reduce their carbon footprint and enhance productivity. Among these solutions, the Break Electric Motor stands out as a pioneering alternative that not only meets stringent energy efficiency standards but also offers superior performance in heavy-duty applications. According to recent market analysis by Research and Markets, the electric motor market is projected to grow significantly, driven by the increasing adoption of automation and the need for reliable power sources. This blog will explore seven compelling reasons to choose a Break Electric Motor, underscoring its advantages over traditional motor types and highlighting its potential in transforming machinery standards across various sectors.

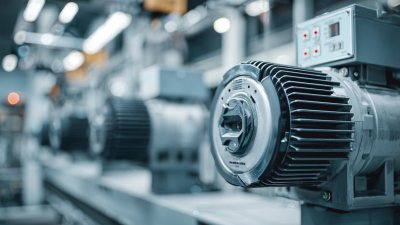

Advantages of Break Electric Motors Over Traditional Options

The advantages of break electric motors over traditional options are compelling, particularly when considering their efficiency and performance. Unlike standard electric motors that may rely heavily on external power sources, break electric motors incorporate innovative designs that optimize energy usage. This not only leads to significant energy savings but also enhances operational efficiency in various machinery applications. Their advanced technology enables smoother performance, reducing wear and tear while extending the lifespan of your equipment.

Moreover, break electric motors offer versatility and adaptability that traditional motors often lack. With the increasing importance of sustainability in today's industrial landscape, these motors present a more eco-friendly option, aligning with the growing trend towards electric and hybrid technologies in transportation. Just as hybrid vehicles combine the benefits of both fuel and electric power for enhanced efficiency, break electric motors harness electrical energy more effectively, ensuring that machinery operates at peak performance without compromising on environmental responsibility. Embracing this technology can result in lower operating costs and a reduced carbon footprint, making it an intelligent choice for forward-thinking industries.

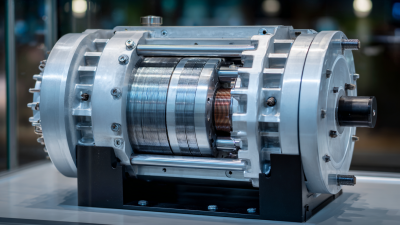

Key Features of Break Electric Motors That Enhance Performance

Break electric motors offer several key features that significantly enhance machinery performance. One of the most prominent characteristics is their superior efficiency. These motors are designed to minimize energy consumption while maximizing output, resulting in lower operational costs. This efficiency not only benefits the budget but also reduces the carbon footprint, making break electric motors an environmentally friendly choice for modern manufacturing processes.

Another essential feature is their advanced control capabilities. Break electric motors often integrate sophisticated electronics that allow precise speed and torque adjustments. This adaptability is crucial for tasks requiring varying power demands, ensuring that machinery operates smoothly under different conditions. Additionally, their durability and low maintenance requirements mean that businesses can rely on break electric motors for continuous operation without the frequent downtime associated with repairs, significantly enhancing productivity and profitability.

Another essential feature is their advanced control capabilities. Break electric motors often integrate sophisticated electronics that allow precise speed and torque adjustments. This adaptability is crucial for tasks requiring varying power demands, ensuring that machinery operates smoothly under different conditions. Additionally, their durability and low maintenance requirements mean that businesses can rely on break electric motors for continuous operation without the frequent downtime associated with repairs, significantly enhancing productivity and profitability.

Cost-Effectiveness of Break Electric Motors in Long-Term Use

When it comes to machinery needs, cost-effectiveness is often a top priority for businesses. Break electric motors shine in this regard, offering significant savings over their operational lifetime. Their energy efficiency is one of the most compelling reasons to invest in them. With advancements in technology, these motors are designed to minimize energy consumption, translating into lower electricity bills for companies that rely on them for heavy operations.

In addition to energy savings, break electric motors require less maintenance compared to traditional alternatives. The reduced wear and tear on components means less frequent servicing and fewer parts replacements, which not only saves costs but also minimizes downtime in production processes. Furthermore, the durability of these motors helps extend their lifespan, offering an impressive return on investment. By choosing break electric motors, businesses can ensure they are making an economically sound decision that supports both their operational efficiency and their budget over the long term.

7 Compelling Reasons to Choose a Break Electric Motor for Your Machinery Needs - Cost-Effectiveness of Break Electric Motors in Long-Term Use

| Reason | Description | Long-Term Cost Impact |

|---|---|---|

| Energy Efficiency | Break electric motors are designed to consume less energy, leading to reduced electricity bills. | Saves approximately 20-30% on energy costs over a decade. |

| Low Maintenance | These motors have fewer moving parts, resulting in lower maintenance needs and costs. | Reduction in maintenance costs by up to 40% over 10 years. |

| Durability | Manufactured to withstand harsh conditions, leading to longer service life. | Potentially 25% longer lifespan compared to traditional motors. |

| High Performance | Provides consistent performance without significant power loss. | Improved productivity translating to higher revenue. |

| Versatility | Can be used in a wide range of applications, making them suitable for various industries. | Reduced need for multiple motor types, savings on inventory and compatibility costs. |

| Environmental Benefits | Lower energy consumption and emissions contribute to a smaller carbon footprint. | Potential tax incentives for energy-efficient operations. |

| Cost-Effective Upfront Investment | While slightly higher initial costs, savings over time justify the investment. | ROI achievable within 3-5 years through savings. |

Environmental Benefits of Choosing Break Electric Motors

When considering machinery needs, choosing a Brake Electric Motor can significantly contribute to environmental sustainability. Unlike traditional motors that often rely on fossil fuels, electric motors operate on clean energy. This shift not only reduces greenhouse gas emissions but also diminishes our dependency on non-renewable resources, making it a responsible choice for eco-conscious businesses.

Furthermore, Brake Electric Motors are designed for energy efficiency, which translates to lower power consumption and reduced operating costs. By implementing these motors, companies can minimize their carbon footprint while also enjoying the economic benefits associated with decreased energy bills. The technology also offers enhanced performance, with less noise pollution and fewer emissions than conventional options, aligning with global efforts to create cleaner industrial environments.

In an era where environmental responsibility is paramount, opting for Brake Electric Motors exemplifies a commitment to sustainable practices. This choice not only benefits the planet but also positions businesses as leaders in the green revolution, appealing to a growing market of environmentally aware consumers.

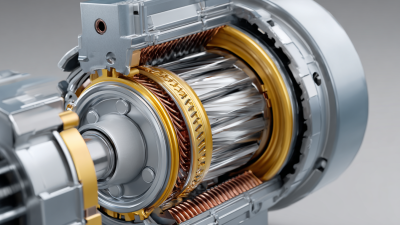

Easy Maintenance and Reliability of Break Electric Motors

When it comes to machinery needs, one of the standout features of break electric motors is their ease of maintenance. According to a report by the Electric Motor Systems Market Analysis, well-designed electric motors can reduce maintenance costs by up to 30%. This is particularly significant for industries that rely on high-performance machinery where downtime can lead to substantial financial losses.

Break electric motors typically come with modular designs, which means that components are easy to access and replace without needing specialized tools or extensive technical knowledge. This results in less operational interruption and enhanced productivity.

Reliability is another prominent advantage of break electric motors. A study conducted by the National Electrical Manufacturers Association revealed that electric motors account for approximately 70% of industrial electricity consumption. Thus, ensuring that these motors are dependable is crucial for maintaining efficiency. Break electric motors are designed for durability and consistent performance, often featuring advanced insulation materials and protective coatings that extend their lifespan, reducing the frequency of replacements and repairs.

By choosing break electric motors, businesses can ensure their machinery operates smoothly, leading to lower overall operational costs and increased output.

Related Posts

-

Empowering Global Industries: Quality Frequency Converters from China's Leading Manufacturers

-

Empowering Your Operations: Discovering Benefits of 3ph Electric Motors for Global Sourcing

-

What is an Aluminum Motor and Why is it Essential for Modern Machinery

-

Exploring the Features and Applications of Best Variable Frequency Motors with Buying Tips

-

Exploring Alternative Technologies for the Best Asynchronous Motor Efficiency and Performance

-

10 Reasons Why the Best AC Motors Outperform Competitors in Efficiency and Longevity

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top