Top 10 Reasons Why Electric Motors Break and How to Fix Them?

Electric motors are vital components in countless industries. They drive everything from small appliances to large machinery, making their reliability crucial. However, industry reports indicate that a staggering 40% of electric motor failures are often due to avoidable reasons. This statistic underscores the importance of understanding why electric motors break, as failures can lead to significant downtime and costly repairs.

Common issues include overheating, which can result from inadequate cooling or overloading. Misalignment and poor installation practices also contribute to reduced motor life. Surprisingly, many operators overlook regular maintenance checks, which could prevent these problems. Realizing that a neglected electric motor is more likely to fail brings awareness to the importance of proactive measures.

As industries aim for efficiency, recognizing the signs of a potential breakdown is critical. Learning to see the early warnings can save companies both time and money. Understanding these reasons is the first step in minimizing failures. A focus on proper training and preventative maintenance can help avoid the frustration of a break electric motor and enhance operational reliability.

Common Causes of Electric Motor Failures

Electric motors are crucial in many applications. However, they often fail due to common issues. One major cause is overheating. Research indicates that nearly 40% of motor failures stem from excessive heat. This can damage windings and lead to catastrophic breakdowns. Proper ventilation and regular maintenance are vital to prevent this.

Another issue is poor lubrication. Insufficient grease or oil can cause motors to seize up. Reports show that about 30% of motor failures are linked to lubrication problems. Regularly checking lubricant levels can prolong motor life. Additionally, misalignment can lead to vibration and premature wear. Almost 50% of electric motor failures come from misalignment. Using alignment tools can help ensure motors operate smoothly.

Understanding these common causes can lead to better management of electric motors. Regular inspections and proper care can mitigate risks. Addressing these issues proactively is essential for optimal performance and longevity. After all, the cost of neglect can be significant.

Top 10 Common Causes of Electric Motor Failures

Overheating: Identification and Prevention Strategies

Overheating is a common issue in electric motors. Many motors operate at temperatures between 70-90 degrees Celsius. Exceeding this range can lead to premature failure. According to industry reports, nearly 30% of motor failures are due to overheating. This can be attributed to factors like poor ventilation and overloading.

Preventive measures are vital. Ensure proper airflow around the motor. Installing cooling fans can help. Regularly cleaning dust and debris from the motor improves efficiency. This small step could increase a motor's lifespan by up to 20%.

Monitoring operating temperatures is also crucial. Infrared thermometers can identify hot spots. If a motor consistently runs above its rated temperature, it’s time to reassess the application. Sometimes, the equipment used may not be suitable. Basic adjustments can prevent significant issues later. Recognizing these signs early can save money and reduce downtime. Employing these strategies can mitigate the risk of overheating effectively.

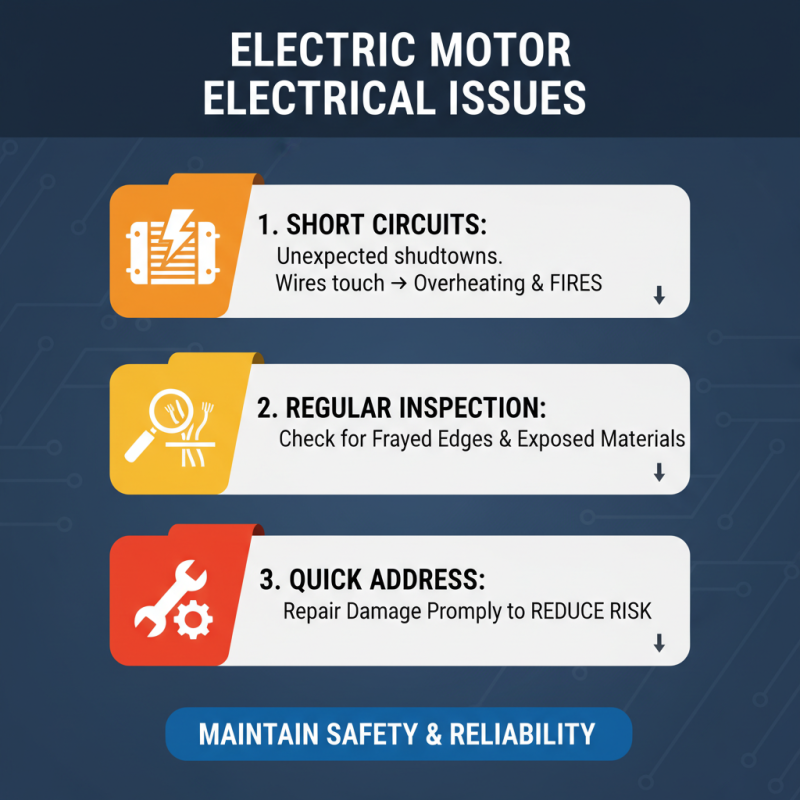

Electrical Issues: Short Circuits and Insulation Failures

Electric motors operate under various conditions, yet electrical issues remain a top troublemaker. Short circuits can unexpectedly arise, causing immediate shutdowns. When wires touch, it creates a direct path for the current. This can lead to overheating and potential fires. Inspect wiring regularly to avoid these dangers. Look for frayed edges or exposed materials. Address any damage quickly to reduce risk.

Insulation failures are another common culprit. Over time, insulation breaks down, allowing moisture and dust to penetrate. This compromises functionality and safety. A visual examination can reveal signs of wear. Using a multimeter to check resistance is also prudent. A low reading indicates insulation failure. Replacing compromised components is essential for motor longevity. When possible, choose materials designed for harsh environments to prolong life. Ignoring these issues might lead to expensive repairs or replacements later.

Mechanical Problems: Bearings, Shafts, and Alignment Issues

Electric motors are pivotal in various applications, but they often face mechanical issues. One of the most common problems arises from bearings. Bearings can wear out due to inadequate lubrication or contamination. When this happens, the motor may produce excessive noise or even complete failure. Regular checks are essential. Lack of maintenance can accelerate these failures, leading to costly repairs.

Shaft misalignment is another critical issue. Misalignment can cause uneven wear on components. It may also lead to increased vibration. This situation not only affects motor performance but can damage connected equipment over time. A simple realignment can solve this problem. Operators should be vigilant and address these issues proactively.

Over time, shaft and bearing problems can appear subtle. Small vibrations may be overlooked, causing significant downtime later. Regular inspection schedules can help identify these problems early. Technicians must develop a keen eye for detail. This can prevent minor issues from escalating into major failures.

Top 10 Reasons Why Electric Motors Break and How to Fix Them

| Reason | Symptoms | Causes | Solutions |

|---|---|---|---|

| Bearing Failure | Excessive noise, vibration | Lack of lubrication, contamination | Regular maintenance, lubrication |

| Shaft Misalignment | Unusual vibrations, overheating | Improper installation, foundation settling | Alignment checks, adjustments |

| Overheating | Burning smell, reduced performance | Overload, poor ventilation | Reduce load, improve cooling |

| Electrical Issues | Tripping breakers, intermittent operation | Short circuits, insulation failure | Inspect wiring, replace components |

| Mechanical Wear | Decrease in efficiency, increased noise | Natural wear and tear, poor maintenance | Regular inspections, timely replacements |

| Contamination | Irregular operation, visible dirt | Dust, moisture intrusion | Sealing systems, cleaning |

| Voltage Problems | Fluctuating speeds, inconsistent power | Power supply issues, bad connections | Regular electrical checks, repairs |

| Bearing Seizure | Locking up, sudden stops | Insufficient lubrication, overheating | Frequent lubrication, temperature monitoring |

| Mechanical Resonance | Vibration at certain speeds | Poor design, misalignment | Damping solutions, redesign |

| Fan Failure | Overheating, noise | Debris blockage, motor issues | Regular cleaning, fan checks |

Maintenance Practices: Best Techniques for Longevity of Electric Motors

Proper maintenance of electric motors is crucial for longevity and efficiency. According to a study by the Electric Power Research Institute, up to 40% of electric motor failures stem from improper maintenance. Routine checks can help identify wear and tear. Regularly inspecting bearings and lubrication levels significantly reduces breakdown risk.

Vibration analysis is another essential technique. It helps detect misalignment or imbalance before they escalate. In fact, a well-executed vibration analysis program can extend motor life by 50%. Additionally, ensuring clean operating environments prevents dust buildup, which can obstruct cooling. Overheating remains a common failure reason; monitoring temperature can help in early detection.

Documentation and monitoring are often overlooked. Keeping a detailed maintenance log establishes patterns and potential issues. A 2022 report showed that organizations with structured maintenance practices reported a 30% lower failure rate. Electric motors need attention and regular checking. Delaying maintenance might lead to larger issues, resulting in costly repairs and downtime.

Related Posts

-

“Evaluating the Efficiency of Electrical Fan Motors: A Comparative Analysis of Energy Consumption and Performance”

-

Empowering Your Operations: Discovering Benefits of 3ph Electric Motors for Global Sourcing

-

Rising Above Tariff Challenges: How China's Best Electric Motor Manufacturers Thrive

-

5 Reasons Why the Best Three Phase AC Motor is Essential for Your Industry Needs

-

5 Powerful Reasons to Choose the Best Three Phase AC Motor for Your Business

-

Envisioning Tomorrow: The Evolution of 3ph Electric Motors in Industry

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top