5 Effective Tips to Maximize Efficiency of Your Air Compressor for Optimal Performance

In the industrial sector, air compressors play a pivotal role in enhancing productivity and operational efficiency. According to a report by Grand View Research, the global air compressor market is expected to reach USD 41.6 billion by 2025, driven by the increasing demand for energy-efficient and reliable equipment across various industries. However, to fully harness the potential of an air compressor, proper maintenance and optimal usage are crucial. Effective management not only prolongs the lifespan of the equipment but also significantly reduces energy consumption, with studies indicating that improperly maintained systems can result in energy waste of up to 30%. Therefore, implementing strategies to maximize the efficiency of your air compressor is essential for ensuring peak performance and minimizing operating costs. In this blog, we will explore five effective tips to help you optimize your air compressor's performance.

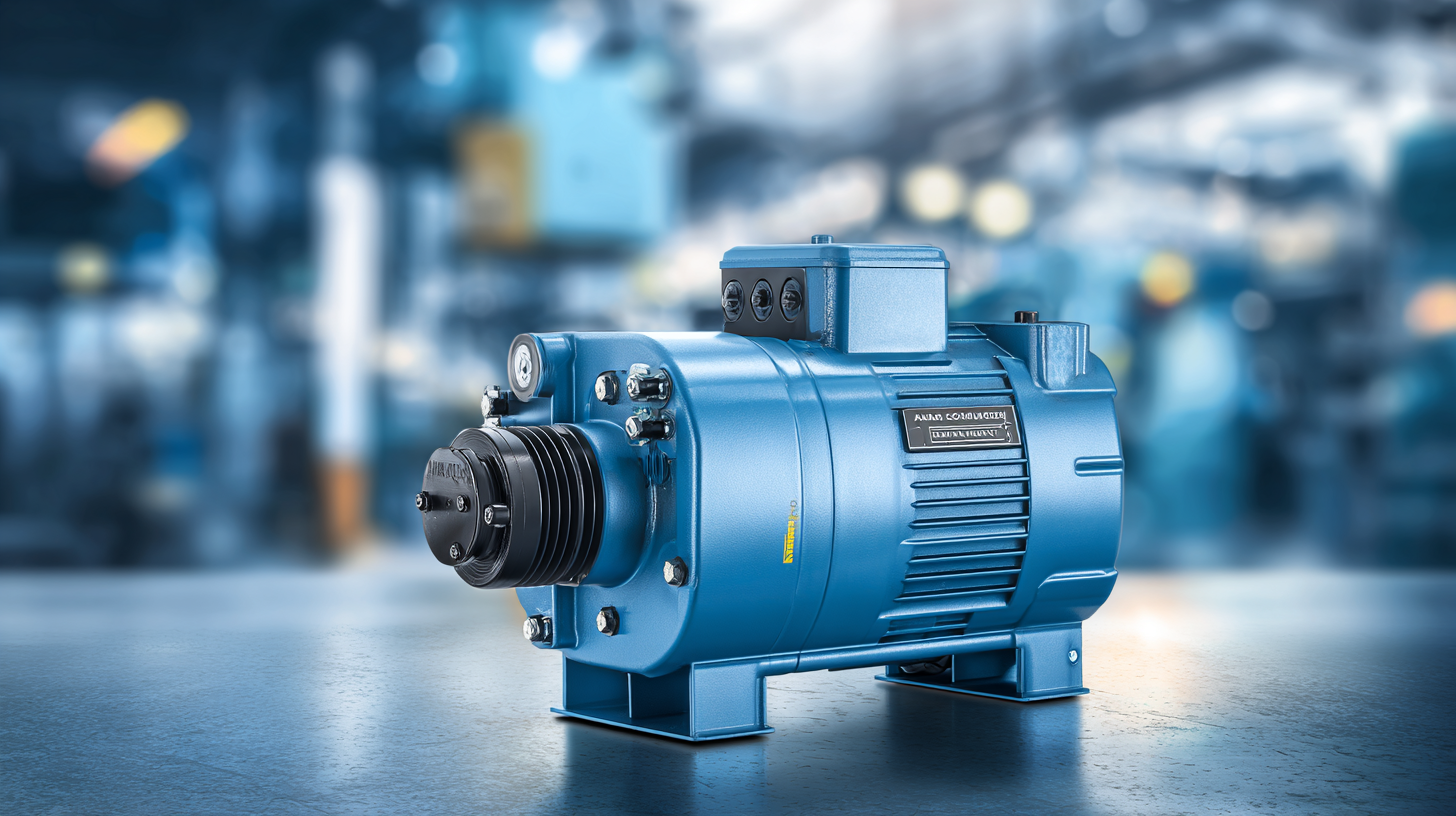

Choosing the Right Air Compressor for Your Specific Needs

When selecting an air compressor, understanding your specific needs is crucial to ensuring optimal performance. Different applications require different types of compressors. For instance, a piston compressor might be suitable for heavy-duty tasks like sandblasting, while a rotary screw compressor is often recommended for continuous operations, such as in manufacturing settings. According to a report by the International Journal of Technology and Engineering Studies, using the wrong type of compressor can lead to a decrease in efficiency by over 30%, affecting overall productivity.

Another important factor to consider is the air pressure and flow rate needed for your operations. The Compressed Air and Gas Institute (CAGI) suggests that businesses assess both the average and peak air demands of their equipment to choose a compressor with the right horsepower and CFMs (cubic feet per minute). This matching process not only enhances performance but also extends the compressor’s lifespan. A well-chosen air compressor can result in energy savings of up to 25%, making it a vital investment for any operation looking to maximize its efficiency.

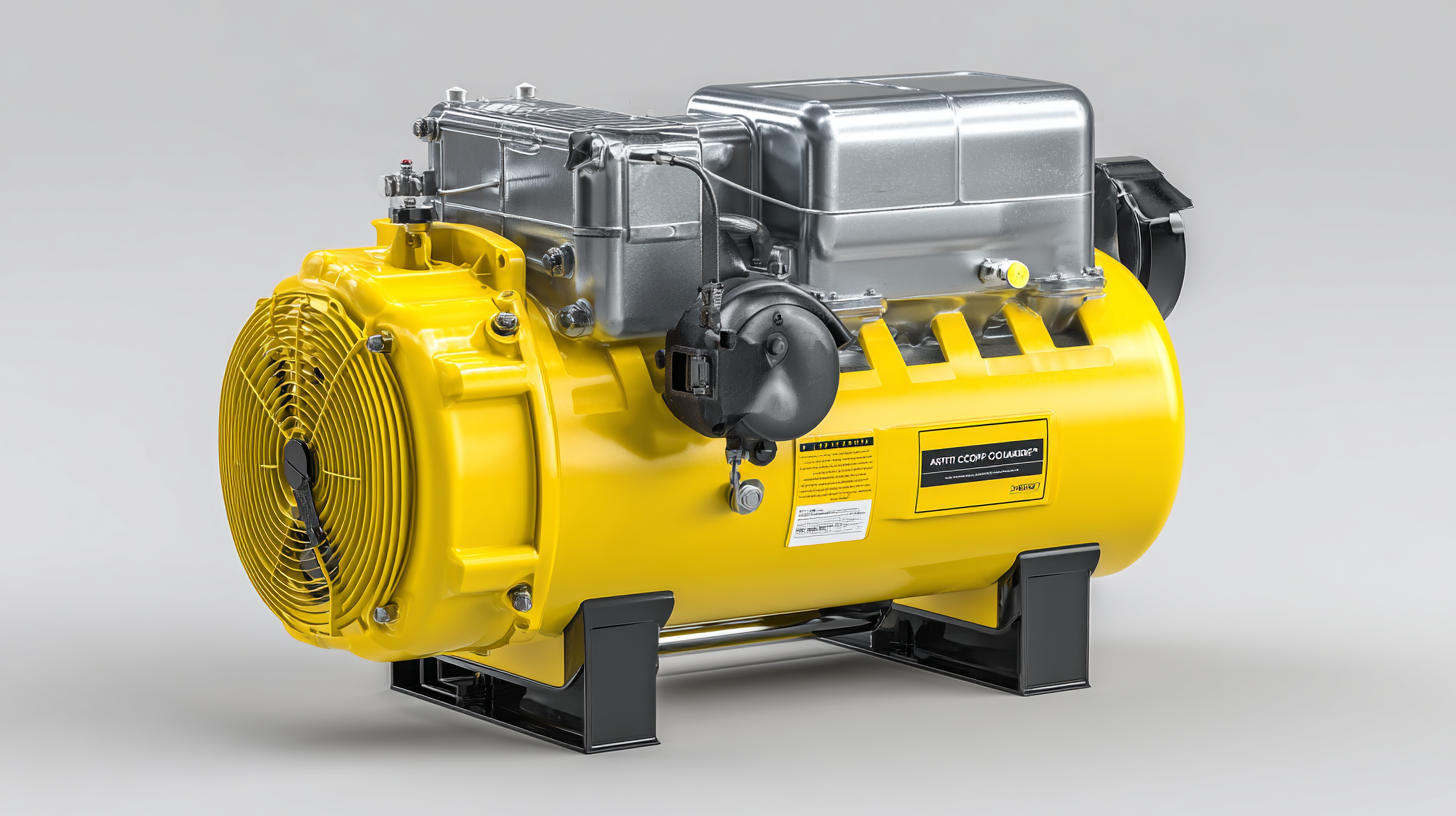

Regular Maintenance Tips to Keep Your Air Compressor Running Smoothly

Regular maintenance is crucial for keeping your air compressor operating at peak efficiency. According to the Compressed Air and Gas Institute, improper maintenance can lead to a reduction in efficiency by as much as 30%. One of the most effective strategies is to establish a routine inspection schedule. This includes checking for leaks, worn hoses, and the condition of filters. Ensuring that air intake filters are changed regularly can help maintain optimal airflow and prevent performance drops, a practice supported by findings from the U.S. Department of Energy, which indicate that a clean filter can improve energy efficiency by up to 15%.

In addition to routine inspections, lubricating moving parts is essential for minimizing friction and wear. A study conducted by the Energy Efficiency Program for Industrial Technologies revealed that proper lubrication could extend the lifespan of an air compressor by more than 50%. Replacing oil and lubricants as recommended by the manufacturer will also enhance the machine’s overall functionality and reduce unexpected downtime. Implementing these maintenance tips not only boosts the efficiency of your air compressor but also ensures a longer, more reliable service life, ultimately benefiting your operational budget and productivity.

5 Effective Tips to Maximize Efficiency of Your Air Compressor for Optimal Performance

| Tip | Description | Frequency | Benefits |

|---|---|---|---|

| Check Air Filters | Regularly inspect and clean or replace air filters to ensure proper airflow. | Monthly | Improves efficiency and prolongs compressor life. |

| Drain Water from Tank | Remove accumulated moisture from the tank to prevent corrosion and improve performance. | Weekly | Reduces risk of damage and maintains efficiency. |

| Inspect Hoses and Fittings | Check all hoses and fittings for leaks or wear and replace as necessary. | Monthly | Prevents air loss and improves system pressure. |

| Monitor Operating Pressure | Regularly check and adjust the operating pressure to the recommended setting. | Weekly | Maintains optimal performance and energy efficiency. |

| Perform Regular Lubrication | Lubricate moving parts as per manufacturer’s specifications. | Every 3 months | Reduces friction, decreases wear, and enhances efficiency. |

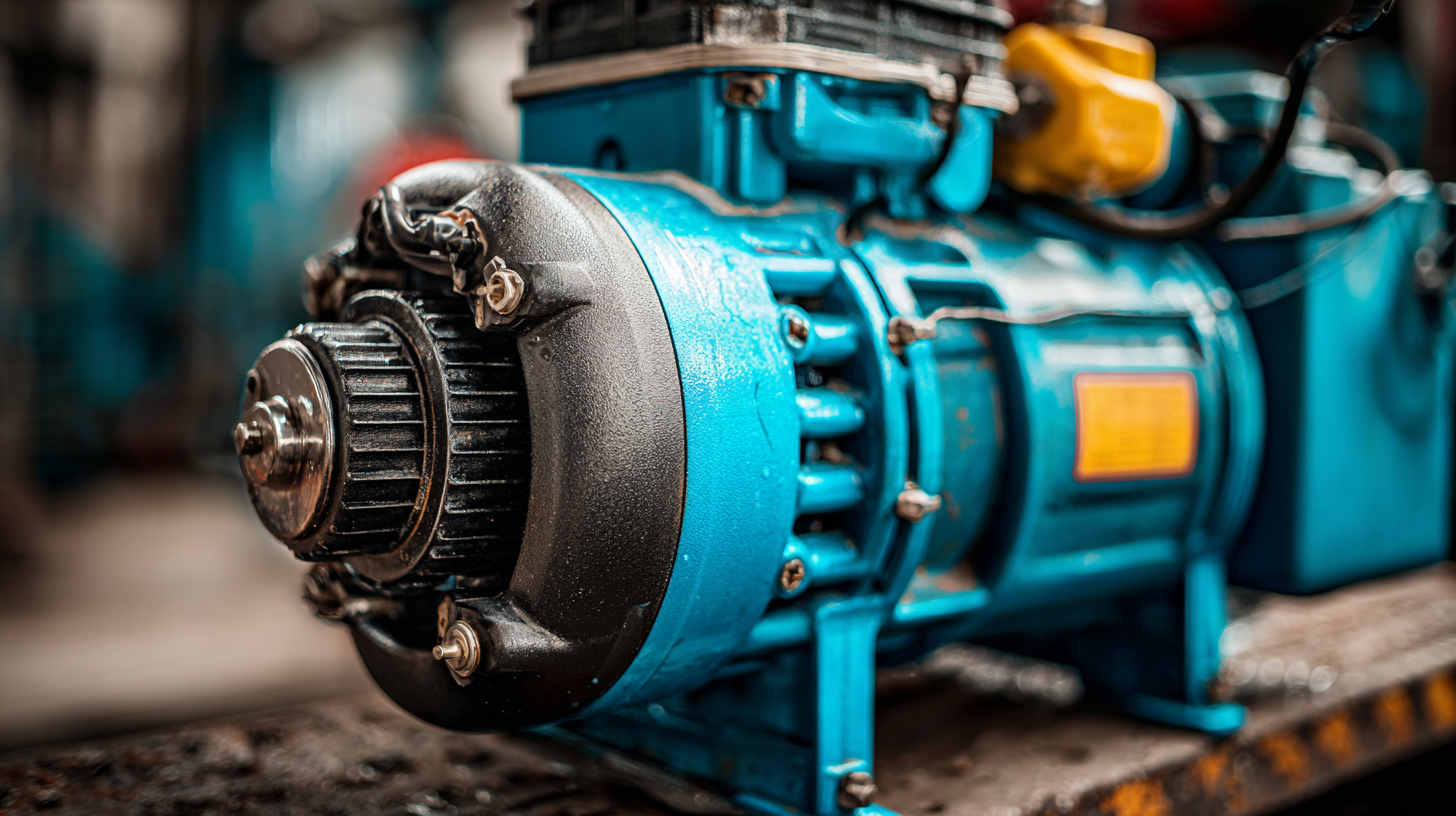

Optimizing Air Pressure Settings for Maximum Efficiency

When it comes to optimizing the performance of your air compressor, adjusting air pressure settings is a crucial step. A well-calibrated compressor not only enhances efficiency but also prolongs the lifespan of the equipment. It's essential to identify the specific pressure requirements of your tools and applications before making adjustments. Operating at the manufacturer's recommended pressure ensures you achieve optimal results without overworking the compressor, which can lead to unnecessary wear and tear.

Regular monitoring and adjustment of air pressure settings can significantly impact the overall efficiency of your compressor. Begin by using a reliable pressure gauge to check the system's output. If the pressure is too high, it can lead to excessive energy consumption and increase your operational costs. Conversely, too low of a pressure can hinder the performance of your tools. Balancing these settings is key to achieving the best performance from your air compressor while ensuring that all tools function effectively. Implementing these simple adjustments will not only help you save on energy costs but also improve the quality of the work done.

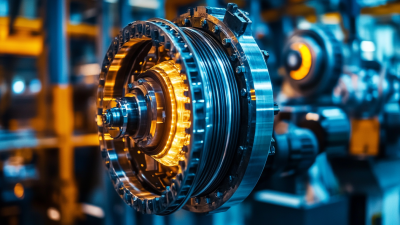

Understanding the Importance of Air Filters and Dryer Systems

Air filters and dryer systems play a crucial role in the performance and efficiency of air compressors, which are vital for various industries, from manufacturing to construction. According to a report by the Compressed Air and Gas Institute, nearly 70% of all compressed air system inefficiencies are linked to poor air quality. Contaminants such as moisture, dust, and oil can lead to equipment degradation, increased downtime, and higher operational costs. By investing in high-quality air filters, companies can remove particles as small as 0.01 micron, significantly enhancing the overall integrity of the compressed air system.

Moreover, incorporating effective dryer systems can further improve performance by eliminating moisture that could cause rusting, corrosion, and bacterial growth. A study by the U.S. Department of Energy indicates that maintaining a proper dew point with desiccant or refrigerant dryers can improve energy efficiency by up to 20%. This not only prolongs the life of the compressor and other machinery but also reduces maintenance expenses and energy consumption. By prioritizing air filters and dryer systems, businesses can ensure their operations run smoothly and efficiently, ultimately driving productivity and profitability.

Effective Storage Solutions to Enhance Air Compressor Performance

When it comes to optimizing the performance of your air compressor, effective storage solutions play a pivotal role. One of the most critical aspects is ensuring that your compressor is housed in a clean, dry environment. Moisture can lead to rust and corrosion, which compromises the overall effectiveness of the compressor. Investing in a dedicated storage area with proper ventilation and low humidity levels can significantly extend the lifespan and efficiency of your equipment.

Additionally, organizing your workspace around the air compressor can help streamline operations. Utilizing shelves and bins for tools and accessories allows for quick access, minimizing downtime when you need to make adjustments or perform maintenance. Consider using a sound-dampening enclosure as well, not only to reduce noise but also to protect the compressor from dust and debris, ensuring it maintains optimal performance. A well-structured storage system will not only enhance efficiency but also create a safer working environment.

Air Compressor Efficiency Metrics

This chart demonstrates the effectiveness of various air compressor storage solutions on overall performance and efficiency metrics, measured in cubic feet per minute (CFM) across different storage types.

Related Posts

-

Rising Above Tariffs: How China's Best Induction Motors Thrive in a Competitive Market

-

A Comprehensive Comparison of Low Speed Motors Versus High Speed Motors

-

Choosing the Right Manufacturer for the Best Asynchronous Motor to Maximize Your Investment

-

Ultimate Guide to Selecting the Best Three Phase AC Motor for Your Industrial Needs

-

Maximize Efficiency with Exceptional After Sales Support for the Best Industrial Motor

-

10 Reasons Why the Best AC Motors Outperform Competitors in Efficiency and Longevity

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top