The Ultimate Guide to Rv Gearbox: Navigating Industry Standards and Innovations for Optimal Performance

In recent years, the RV industry has witnessed significant advancements and innovations, particularly in the realm of Rv Gearbox technology. According to a report by Allied Market Research, the global RV market is projected to reach $50 billion by 2025, driven by an increasing demand for efficient and high-performing recreational vehicles. The Rv Gearbox plays a crucial role in enhancing vehicle performance, affecting everything from fuel efficiency to overall driving experience.

With industry standards continually evolving and pushing for better efficiency, durability, and ease of use, understanding the various types of RV gearboxes available is essential for enthusiasts and manufacturers alike. This guide aims to navigate through the latest advancements and standards in Rv Gearbox technology, ensuring that you are well-equipped to make informed decisions for optimal performance in your recreational vehicle.

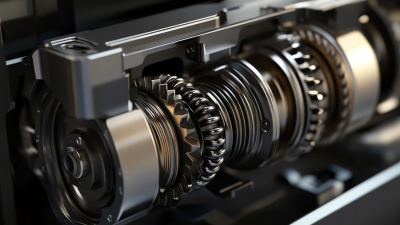

Essential Components of RV Gearbox: Understanding the Basics

When delving into the essential components of RV gearboxes, understanding the fundamentals is critical for both performance and longevity. A typical RV gearbox houses several key elements, including the input shaft, output shaft, and gear sets. According to the RV Industry Association, over 500,000 RVs are produced annually in the United States, highlighting the growing need for reliable gearbox systems that support various terrains and driving conditions.

Moreover, innovations in materials and manufacturing processes have significantly enhanced the durability and efficiency of these components. Recent reports from the Society of Automotive Engineers indicate that advanced aluminum alloys and high-strength steel are now prevalent in gearbox designs, providing better weight management and resistance to wear and tear. With these advancements, RV owners can expect improved fuel efficiency and smoother operation, particularly in models equipped with automatic transmission systems. The integration of these elements is essential for those looking to navigate the vast landscapes safely and efficiently.

The Ultimate Guide to RV Gearbox: Navigating Industry Standards and Innovations for Optimal Performance

| Component | Function | Material | Standard Compliance | Innovation |

|---|---|---|---|---|

| Gear Set | Power transmission and torque conversion | High-strength steel | ISO 9001 | Precision machining |

| Shaft | Supports and transmits rotation | Carbon fiber | ASTM D198 | Lightweight design |

| Bearings | Reduces friction between moving parts | Ceramic | ABEC 7 | Hybrid materials |

| Housing | Encases and protects internal components | Aluminum alloy | SAE J431 | Corrosion-resistant coatings |

| Seals | Prevents leakage of lubricants | Nitrile rubber | ASTM D2000 | Advanced sealing technology |

Key Industry Standards for RV Gearboxes: What You Need to Know

When it comes to RV gearboxes, understanding key industry standards is crucial for ensuring optimal performance and reliability. One of the most significant elements of a rotate vector (RV) reducer is the crankshaft bearing. This component bears the brunt of harsh working loads and operates within limited space, making its durability essential. Proper maintenance and regular inspections can prolong the lifespan of this critical part and improve overall gearbox efficiency.

When it comes to RV gearboxes, understanding key industry standards is crucial for ensuring optimal performance and reliability. One of the most significant elements of a rotate vector (RV) reducer is the crankshaft bearing. This component bears the brunt of harsh working loads and operates within limited space, making its durability essential. Proper maintenance and regular inspections can prolong the lifespan of this critical part and improve overall gearbox efficiency.

Tips: Regularly monitor the vibration characteristics of your RV gearbox, as these can provide valuable insights into its condition. Conduct periodic evaluations to identify any abnormalities early on; this proactive approach can prevent more severe issues down the line. Additionally, familiarize yourself with the latest standards in vibration testing, as they play a vital role in assessing gearbox performance at various speed ratios.

Adapting to evolving industry standards not only enhances your RV gearbox's performance but also ensures compliance with modern safety regulations. As innovations emerge, keep an eye on new technologies that can optimize your RV gear setup, thus enabling you to navigate the challenges of performance and reliability effectively.

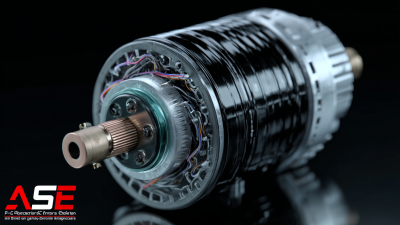

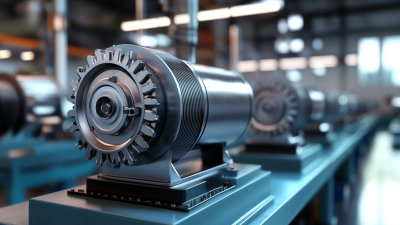

Innovative Technologies in RV Gearbox Design: A Look Ahead

The RV industry is undergoing a transformation as innovative technologies are integrated into gearbox design, enhancing performance and user experience. Companies are investing in research and development to create gear systems that are not only more efficient but also lighter and more compact. For instance, advancements in materials such as carbon fiber composites and high-strength alloys have led to gearboxes that withstand greater stress while reducing overall weight, significantly benefiting fuel efficiency and vehicle handling.

Moreover, the implementation of smart technologies is revolutionizing the way RV gearboxes operate. With the advent of sensors and real-time data analytics, manufacturers are now able to monitor performance and make adjustments on-the-fly. This allows for optimization tailored to specific driving conditions, leading to smoother shifting and improved torque distribution. As we look ahead, these innovations signify a shift towards more intelligent, responsive RV systems, promising a future where performance and efficiency are maximized, ensuring a superior experience for adventure enthusiasts on the road.

Maintenance Checklist for Optimal RV Gearbox Performance

Maintaining your RV gearbox is crucial for ensuring optimal performance and longevity. A well-functioning gearbox not only enhances your vehicle’s efficiency but also improves safety on the road. According to a recent industry report by the Recreational Vehicle Industry Association (RVIA), regular maintenance can extend the lifespan of your gearbox by up to 30%. This is why having a thorough maintenance checklist is essential for every RV owner.

Tip: Always check the gearbox oil levels and quality. Dirty or low oil can lead to premature wear and overheating. Make it a routine to inspect the oil every 3,000 miles or before any long trips. Additionally, having the oil changed annually can prevent buildup of contaminants that can compromise performance.

Another key aspect of maintenance is monitoring for any unusual noises or vibrations. A study by the National Highway Traffic Safety Administration (NHTSA) found that odd sounds often indicate underlying issues that, if addressed early, can save significant repair costs in the long run. Ensure you schedule periodic inspections with qualified technicians who can spot these issues before they escalate.

Tip: Utilize a professional service that specializes in RV gearboxes to ensure you're following industry standards. Keeping a detailed log of all maintenance activities will help you stay organized and aware of when it’s time for your next service.

Common Issues and Solutions for RV Gearbox Efficiency

When it comes to RV gearboxes, efficiency is paramount for enhancing performance and longevity. Common issues such as overheating, oil contamination, and gear misalignment can significantly hinder an RV’s drivetrain efficiency. Overheating often arises from prolonged loads or insufficient lubrication, leading to premature wear and potential failure. Regular checks of the cooling system and adhering to the manufacturer's recommended oil change intervals can mitigate this problem.

Another prevalent issue is oil contamination, which can stem from the ingress of dirt or debris. This contamination can lead to increased friction and breakdown of the gearbox components. Installing high-quality filters and routinely inspecting seals can help maintain clean oil and prolong gearbox life. Lastly, gear misalignment can cause excessive vibration and further damage. Ensuring proper installation and periodic alignment checks are vital steps toward maintaining optimal gearbox performance. By proactively addressing these common issues, RV owners can enjoy smoother rides and more reliable vehicle operation, enhancing their overall camping experience.

Related Posts

-

Exploring Innovative Rv Gearbox Options: Data-Driven Insights for Global Buyers

-

Unmatched Excellence in Chinese Manufacturing Leading the Global RV Gearbox Export Market

-

The Future of Innovation in Best 3ph Electric Motor Technology

-

7 Compelling Advantages of Choosing the Right Fire Pump for Your Needs

-

A Comprehensive Guide to Understanding AC Motors for Global Buyers

-

Top Strategies for Sourcing the Best Low Speed Motor Innovatively and Cost Effectively

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top