Challenges Faced by Global Buyers in Sourcing Aluminum Body Motors

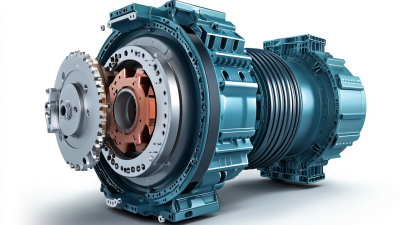

In recent years, the demand for Aluminum Body Motors has surged, driven by their lightweight characteristics and energy efficiency, becoming increasingly vital in various sectors such as automotive and aerospace. According to a report by Grand View Research, the global aluminum die casting market size is projected to reach USD 15.4 billion by 2025, partly fueled by the growing use of aluminum in manufacturing motors. However, global buyers face several challenges in sourcing these components, including fluctuating material prices, supply chain disruptions, and quality assurance issues. A report from Deloitte highlights that 60% of manufacturers in the auto sector have encountered significant supply chain challenges in the past year, emphasizing the need for robust sourcing strategies. This blog will explore these hurdles in detail, offering practical tips for navigating the complexities of sourcing Aluminum Body Motors effectively.

Understanding the Global Aluminum Body Motor Market Dynamics

In recent years, the global aluminum body motor market has gained significant attention due to its critical role in the automotive industry. With the market size projected to grow from USD 1.7 billion in 2024 to USD 2.82 billion by 2032, understanding the dynamics of this sector is essential. The surge in demand for lightweight materials, primarily driven by the need for improved fuel efficiency and reduced emissions, is reshaping the landscape. This shift presents both opportunities and challenges for global buyers navigating sourcing strategies amid fluctuating aluminum prices and supply constraints.

Moreover, as the aluminum market remains undersupplied in the coming years, buyers face the challenge of securing a reliable supply amidst rising demand fueled by electrification and innovative automotive designs. The push for sustainable vehicle production further complicates sourcing efforts, as OEMs are increasingly leaning towards sustainable materials and practices. As the automotive industry evolves, global buyers must adapt and refine their sourcing strategies to align with the shifting market dynamics of the aluminum body motor segment.

Identifying Key Challenges in Sourcing and Procurement Processes

Sourcing aluminum body motors on a global scale presents numerous challenges for buyers, particularly in the procurement process. One major obstacle is the need for

reliable suppliers who can meet quality and delivery standards. Buyers often struggle with inconsistent product quality due to varying manufacturing processes in different regions. This inconsistency can disrupt the supply chain and lead to increased costs.

Tip: To mitigate this risk, buyers should conduct thorough due diligence on potential suppliers. Establishing long-term relationships with vetted suppliers can help ensure a more stable supply of high-quality materials.

Additionally, fluctuating aluminum prices can create budgeting issues for companies. Price volatility often leads buyers to seek out multiple suppliers, complicating procurement efforts and increasing the risk of miscommunication. This can result in delays or unexpected costs.

Tip: To address pricing concerns, buyers can implement forward contracts or take advantage of hedging strategies. These approaches allow companies to lock in prices for future purchases, providing financial predictability amid market fluctuations. Integrating technology solutions, such as procurement software, can also streamline the sourcing process and enhance visibility into supplier performance.

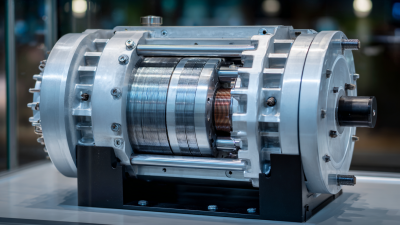

Navigating Quality Control and Compliance Issues in Manufacturing

In the quest for aluminum body motors, global buyers face significant quality control and compliance challenges that can impact the overall success of their sourcing strategies. According to a recent report by MarketsandMarkets, the global electric motor market is expected to reach $169.36 billion by 2026, signaling a booming demand for high-quality components. However, ensuring compliance with international standards such as ISO 9001 and quality benchmarks set by major automotive manufacturers remains a daunting task for many sourcing agents.

Quality control issues arise primarily due to the varying manufacturing standards across different countries. A study by Deloitte highlighted that 79% of manufacturers reported significant discrepancies in product quality when sourcing from multiple international suppliers. This inconsistency not only affects the performance of aluminum body motors but also poses risks in meeting regulatory requirements, which can lead to costly recalls and reputational damage. Global buyers need to implement rigorous quality assurance processes and choose suppliers with robust compliance frameworks to mitigate these risks and successfully navigate the complex landscape of sourcing aluminum body motors.

Analyzing Supply Chain Disruptions and Their Impact on Sourcing

The global market for aluminum body motors is experiencing significant challenges, primarily driven by supply chain disruptions. Factors such as geopolitical tensions, fluctuating raw material prices, and the ongoing aftermath of the COVID-19 pandemic have created a complex landscape for sourcing. Buyers are struggling to secure a consistent supply of aluminum, which is crucial for the production of lightweight and fuel-efficient vehicles. As manufacturing capabilities are stretched thin, lead times have increased, forcing companies to reconsider their sourcing strategies and diversify their supplier base.

Moreover, the impact of these disruptions extends beyond mere availability. Quality assurance becomes a critical concern, as buyers must navigate a landscape where some suppliers may prioritize quantity over quality to meet demand. Additionally, transportation bottlenecks and rising shipping costs further complicate the logistics of sourcing aluminum body motors. To mitigate these challenges, global buyers are increasingly investing in technology and analytics, aiming for greater visibility in the supply chain. This proactive approach not only helps in forecasting potential disruptions but also aids in building resilience against future uncertainties.

Strategies for Effective Collaboration with Aluminum Suppliers Globally

Sourcing aluminum body motors presents a unique set of challenges for global buyers, particularly when it comes to effective collaboration with suppliers. One of the foremost strategies is to establish clear communication channels early in the relationship. This involves not only discussing specifications and delivery timelines but also fostering an ongoing dialogue to address any potential issues. Regular virtual meetings, backed by collaboration tools, can help maintain a continuous flow of information and ensure that both parties are aligned on expectations.

Additionally, understanding the cultural differences and business practices of aluminum suppliers in various regions is crucial. Buyers should invest time in learning about their suppliers' operational environments and adapting their negotiation styles accordingly. This cultural sensitivity can lead to stronger partnerships and more productive interactions.

Leveraging technology, such as supply chain management software, can also facilitate smoother collaboration by providing real-time updates on production status and inventory levels, ultimately driving efficiency and reducing delays in the sourcing process.

Related Posts

-

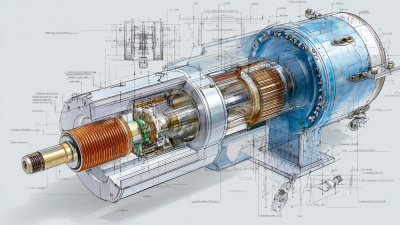

What is an Aluminum Motor and Why is it Essential for Modern Machinery

-

The Ultimate Guide to Aluminum Motors Understanding Their Benefits and Applications in Modern Industry

-

Unveiling the Specifications of the Best AC Electric Motor: A Comprehensive Technical Review

-

5 Essential Tips for Choosing the Right Gearbox Motor for Your Application

-

Rising Above Tariff Challenges: How China's Best Electric Motor Manufacturers Thrive

-

Exploring Alternative Technologies for the Best Asynchronous Motor Efficiency and Performance

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top