The Future of Innovation in Best 3ph Electric Motor Technology

In the rapidly evolving landscape of technology, the spotlight is increasingly shining on the innovations within the realm of 3ph Electric Motor systems. As industries become more energy-conscious and seek efficient alternatives, the demand for advanced electric motor technology surges. China, renowned for its manufacturing prowess, stands at the forefront of this transformation, driving advancements that not only meet domestic needs but also cater to a global market.

With its extensive export footprint, Chinese manufacturers are pushing the boundaries of performance, sustainability, and reliability in 3ph Electric Motor technology. This blog will explore the future of innovation within this sector, highlighting the emerging trends, challenges, and possibilities that lie ahead, as well as how these developments are reshaping global industrial landscapes.

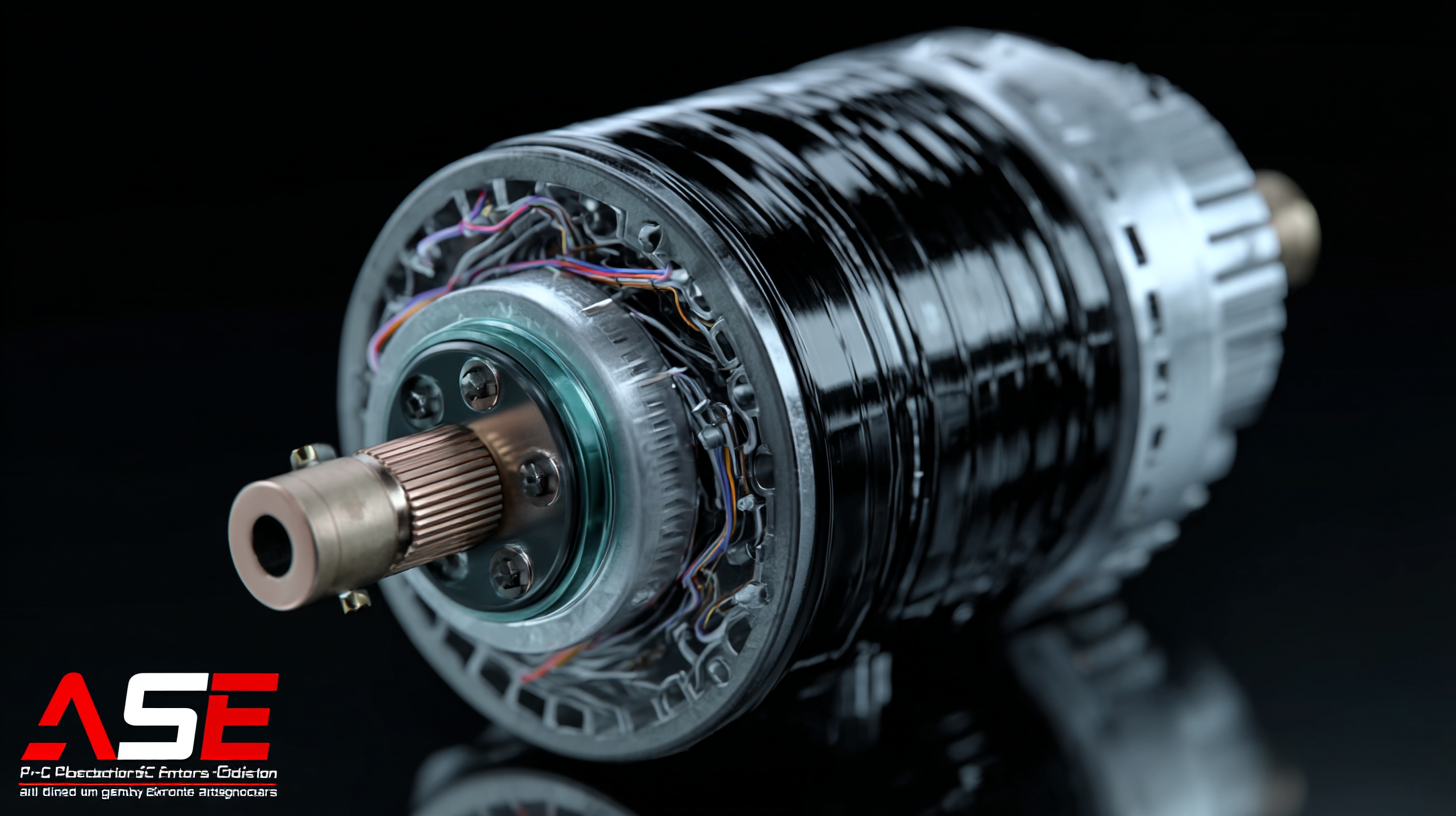

Emerging Trends in 3-Phase Electric Motor Technology for the Future

The landscape of 3-phase electric motor technology is rapidly evolving, driven by the dual forces of innovation and sustainability. One of the most significant emerging trends is the integration of smart technologies into motor systems. Advanced sensors enable real-time monitoring of motor performance, allowing for predictive maintenance and energy efficiency improvements. This data-driven approach not only extends the lifespan of electric motors but also optimizes energy consumption, making them more environmentally friendly.

Another noteworthy trend is the development of more efficient materials and designs. Manufacturers are focusing on reducing energy losses through enhanced rotor and stator designs, as well as exploring alternative materials like high-strength magnets and lightweight composites. These innovations help in producing motors that are not only more efficient but also significantly lighter, which is crucial for applications in electric vehicles and eco-friendly machinery. As these trends continue to progress, the 3-phase electric motor technology is poised to play a pivotal role in shaping a sustainable and energy-efficient future.

Key Innovations Driving Efficiency in Electric Motors

The modern landscape of electric motor technology is witnessing a remarkable evolution, primarily driven by key innovations aimed at enhancing efficiency. One of the most significant advancements is the development of high-performance materials that reduce energy losses. Using lightweight, high-conductivity materials such as silicon steel and advanced composites not only lowers the weight of the motors but also improves their efficiency significantly. These materials facilitate better heat dissipation, allowing motors to operate at higher loads without overheating, thus extending their lifespan and performance capabilities.

Additionally, the integration of smart technologies is transforming electric motor efficiency. The incorporation of sensors and IoT (Internet of Things) allows for real-time monitoring of motor performance, enabling predictive maintenance and timely interventions. This proactive approach helps in identifying inefficiencies before they lead to breakdowns, ultimately optimizing operational costs. Furthermore, advancements in motor control techniques, such as vector control and field-oriented control, enhance responsiveness and precision, ensuring that electric motors deliver maximum torque while minimizing energy consumption. These innovations collectively represent a pivotal shift towards a more sustainable and efficient future in electric motor technology.

Sustainability Practices in the Development of Electric Motors

The development of electric motors, particularly the three-phase (3ph) electric motor technology, is witnessing a significant shift towards sustainable practices. According to the International Renewable Energy Agency (IRENA), the global electric motor industry is projected to grow to $53.8 billion by 2025, with a strong emphasis on energy efficiency and reduced environmental impact. This shift is driven by stringent regulations aimed at curbing carbon emissions, as electric motors account for nearly 45% of the world's electricity consumption.

To meet these sustainability goals, manufacturers are increasingly adopting practices such as using recyclable materials and implementing advanced design methodologies that minimize waste. For instance, the use of permanent magnet motors not only enhances efficiency by up to 8% compared to conventional motors but also reduces the overall material required, thereby lowering the carbon footprint. A report by the U.S. Department of Energy indicates that enhancing motor efficiency can save up to 30% in operational costs, proving that sustainability is not just an environmental imperative but also an economic advantage for businesses. As the industry evolves, the integration of eco-friendly technologies will play a crucial role in shaping the future of electric motor development.

The Future of Innovation in Best 3ph Electric Motor Technology - Sustainability Practices in the Development of Electric Motors

| Dimension | Data Point | Percentage of Sustainable Materials Used | Energy Efficiency Rating | Average Lifecycle (Years) |

|---|---|---|---|---|

| Motor A | Model X1000 | 80% | IE4 | 20 |

| Motor B | Model Y2000 | 75% | IE5 | 25 |

| Motor C | Model Z3000 | 90% | IE3 | 30 |

Applications of 3-Phase Electric Motors in Various Industries

The application of 3-phase electric motors across various industries underscores their fundamental role in the industrial sector. Recent studies highlight the reliability and efficiency of three-phase induction motors, which are pivotal in operations ranging from manufacturing to transportation. For instance, the incorporation of artificial intelligence-driven predictive maintenance techniques can enhance the reliability of these motors by utilizing health indices to foresee operational failures. This integration holds the potential to reduce downtime and maintenance costs significantly.

Moreover, the versatility of 3-phase motors is being explored in the burgeoning electric vehicle (EV) market, where their efficiency is critical. Recent analyses indicate that electric traction systems employing 3-phase induction motors are gaining traction, with projections estimating that electric vehicles could capture 30% of the global market share by 2030. Additionally, the advancements in machine learning technologies are paving the way for improved fault detection and diagnosis in induction machines, further solidifying their presence in innovative industrial applications. As industries continue to seek reliability and efficiency, the future of 3-phase electric motors looks promising with ongoing advancements in technology.

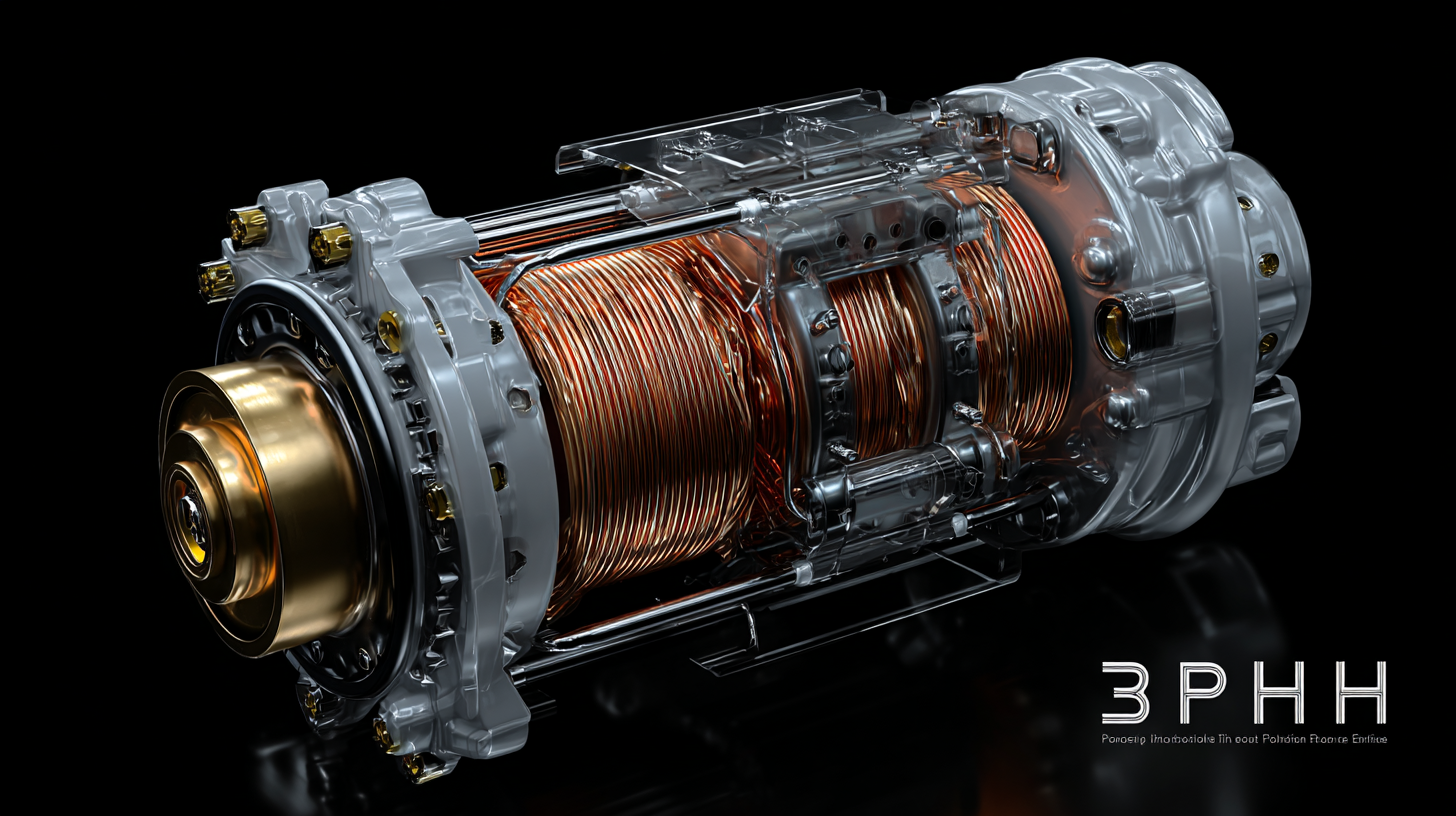

Strategies for Enhancing Performance and Longevity of Electric Motors

The advancements in electric motor technology are reshaping the future of innovation, particularly through strategies aimed at enhancing performance and longevity. Notably, the implementation of regenerative braking systems, akin to those used in hybrid vehicle technologies, demonstrates significant potential. Research indicates that integrating such systems can improve energy efficiency by as much as 30%, leading to longer operational lifespans and reduced maintenance costs for electric motors.

Moreover, advancements in materials and manufacturing processes are crucial. The introduction of advanced magnetic materials and improved winding techniques has shown to increase the efficiency of electric motors by up to 15%. This not only boosts performance but also contributes to a reduction in operational temperatures, which is essential for extending the life cycle of the motor. By focusing on these innovative strategies, the electric motor industry can ensure that future developments not only meet growing energy demands but also set new standards in efficiency and reliability.

The Future of Innovation in Best 3ph Electric Motor Technology

This chart illustrates key performance metrics for advanced 3-phase electric motors, highlighting the importance of efficiency, torque, weight, cooling time, and lifecycle. These metrics are critical for enhancing the overall performance and longevity of electric motors in future innovations.

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top