5 Essential Tips for Choosing the Right Gearbox Motor for Your Application

In today's rapidly advancing industrial landscape, selecting the right Gearbox Motor is paramount for optimizing performance and efficiency in various applications. According to industry reports, the global gearbox market is projected to reach USD 40.4 billion by 2025, with a significant contribution from the increasing demand for automation and electric drives across sectors. The right Gearbox Motor not only enhances the reliability of machinery but also substantially affects operational costs and energy consumption. With such a profound impact on both productivity and sustainability, it becomes critical for engineers and decision-makers to carefully evaluate their options.

In this blog, we present five essential tips to assist in choosing the appropriate Gearbox Motor tailored to specific application needs, ensuring optimal functionality and performance in a competitive market.

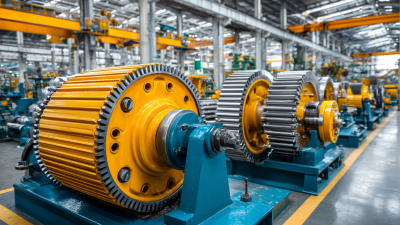

Understanding the Basics: What is a Gearbox Motor and Its Functionality

A gearbox motor is a critical component in a wide range of applications, designed to convert electrical energy into mechanical power effectively. By integrating a gearbox with a motor, the system not only enhances torque output but also allows for controlling speed more efficiently. According to a report by MarketsandMarkets, the global gear motor market is projected to reach $33.7 billion by 2027, reflecting the growing demand for high-performance motors across various industries including automotive, manufacturing, and robotics.

The functionality of a gearbox motor lies in its ability to optimize energy consumption while delivering the required performance. Gearbox motors operate by using a system of gears to reduce the speed of the motor while increasing torque. This is particularly important in applications that require precise control and reliability.

Research indicates that gearbox motors can increase efficiency by up to 30% compared to direct-drive motors, providing significant cost savings in energy and maintenance over time. Understanding these fundamentals is crucial for making informed decisions when selecting the right gearbox motor for specific applications, ensuring optimal performance and longevity.

Identifying Your Application Needs: Load Requirements and Speed Ratios

When selecting the right gearbox motor for your application, understanding your load requirements and speed ratios is crucial. The load requirements determine how much power the motor needs to manage efficiently, while the speed ratio dictates how quickly the motor can operate under various conditions. For example, if you're working with applications like diesel firefighting pumps, optimizing the transmission ratio and working load can significantly enhance performance and efficiency. Properly matching these elements ensures that the motor not only meets operational demands but also maximizes productivity.

Additionally, tools such as AVL BOOST modeling can be applied to further refine these parameters, providing a comprehensive analysis to achieve the best configuration. In industries like trucking, matching axles, ratios, and loads can lead to improved fuel efficiency through practices such as downspeeding, which minimizes engine RPMs while maximizing available torque. By thoroughly assessing your specific application needs, you can make informed decisions that align with your operational goals, resulting in a more effective and reliable motor performance.

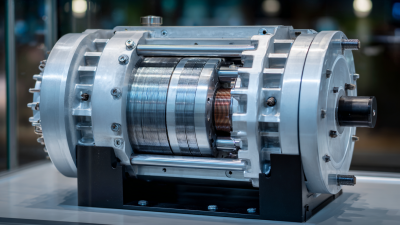

Types of Gearbox Motors: Comparing Different Designs and Configurations

When selecting a gearbox motor for your application, understanding the diverse types of gearbox motors available is crucial. Gearbox motors can vary significantly in design and configuration, affecting their performance and suitability for different tasks. For instance, planetary gearboxes are known for their compact size and high torque-to-weight ratio, making them ideal for applications requiring efficiency in limited spaces. On the other hand, helical gears provide smooth and quiet operation, which is beneficial for machinery where noise reduction is a priority.

When selecting a gearbox motor for your application, understanding the diverse types of gearbox motors available is crucial. Gearbox motors can vary significantly in design and configuration, affecting their performance and suitability for different tasks. For instance, planetary gearboxes are known for their compact size and high torque-to-weight ratio, making them ideal for applications requiring efficiency in limited spaces. On the other hand, helical gears provide smooth and quiet operation, which is beneficial for machinery where noise reduction is a priority.

Another important consideration is the application of the motor itself. For robotics, compact gearboxes that promote agility and speed are preferred, while in electric vehicles, gearbox motors designed for maximizing mechanical efficiency can lead to better energy consumption and extended range. The choice between AC and DC geared motors can also impact the overall system efficiency, with each providing distinct advantages depending on the operational requirements. By carefully evaluating these factors, you can ensure that you select the right gearbox motor that aligns with your specific demands.

Evaluating Efficiency and Performance: Key Factors to Consider

When selecting a gearbox motor for your application, it's critical to evaluate efficiency and performance to ensure optimal operation. Start by examining the motor's efficiency rating, as this will directly impact energy consumption and operational costs. Motors that boast higher efficiency ratings typically translate to lower energy bills and a reduced carbon footprint, making them a more sustainable choice over time. Additionally, consider the gear ratio that aligns with your application's specific torque and speed requirements. A well-matched gearbox motor can enhance performance, enabling smooth and stable operations across various tasks.

Another vital factor to assess is the motor's thermal performance, which reflects its ability to dissipate heat effectively during operations. Overheating can lead to decreased lifespan and increased maintenance costs. Understanding operational temperature ranges and designing your system with adequate heat management solutions will extend the motor's durability. Ensure to analyze the application's load characteristics, as varying load conditions can drastically affect performance. By meticulously evaluating these factors, you can make a well-informed decision that not only meets immediate needs but also supports long-term operational reliability.

5 Essential Tips for Choosing the Right Gearbox Motor for Your Application

This chart compares the efficiency and performance ratings of different types of gearbox motors based on essential factors like torque, speed, and power consumption.

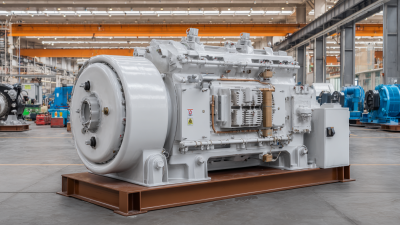

Maintenance and Durability: Ensuring Longevity in Your Gearbox Motor Selection

When selecting a gearbox motor, maintenance and durability are crucial factors that can significantly impact the overall performance and longevity of your application. According to a study by the International Society of Automation, nearly 50% of equipment failures in industrial settings can be traced back to inadequate maintenance practices. Therefore, choosing a gearbox motor that not only meets the performance requirements but also offers easy maintenance features is essential for minimizing downtime and maintenance costs.

The durability of a gearbox motor is often linked to its design and material quality. A report from the Institute of Electrical and Electronics Engineers indicates that motors with high-quality bearings and seals can last up to 40% longer than their counterparts made with standard components. It's essential to evaluate the environmental conditions in which the motor will operate—such as exposure to dust, moisture, or extreme temperatures—to select a gearbox motor specifically engineered for such challenges. By prioritizing maintenance ease and selecting parts that endure harsh conditions, you can significantly enhance the lifespan and reliability of your equipment.

5 Essential Tips for Choosing the Right Gearbox Motor for Your Application

| Parameter | Description | Importance | Tip |

|---|---|---|---|

| Load Capacity | Maximum load the motor can handle. | Critical for avoiding damage. | Choose a motor with a capacity exceeding your peak load. |

| Efficiency | Ratio of output power to input power. | Higher efficiency reduces energy costs. | Look for motors with high efficiency ratings. |

| Size and Weight | Physical dimensions and weight of the motor. | Impact on installation and space requirements. | Ensure it fits within your design constraints. |

| Durability | Longevity and resistance to wear. | Critical for reducing maintenance costs. | Select motors designed for rugged applications. |

| Type of Gearbox | Type of gear mechanism used. | Affects speed, torque, and efficiency. | Match the gearbox type to your application needs. |

Related Posts

-

Maximize Efficiency with Exceptional After Sales Support for the Best Industrial Motor

-

How to Choose the Right Gear Reducer for Optimal Efficiency: A Guide for Global Buyers

-

Exploring Alternative Technologies for the Best Asynchronous Motor Efficiency and Performance

-

Exploring the Features and Applications of the Best Asynchronous Motor in Diverse Industries

-

Solutions for Outstanding Performance in Asynchronous Motors

-

What is an Aluminum Motor and Why is it Essential for Modern Machinery

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top