Why Is an Electric Motor Essential for Modern Technology?

In today's world, the importance of the electric motor cannot be ignored. An electric motor is the heart of many technologies we rely on daily. From household appliances to electric vehicles, this device powers essential functions. Its efficiency and reliability transform electricity into motion, making it a vital component in modern innovations.

Consider your smartphone. It includes multiple electric motors enabling vibration and camera functions. Similarly, electric motors in renewable energy systems help harness wind and solar power. However, as we embrace this technology, we must consider the environmental impact of production and disposal. The growing demand for electric motors places strain on resources.

While electric motors drive progress, they also raise questions. Are we producing them sustainably? As we innovate further, our dependency on electric motors increases. Reflecting on their role challenges us to balance technology's benefits with its costs. Embracing electric motors can lead to a sustainable future, but we must tread carefully.

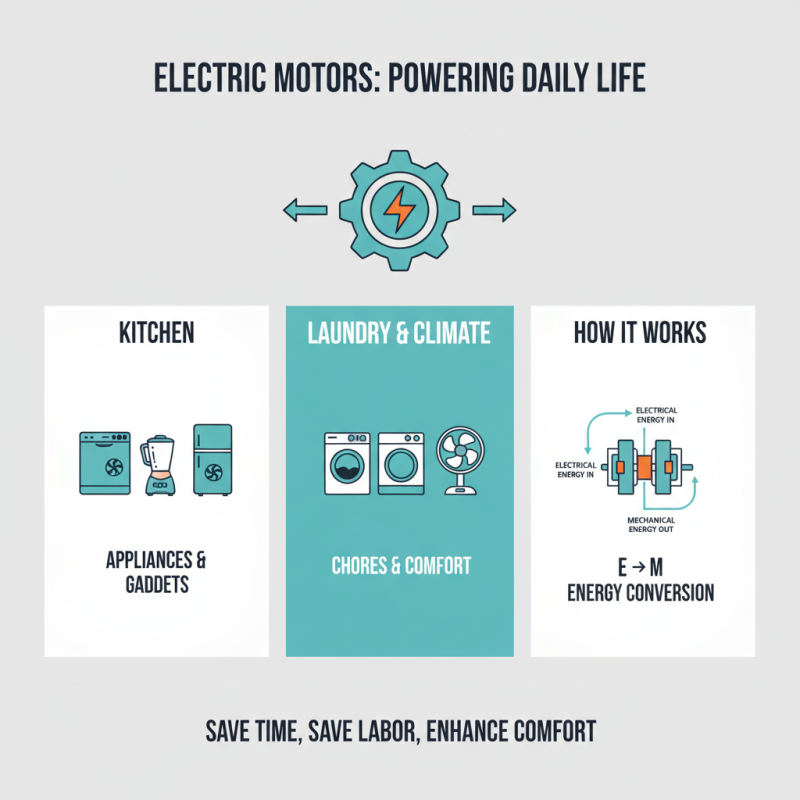

The Role of Electric Motors in Everyday Appliances

Electric motors are everywhere in our daily life. From kitchen appliances to personal gadgets, they power countless devices. A typical household relies on electric motors for dishwashers, washing machines, and fans. These motors convert electrical energy into mechanical energy, making chores easier. Imagine struggling with hand washing dishes or clothes. Motors save time and labor, enhancing our comfort.

However, dependence on electric motors has its downsides. When they break down, disruption follows. Consider a day without a washing machine; it's a hassle. Repairs can take time and money. Some people overlook their energy usage, contributing to higher bills. It's essential to reflect on our consumption habits.

The role of motors doesn't end at home. They drive tools in industries, helping to manufacturing processes. Yet, not all motors are equally efficient. Some waste energy, affecting our carbon footprint. We must question how we can use these technologies more responsibly. Balancing convenience and sustainability is crucial as we rely on electric motors more than ever.

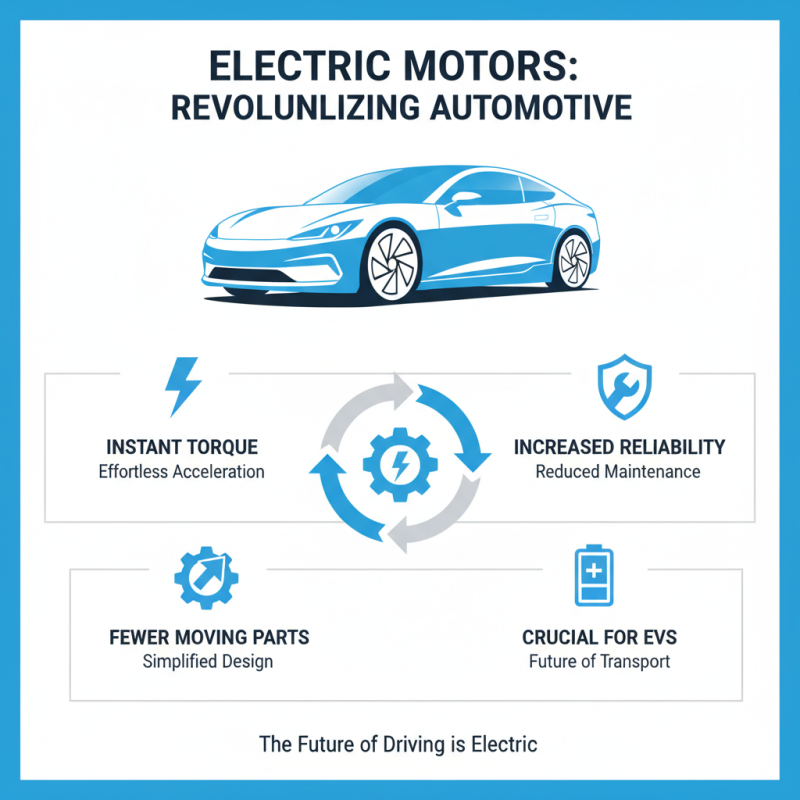

Electric Motors in Automotive Innovation and Electric Vehicles

Electric motors are transforming automotive innovation. They are crucial for electric vehicles. These motors provide instantaneous torque, allowing smooth acceleration. Unlike traditional engines, they have fewer moving parts. This simplicity leads to less maintenance and higher reliability.

In electric vehicles, energy efficiency is key. Electric motors use energy more effectively than internal combustion engines. This efficiency means longer ranges for vehicles. However, there are challenges. Battery technology must keep pace with motor development. Range anxiety still affects potential buyers. People worry about running out of power on long trips.

Moreover, charging infrastructure is still developing. Many regions lack adequate charging stations. This can deter consumers from switching to electric vehicles. Despite these setbacks, electric motors continue to pave the way for greener transportation. Their impact is undeniable, yet we must address these hurdles.

Impact of Electric Motors on Industrial Automation and Productivity

Electric motors play a crucial role in the efficiency of modern industrial processes. According to a report by the International Energy Agency, electric motors account for nearly 45% of global electricity consumption in industries. This staggering statistic highlights their significance in driving productivity. They are vital for various applications, from conveyor belts to pumps and fans.

Industries that incorporate electric motors see a remarkable boost in productivity. A study by McKinsey indicates that adopting advanced electric motor systems can increase operational efficiency by up to 25%. This improvement is crucial for companies aiming to stay competitive. Additionally, electric motors often have lower maintenance costs compared to other systems. This aspect further enhances the overall productivity.

Tips: Regularly assess your electric motor systems. Monitoring performance can identify inefficiencies early. Small changes can lead to significant savings over time. Implementing energy-efficient motors can also reduce operational costs. Evaluate your current systems and consider upgrades. A better approach may save energy and money in the long run.

Impact of Electric Motors on Industrial Automation and Productivity

Sustainable Technology: Electric Motors and Renewable Energy Integration

Electric motors play a crucial role in integrating renewable energy sources into our daily lives. Reports indicate that electric motors use less energy than traditional combustion engines. They are more efficient, converting over 90% of electrical energy into mechanical energy. This efficiency is vital as societies strive to reduce carbon emissions.

The global market for electric motors is projected to reach $120 billion by 2025. This growth highlights a shift toward sustainable technology. As more industries adopt electric motors, the demand for cleaner energy sources rises. Making better use of renewable energy, such as wind and solar, increasingly relies on effective motor technology. However, challenges remain. Some regions struggle with the integration of renewables due to outdated grid systems.

Moreover, electric motors often face obstacles related to supply chain issues. These can delay advancements, leading to inconsistencies in production. Some manufacturers grapple with sourcing sustainable materials for their products. This can hinder the full realization of electric motors as a cornerstone of sustainable technology. Industry players must address these gaps to ensure the future remains bright and efficient.

Why Is an Electric Motor Essential for Modern Technology? - Sustainable Technology: Electric Motors and Renewable Energy Integration

| Dimension | Description | Impact | Examples of Application |

|---|---|---|---|

| Energy Efficiency | Electric motors convert electrical energy into mechanical energy with minimal losses. | Reduction in energy consumption leads to lower operational costs and reduced carbon footprint. | Industrial machinery, HVAC systems, electric vehicles. |

| Renewable Energy Integration | Electric motors are essential for systems that utilize renewable energy sources. | Facilitation of clean energy transition and enhanced energy reliability. | Wind turbines, solar tracking systems, grid storage solutions. |

| Automation and Control | Electric motors enable precise control in industrial and home applications. | Increased productivity and improved operational reliability. | Robots, conveyor systems, smart home devices. |

| Maintenance and Longevity | Electric motors typically require less maintenance compared to combustion engines. | Lower long-term costs and reduced downtime for repairs. | Electric buses, home appliances, off-grid solar solutions. |

| Noise Reduction | Electric motors operate much quieter than traditional internal combustion engines. | Improved quality of life in residential areas and lower noise pollution levels. | Electric cars, household fans, and appliances. |

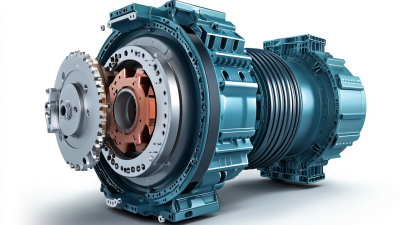

Future Trends: Advancements in Electric Motor Design and Efficiency

Electric motors are at the forefront of technology today. They power everything from electric vehicles to household appliances. However, the design and efficiency of these motors are evolving rapidly. Recent industry reports suggest that advancements in materials and manufacturing techniques will lead to a 20% increase in efficiency by 2025.

One significant trend is the development of permanent magnet motors. These motors use less energy and have a longer lifespan. The use of new magnetic materials is a game changer. Some estimates predict that they could improve performance by 30%. Yet, the sourcing of these materials poses ethical and environmental concerns. The industry must remain vigilant about sustainable practices.

Another area of focus is the integration of smart technologies. Smart motors can optimize their performance based on real-time data. This could reduce energy consumption significantly. Surprisingly, many manufacturers have yet to adopt these technologies widely. The slow transition highlights a gap between potential benefits and current practices. The industry must confront these challenges head-on to realize the full promise of electric motor advancements.

Related Posts

-

Rising Above Tariff Challenges: How China's Best Electric Motor Manufacturers Thrive

-

How to Choose the Right Electric Motor for Your Specific Needs

-

Top 10 Reasons Why Electric Motors Break and How to Fix Them?

-

Empowering Your Operations: Discovering Benefits of 3ph Electric Motors for Global Sourcing

-

The Pride of China Delivering Best Break Electric Motors to the World

-

Envisioning Tomorrow: The Evolution of 3ph Electric Motors in Industry

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top