Envisioning Tomorrow: The Evolution of 3ph Electric Motors in Industry

In the rapidly evolving landscape of industrial technology, the significance of 3ph Electric Motors cannot be overstated. According to a recent report by the International Energy Agency (IEA), electric motors account for approximately 45% of global electricity consumption in industrial applications, with three-phase (3ph) electric motors leading the way due to their efficiency and reliability. As industries strive for greater efficiency and sustainability, the continuous development and integration of 3ph electric motors is critical. These motors are not only pivotal in powering essential machinery but also play a vital role in reducing energy costs and enhancing operational performance. This blog will explore the evolution of 3ph electric motors in industry, examining the latest trends, technological innovations, and practical tips for harnessing the full potential of these indispensable devices in tomorrow's industrial settings.

The Historical Progression of 3-Phase Electric Motors in Various Industries

The evolution of 3-phase electric motors has been pivotal across various industries, driving efficiency and innovation for over a century. From the initial developments in the late 19th century, inspired by pioneering engineers, the integration of 3-phase systems has transformed manufacturing, transportation, and energy sectors. Notably, 3-phase motors are known for their ability to provide a consistent power supply, significantly enhancing operational productivity. According to industry reports, these motors can lead to energy savings of up to 30% compared to their single-phase counterparts, underscoring their vital role in driving modern industrial applications.

As industries increasingly pivot towards electric solutions, the relevance of 3-phase electric motors is further amplified in the burgeoning electric vehicle (EV) landscape. Current trends indicate that nearly two-thirds of the world's EVs are produced in regions that have embraced advanced motor technologies, highlighting the importance of 3-phase systems in achieving higher efficiencies and performance standards. For instance, as the automotive sector shifts to electric drivetrains, the demand for robust and efficient electric motors is projected to escalate, compelling manufacturers to innovate and optimize their production processes. This momentum not only reflects a historical progression but also signals a transformative future for industrial operations globally.

Key Performance Metrics: Comparing Efficiency and Output of 3-Phase Motors

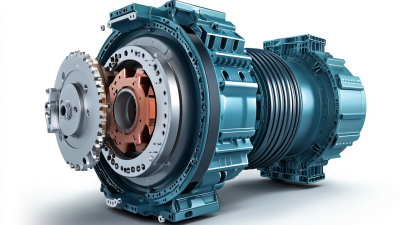

The evolution of 3-phase electric motors has significantly impacted industrial efficiency and output. These motors are widely favored for their superior performance, offering higher torque and efficiency compared to single-phase motors. When evaluating the various models, it's essential to consider key performance metrics such as power factor, efficiency ratings, and thermal management. A motor with a high efficiency rating can convert a greater portion of electrical energy into mechanical energy, ultimately reducing operational costs and increasing productivity.

Tip: When selecting a 3-phase motor for your application, ensure to analyze the load requirements and optimize the motor’s power factor. A higher power factor indicates better efficiency and can lead to lowered energy consumption.

Moreover, one must not overlook the importance of regular maintenance and monitoring of these electric motors. Implementing condition monitoring systems can help identify issues early, enhancing longevity and performance.

Tip: Opt for motors with integrated diagnostics to streamline maintenance efforts and maximize uptime, ensuring your operations run smoothly with minimal disruption.

Technological Advancements: The Shift from Conventional to Smart 3-Phase Motors

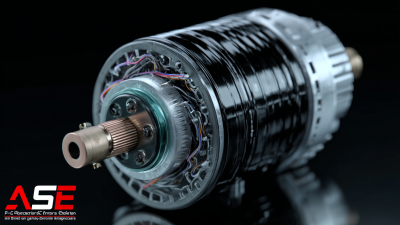

The evolution of 3-phase electric motors is marked by significant technological advancements that have transformed conventional motors into intelligent machines. Traditional 3-phase motors were primarily designed for efficiency and reliability, functioning as workhorses in manufacturing and industrial settings. However, the fast-paced demand for improved performance and energy savings has paved the way for the integration of smart technologies. These advancements include the incorporation of IoT capabilities, which allow motors to communicate with other systems, enabling real-time monitoring and predictive maintenance.

The shift from conventional to smart 3-phase motors is not just a trend; it's a necessity for modern industries. By harnessing data analytics and machine learning, smart motors can optimize their operation based on load demands, thereby enhancing overall system efficiency. Furthermore, they contribute to sustainability goals by minimizing energy consumption and reducing carbon footprints. As industries continue to embrace automation and digitization, the role of smart 3-phase motors will become increasingly critical, driving innovation and creating smarter, more resilient manufacturing ecosystems.

Envisioning Tomorrow: The Evolution of 3ph Electric Motors in Industry

Case Studies: 3-Phase Electric Motor Applications Across Different Sectors

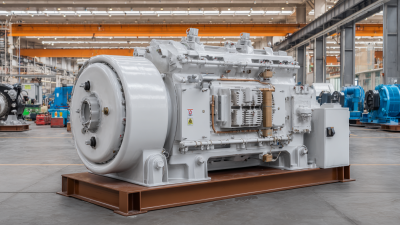

The versatility of 3-phase electric motors has made them a cornerstone in various industrial applications, revolutionizing processes across numerous sectors. In the manufacturing industry, for instance, these motors power assembly lines, conveyor systems, and robotic arms, facilitating high-speed operations while maintaining energy efficiency. Their ability to deliver consistent torque and eliminate mechanical vibrations allows for smooth scaling of production, significantly enhancing output and reducing costs.

In the HVAC sector, 3-phase motors drive compressors and fans, ensuring efficient climate control in commercial and residential buildings. Their robust design and adaptability to variable loads contribute to energy savings and sustainable practices, aligning with modern environmental standards. Additionally, in the transportation sector, these motors are increasingly utilized in electric vehicles and trains, propelling advancements in sustainable mobility solutions. By embracing the capabilities of 3-phase electric motors, industries are not only optimizing performance but also paving the way for a greener future.

Future Trends: Innovations Shaping the Next Generation of 3-Phase Electric Motors

The future of 3-phase electric motors in industry is poised for significant transformation, driven by innovative technologies and increasing demand for energy efficiency. The global market for these motors is expected to reach approximately $17.3 billion in 2024, with projections suggesting a rise to $18.7 billion by 2025 and continuing to grow at a compound annual growth rate (CAGR) through 2033. This growth reflects a broader shift in industry standards as manufacturers seek to integrate more sustainable practices in their operations.

Key trends shaping the next generation of 3-phase electric motors include advancements in materials science, which are leading to lighter and more efficient motor designs. Enhanced motor control techniques and the integration of smart technology, such as IoT connectivity, are also playing a crucial role. These innovations not only optimize performance but also enable predictive maintenance, reducing downtime and improving overall operational efficiency. As industries adapt to these emerging technologies, the drive towards modernizing motor systems will undoubtedly redefine standards across various sectors.

Related Posts

-

Empowering Your Operations: Discovering Benefits of 3ph Electric Motors for Global Sourcing

-

Rising Above Tariff Challenges: How China's Best Electric Motor Manufacturers Thrive

-

The Future of Innovation in Best 3ph Electric Motor Technology

-

The Pride of China Delivering Best Break Electric Motors to the World

-

Exploring the Features and Applications of the Best Asynchronous Motor in Diverse Industries

-

What is an Aluminum Motor and Why is it Essential for Modern Machinery

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top