Unleashing Energy Efficiency: A Comprehensive Guide to Understanding Inverter Motors

In today’s rapidly evolving industrial landscape, enhancing energy efficiency has become a critical objective for businesses striving to reduce operational costs and environmental impact. One of the most effective technologies in achieving this goal is the Inverter Motor. This comprehensive guide delves into the intricacies of inverter motors, which are designed to optimize performance and efficiency by varying the speed and torque of electric motors. By utilizing pulse width modulation and advanced control techniques, inverter motors not only decrease energy consumption but also extend equipment lifespan and enhance overall system reliability. In this “How to” guide, we will explore the working principles, benefits, and practical applications of inverter motors, empowering readers with the knowledge needed to leverage this innovative technology for better energy management and sustainability in their operations.

Understanding Inverter Motors: Principles and Applications

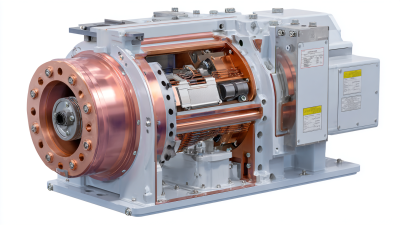

Inverter motors have emerged as a pivotal technology in enhancing energy efficiency across various applications. These motors utilize advanced electronics to convert direct current (DC) into alternating current (AC), allowing for precise control over speed and torque. Understanding their principles involves recognizing the role of components such as inverters, which adjust voltage and frequency to match the operational demands of the motor. This adaptability makes inverter motors particularly valuable in sectors such as electric vehicles (EVs) and industrial machinery, where efficiency and performance are critical.

The application of inverter motors extends into the realm of renewable energy, where their integration with systems like solar panels further enhances operational efficiency. For instance, the incorporation of maximum power point tracking (MPPT) technologies allows these motors to optimize energy use, significantly benefiting applications in electric vehicles by improving range and performance. Moreover, ongoing advancements in inverter designs, particularly in traction systems for EVs, facilitate better energy conversion and management. This not only supports the industry's shift toward cleaner energy solutions but also responds to the pressing need for sustainable power sources in the context of growing environmental concerns.

Unleashing Energy Efficiency: Understanding Inverter Motors

This bar chart illustrates the energy efficiency percentages of different types of inverter motors used in various applications. As technology advances, these motors continue to demonstrate improved energy savings, making them essential in modern engineering.

The Benefits of Energy Efficiency in Inverter Motor Systems

In recent years, the importance of energy efficiency in industrial applications has come to the forefront, particularly with inverter motor systems. According to the U.S. Department of Energy, implementing inverter duty motors can result in energy savings of up to 40% compared to standard motors. This staggering reduction not only translates to lower operational costs but also contributes significantly to overall environmental sustainability. Inverter motors allow for variable speed control, which optimizes operation based on the actual demands of the application, minimizing wasted energy.

Further supporting this shift, a report by the International Energy Agency highlights that energy-efficient motors can reduce a facility's carbon footprint by as much as 60%. Companies that have adopted inverter motor technology report not only decreased energy costs but also enhanced equipment longevity and reduced maintenance needs. The transition towards adopting inverter motors is thus an intelligent investment, as it aligns economic benefits with ecological responsibility, rendering operations more sustainable while maximizing profitability.

Unleashing Energy Efficiency: A Comprehensive Guide to Understanding Inverter Motors

| Aspect | Inverter Motors | Traditional Motors |

|---|---|---|

| Energy Efficiency | 85% - 95% | 60% - 80% |

| Control Precision | High | Low |

| Noise Level | Low | Moderate to High |

| Starting Torque | Variable | Constant |

| Lifespan | 15-20 years | 10-15 years |

| Maintenance Requirement | Low | Moderate |

Key Technologies Behind Inverter Motor Performance

Inverter motors represent a significant advancement in energy efficiency, particularly in the electric vehicle (EV) sector. The traction inverter market, driven by technologies such as Insulated Gate Bipolar Transistors (IGBTs) and Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs), is projected to see substantial growth in the coming years. According to recent industry analyses, IGBTs dominate the market due to their high efficiency and robust performance under varying temperatures and voltages. This trend indicates that manufacturers are increasingly prioritizing advanced semiconductor technologies to enhance inverter performance.

Inverter motors represent a significant advancement in energy efficiency, particularly in the electric vehicle (EV) sector. The traction inverter market, driven by technologies such as Insulated Gate Bipolar Transistors (IGBTs) and Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs), is projected to see substantial growth in the coming years. According to recent industry analyses, IGBTs dominate the market due to their high efficiency and robust performance under varying temperatures and voltages. This trend indicates that manufacturers are increasingly prioritizing advanced semiconductor technologies to enhance inverter performance.

The evolution of inverter technology is critical for optimizing battery performance and overall vehicle efficiency. Innovative solutions like GaN (Gallium Nitride) integrated circuits are being integrated with traditional IGBT technologies, facilitating the development of compact and powerful 100 kW inverters. Such improvements not only enhance the power output of electric drivetrains but also contribute to thermal management, a key concern in EV design. Reports indicate that effective thermal management will become increasingly vital from 2025 to 2035, as the integration of power electronics and advanced battery systems evolve, leading to improved vehicle efficiency and longevity.

Comparative Analysis of Inverter Motors vs. Traditional Motors

In the realm of energy efficiency, inverter motors are proving to be a revolutionary alternative to traditional motors. Unlike their conventional counterparts, which operate at a fixed speed, inverter motors utilize a variable frequency drive to adjust their speed dynamically based on the load requirements. This key feature allows inverter motors to deliver optimal performance while consuming less energy, leading to reduced operational costs and a smaller carbon footprint.

In the realm of energy efficiency, inverter motors are proving to be a revolutionary alternative to traditional motors. Unlike their conventional counterparts, which operate at a fixed speed, inverter motors utilize a variable frequency drive to adjust their speed dynamically based on the load requirements. This key feature allows inverter motors to deliver optimal performance while consuming less energy, leading to reduced operational costs and a smaller carbon footprint.

Tips: When considering a switch from traditional to inverter motors, assess the specific energy needs of your applications. This will help you calculate potential savings and determine the best inverter motor model for your situation. Moreover, ensure that your power supply can handle the requirements of inverter technology, which may differ from what traditional motors require.

Furthermore, inverter motors often come with built-in protection features, such as overload and overheat detection, enhancing their longevity. In contrast, traditional motors may require additional components for similar protections. These advanced features not only improve the reliability of businesses but also contribute to lower maintenance costs over time.

Tips: Regularly monitor and maintain your inverter motors to ensure they function at peak efficiency. Incorporating scheduled inspections and leveraging diagnostic tools can help detect any potential issues early, ultimately extending the lifespan of the equipment.

Future Trends in Inverter Motor Development and Energy Efficiency

The future trends in inverter motor development signal a transformative shift towards greater energy efficiency and innovation. With the global traction inverter market expected to surge from $11.13 billion in 2025 to $40.39 billion by 2032, a compound annual growth rate (CAGR) of 20.2% reflects the escalating demand for smarter and more efficient solutions across various industries. This rapid expansion is driven by advancements in technology, regulatory pressures to reduce carbon footprints, and a growing emphasis on sustainability.

Tips for enhancing energy efficiency in your applications include investing in high-quality inverter motors that optimize performance and minimize energy loss. Regular maintenance and monitoring of motor operations can also play a critical role in maintaining efficiency levels. Additionally, consider integrating emerging technologies like IoT for real-time data analysis and optimization, ensuring that energy consumption is continually refined.

As industries increasingly adopt these advanced systems, the focus will shift towards innovations that not only improve operational efficiency but also contribute to environmental sustainability. Companies that prioritize inverter technology are likely to gain a competitive edge, aligning with global energy efficiency goals while meeting the demands of a rapidly evolving market.

Related Posts

-

Challenges Faced by Global Buyers in Sourcing Aluminum Body Motors

-

How to Choose the Right Mining Motor for Your Operations

-

Future Trends in the Best Iron Body Motor Market Towards 2025

-

5 Essential Tips for Choosing the Right Gearbox Motor for Your Application

-

Choosing the Right Manufacturer for the Best Asynchronous Motor to Maximize Your Investment

-

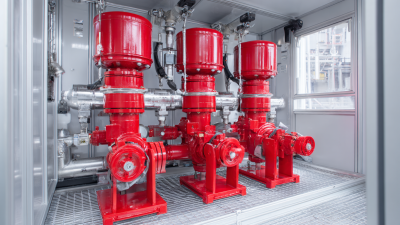

Essential Criteria for Choosing the Best Fire Pump for Your Needs

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top