2025 How to Choose the Right Mining Motor for Your Operations

Choosing the right mining motor is a critical decision that can significantly impact the efficiency and productivity of mining operations. Mining motors are essential components that power various machinery and equipment, ranging from conveyors to drilling rigs. Given the demanding nature of mining activities and the harsh environments in which they operate, selecting the appropriate motor involves careful consideration of several factors, including power requirements, durability, and energy efficiency.

As the mining industry evolves with advancements in technology and shifts in operational requirements, understanding the unique needs of your specific mining operations becomes paramount. Different types of mining—whether surface or underground—present distinct challenges that necessitate tailored solutions. This article aims to provide insights into the key considerations that should guide your selection process for mining motors, ensuring that your operations not only meet current demands but also enhance long-term sustainability and performance.

With the right mining motor, organizations can optimize their workflows, reduce downtime, and increase overall productivity, all while maintaining safety and compliance standards. By diving into the fundamental criteria for selecting mining motors, companies can make informed decisions that pave the way for successful mining operations in 2025 and beyond.

Understanding Different Types of Mining Motors Available Today

When selecting the right mining motor for your operations, it is essential to understand the various types of motors available today. Electric motors are the most commonly used in mining applications due to their efficiency and reliability. They come in various configurations, including squirrel cage, wound rotor, and permanent magnet motors. The choice among these often depends on the specific requirements of the operation, such as load characteristics, starting conditions, and environmental factors. Squirrel cage motors are favored for their simplicity and robustness, while wound rotor motors are ideal for applications requiring high starting torque.

In addition to electric motors, hydraulic and pneumatic motors are also utilized in mining operations. Hydraulic motors are often employed in situations where high torque and compact design are crucial. They can function effectively in harsh environments, making them suitable for various mining applications. On the other hand, pneumatic motors, powered by compressed air, are particularly useful in underground operations where electrical sources may be less accessible. Understanding the advantages and limitations of each type can substantially impact operational efficiency and equipment longevity, ultimately leading to a more productive mining process.

2025 Mining Motors Performance Comparison

Key Specifications to Consider When Selecting Mining Motors

Selecting the right mining motor for your operations requires a deep understanding of key specifications that directly impact performance and reliability. First, consider the motor's power rating, which should match the requirements of your machinery while providing enough headroom for operational demands. Another crucial specification is the efficiency rating; motors that operate with higher efficiency levels can significantly reduce energy costs and improve overall operational productivity.

Additionally, the environmental conditions where the motor will operate must be assessed. This includes the temperature range, moisture levels, and potential exposure to dust and chemicals. Choosing a motor with appropriate protection ratings, such as IP ratings for dust and water resistance, is essential to ensure longevity and minimize maintenance interventions.

Tips: Always consult with your engineering team to determine the exact requirements based on the application and site conditions. It is also beneficial to review the total cost of ownership, including maintenance and expected lifespan, to make an informed decision. Understanding these specifications will empower you to select a mining motor that enhances your operational efficiency and reliability.

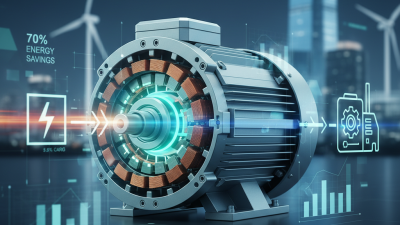

Evaluating Performance and Efficiency of Mining Motors

When choosing the right mining motor for operations, evaluating performance and efficiency is paramount. Performance is determined by various factors such as torque, horsepower, and operational speed. Understanding the specific requirements of the mining environment is essential. For instance, motors need to handle the rigors of heavy loads and harsh conditions while maintaining reliability. Assessing the duty cycle and load conditions in which the motor will operate can provide insights into the necessary performance specifications, ensuring the chosen motor can sustain peak demands without compromising longevity.

Efficiency plays a critical role in minimizing operational costs and maximizing productivity. An efficient motor will convert electrical energy into mechanical power with minimal losses, which is especially important in energy-intensive mining operations. It is essential to consider the motor's efficiency ratings and choose designs that comply with modern efficiency standards. Features such as optimized winding configurations and advanced cooling systems can significantly impact overall efficiency. Additionally, the motor's ability to operate within an optimal temperature range can help reduce failures and maintenance needs, further enhancing its performance and reliability in demanding mining applications.

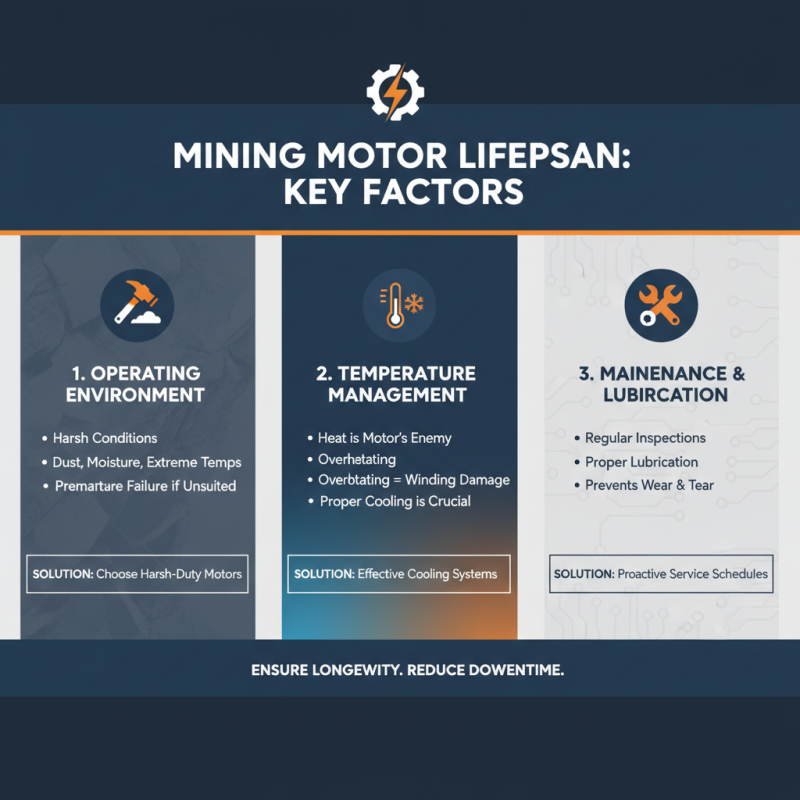

Factors Influencing the Lifespan of Mining Motors

When selecting the right mining motor for operations, understanding the factors influencing the lifespan of these motors is crucial. One primary factor is the operating environment. Mining environments are often harsh, with exposure to dust, moisture, and extreme temperatures. Motors that are not suited to withstand these conditions may fail prematurely. Therefore, it's essential to choose a motor specifically designed or rated for such harsh conditions to ensure longevity.

Another significant aspect is the maintenance schedule. Regular maintenance can dramatically extend the life of a mining motor. This includes routine inspections to identify wear and tear, timely lubrication, and immediate attention to any observed irregularities. Motors that are maintained according to the manufacturer's guidelines will generally have better performance and a longer useful life, reducing unexpected downtimes and replacement costs.

Additionally, the choice of materials used in the motor's construction plays a vital role in its durability. Motors made from high-quality, resistant materials can better handle operational stresses and minimize the risk of failure. By prioritizing these factors—operating conditions, maintenance practices, and construction materials—mining operations can significantly enhance the reliability and lifespan of their motors.

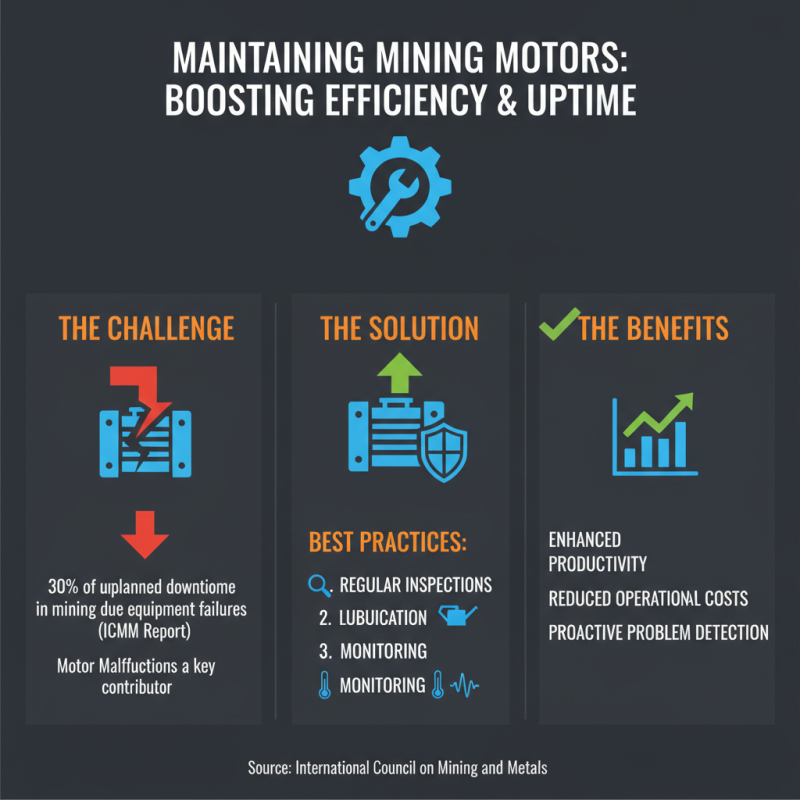

Best Practices for Maintaining Mining Motors in Operations

Maintaining mining motors is crucial for ensuring operational efficiency and minimizing downtime in mining operations. According to a report by the International Council on Mining and Metals, approximately 30% of unplanned downtime in mining operations can be attributed to equipment failures, including motor malfunctions. Thus, implementing best practices for motor maintenance can significantly enhance productivity and reduce operational costs. Regular inspections, lubrication, and monitoring of thermal and vibration levels are essential preventive measures that help in identifying potential issues before they lead to major failures.

Furthermore, establishing a predictive maintenance program using advanced technologies such as IoT sensors and data analytics can lead to significant improvements in equipment reliability. A study by the Mining Industry Technical Advisory Board indicates that predictive maintenance can reduce maintenance costs by up to 25% and extend the life of equipment by 20-30%. By leveraging these technologies, mining companies can monitor the health of their motors in real-time and make informed decisions regarding maintenance schedules. This proactive approach not only optimizes the performance of mining motors but also supports sustainable mining practices by reducing resource waste.

Related Posts

-

How to Choose the Right Mining Motor for Your Operations

-

Crafting Excellence with Chinese Manufacturing Bringing the Best Mining Motor to the Global Market

-

Solutions for Outstanding Performance in Asynchronous Motors

-

How to Choose the Right Induction Motor for Your Industrial Applications

-

How to Choose the Right RV Gearbox for Your Vehicle Performance

-

7 Compelling Reasons to Choose a Break Electric Motor for Your Machinery Needs

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top