How to Choose the Right Induction Motor for Your Industrial Applications

In the fast-evolving landscape of industrial applications, selecting the right induction motor is crucial for optimizing performance and energy efficiency. According to a recent report by the International Energy Agency, electric motors account for approximately 70% of industrial energy consumption globally, highlighting the importance of choosing an appropriate motor to reduce operational costs and enhance productivity. Induction motors, known for their reliability and durability, are among the most widely used types of motors in various sectors, including manufacturing, oil and gas, and mining.

As industries face increasing pressure to adopt sustainable practices, the demand for energy-efficient induction motors is on the rise. The latest industry projections indicate that the induction motor market is expected to grow at a CAGR of 5.5% from 2021 to 2028, driven by advancements in technology and the growing focus on reducing carbon footprints. When selecting an induction motor, factors such as load requirements, efficiency ratings, and application-specific features must be meticulously evaluated to ensure alignment with operational goals. Understanding these elements can significantly impact the overall effectiveness and sustainability of industrial operations.

Key Factors in Selecting the Ideal Induction Motor for Your Industry Needs

When selecting the ideal induction motor for industrial applications, several key factors must be considered to ensure optimal performance and efficiency. The first aspect is the power requirements of the specific application. Understanding the load characteristics, including starting torque and operational speed, is crucial for determining the appropriate motor size and type. Additionally, factors like working environment, including temperature and humidity, should influence your choice, as certain motors are designed for harsh conditions while others excel in controlled settings.

Another significant factor is the motor's efficiency rating. High-efficiency motors not only consume less energy but also reduce operational costs over time. It's essential to evaluate the motor's energy efficiency class based on the anticipated duty cycle and usage patterns. Furthermore, considering compatibility with existing systems and the availability of spare parts can enhance maintenance efficiency and minimize downtime. By carefully evaluating these factors, businesses can choose an induction motor that aligns with their specific industrial needs, ensuring reliability and longevity in operation.

How to Choose the Right Induction Motor for Your Industrial Applications

| Key Factors | Considerations | Typical Applications |

|---|---|---|

| Power Rating | Determine required horsepower based on load demands. | Pumps, Fans, Compressors |

| Efficiency | Look for high efficiency to minimize operational costs. | Conveyor Systems, Heating Systems |

| Environment | Assess the operating environment (temperature, humidity, dust). | Industrial Plants, Outdoor Installations |

| Starting Method | Select starting method based on application and load characteristics. | Cranes, Hoists |

| Speed Control | Determine if variable speed is needed for process control. | Textile Machinery, Industrial Mixers |

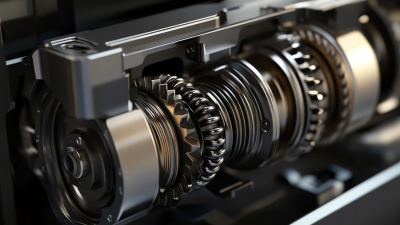

Understanding Different Types of Induction Motors and Their Applications

When selecting the right induction motor for industrial applications, understanding the different types is crucial. Induction motors are widely used across various sectors due to their efficiency and reliability. Among these, the most common types are single-phase and three-phase induction motors. Single-phase motors are typically utilized in low-power applications, such as household appliances, while three-phase motors are preferred for industrial settings due to their superior performance and ability to handle higher loads. The choice between these motors depends on the specific requirements of the application, such as power needs, efficiency, and installation constraints.

Another significant classification of induction motors includes standard and high-speed solid-rotor machines. Solid-rotor induction machines have recently gained traction due to their robustness and reliability, making them suitable for harsh industrial environments. They offer distinct advantages in terms of thermal management and longevity. Furthermore, advances such as variable frequency drives (VFDs) allow for better control of motor speed and torque, enabling enhanced efficiency in operations. Understanding these different types and their respective applications will help in making an informed decision that aligns with operational goals and efficiency requirements.

The Role of Efficiency Ratings in Choosing an Induction Motor

When selecting an induction motor for industrial applications, efficiency ratings play a crucial role in determining overall performance and cost-effectiveness. According to the U.S. Department of Energy, motors are responsible for approximately 65% of the electricity consumed in industrial facilities, making energy efficiency a vital consideration. The efficiency of an induction motor can significantly impact operating costs over its lifetime, and the adoption of high-efficiency motors can lead to energy savings of up to 8% compared to standard models.

Moreover, the efficiency rating typically categorized under NEMA (National Electrical Manufacturers Association) classifications, such as NEMA Premium® motors, allows businesses to make informed decisions. Data from the Electric Power Research Institute (EPRI) indicates that investing in high-efficiency motors can yield a return on investment (ROI) within 1 to 3 years, depending on operating hours and energy costs. Therefore, understanding and prioritizing efficiency ratings not only enhances performance but also contributes significantly to sustainability efforts and long-term savings for industrial operations.

How to Determine the Right Power Rating for Your Induction Motor

Choosing the correct power rating for an induction motor is crucial for ensuring optimal performance in industrial applications. To begin, it's essential to assess the specific requirements of your application, including load type, operational frequency, and the duty cycle of the motor. Understanding the nature of the load—whether it is constant or variable—and its power requirements will significantly influence the power rating needed. For instance, a motor intended for a consistent load, such as a conveyor belt, may require a different power rating than one utilized for startup applications like pumps.

Additionally, consider the starting and running conditions of the motor. The power rating should accommodate the starting torque needed to overcome inertia and ensure the motor can handle peak loads without stalling. When determining the right power rating, it's advisable to consult motor efficiency ratings and factor in potential future demands, such as expansion or increased production rates. By carefully analyzing these elements, one can select an induction motor that not only meets current requirements but also provides reliable and efficient operation in the long term.

Essential Maintenance Tips to Extend the Life of Your Induction Motor

When it comes to extending the life of your induction motor in industrial applications, regular maintenance is crucial. High temperatures and demanding environments can accelerate wear and tear, making it essential to stay proactive. One effective tip is to ensure that the motor is properly ventilated. Overheating can lead to premature failure, so maintaining a clean environment and allowing adequate air circulation is vital.

Another important maintenance tip is to routinely inspect and tighten all electrical connections. Loose connections can cause heating issues and lead to short circuits. Additionally, consider implementing vibration analysis as part of your routine checks. This technique helps detect early signs of imbalance or wear in bearings, allowing you to address issues before they escalate. Regularly checking and replacing worn-out parts, such as bearings or seals, can also significantly enhance the motor's longevity, ensuring consistent performance in demanding industrial settings.

Performance Metrics of Induction Motors in Industrial Applications

This chart represents key performance metrics of induction motors essential for industrial applications. The metrics include efficiency, load factor, maintenance frequency, temperature rise, vibration level, and noise level. Understanding these metrics can help in choosing the right induction motor and implementing effective maintenance strategies.

Related Posts

-

Solutions for Outstanding Performance in Asynchronous Motors

-

Exploring Best Break Motor Applications in Industry with a Step by Step Guide

-

7 Compelling Advantages of Choosing the Right Fire Pump for Your Needs

-

Discover Premium Low Speed Motors Directly from China's Leading Manufacturing Factory

-

Exploring Innovative Rv Gearbox Options: Data-Driven Insights for Global Buyers

-

10 Advantages of Choosing the Best Break Motor for Your Next Project

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top