How to Choose the Right Gearbox Motor for Your Application

In today's industrial landscape, selecting the appropriate Gearbox Motor is crucial for optimizing performance and efficiency across various applications. A recent report by MarketsandMarkets indicates that the global gearbox market is projected to reach $38.6 billion by 2025, driven by the increasing demand for energy-efficient motors and automation technology. This underscores the importance of making informed choices when it comes to gearbox motors, as they play a pivotal role in converting speed and torque to meet specific operational requirements.

Whether in manufacturing, transportation, or robotics, understanding how to choose the right gearbox motor can significantly impact productivity and reduce operational costs. In this blog, we will explore essential factors to consider, enabling you to make the best decisions tailored to your unique application needs.

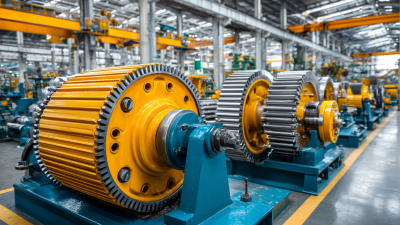

Understanding the Types of Gearbox Motors Available for Industrial Applications

When selecting a gearbox motor for industrial applications, it’s essential to understand the various types available to ensure optimal performance. The most common types include helical, bevel, and worm gear motors, each suited for specific operational needs. Helical gear motors offer high efficiency and durability, making them ideal for continuous operations. Bevel gear motors provide compact designs for applications requiring right-angle drives, while worm gear motors excel in applications needing high torque at low speeds.

Tips for choosing the right gearbox motor include assessing the required torque and speed for your application — these parameters are critical in determining the best motor type. Additionally, consider the operating environment; factors such as temperature, humidity, and potential exposure to corrosive elements can significantly affect performance and longevity. Lastly, think about the compatibility with existing equipment to ensure seamless integration and functionality.

Understanding these variables will help streamline the selection process, ensuring that the gearbox motor chosen enhances efficiency and meets productivity goals. Careful consideration of the various gearbox motor types and their specific advantages will set a solid foundation for effective industrial operations.

Key Factors to Consider When Selecting a Gearbox Motor for Your Needs

When selecting a gearbox motor for your application, several key factors must be taken into account to ensure optimal performance and efficiency. The application requirements, such as load capacity and speed, should dictate the type of gearbox motor you choose. According to a recent industry report by Research and Markets, the global gear motor market is projected to reach $34 billion by 2026, driven by increasing demand for automation across various sectors. With the rise in automation, it becomes crucial to match the motor's specifications with operational demands, ensuring longevity and reliability in performance.

Another critical factor is the size and weight limitations of your application. Gearbox motors come in various sizes, and selecting a motor that fits your spatial constraints while providing adequate torque is essential. A study by Allied Market Research highlighted that compact gearbox motors are gaining popularity, particularly in robotics and mobile equipment, where space is at a premium. Additionally, consider the efficiency ratings of the motor. Higher efficiency not only reduces energy costs but also minimizes heat production, contributing to the overall reliability of your system. By carefully evaluating these key factors, you can make a well-informed decision that aligns with your specific requirements.

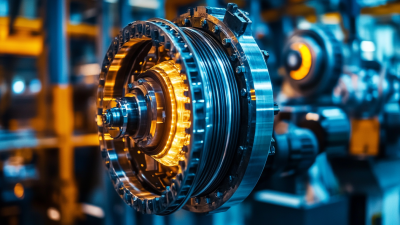

Analyzing Torque, Speed, and Efficiency Ratings in Gearbox Motors

When selecting the right gearbox motor for your application, understanding the interplay of torque, speed, and efficiency ratings is essential. Torque, the rotational force produced by the motor, determines how much load the gearbox can handle. It's crucial to match the motor's torque output with the required torque of your application to ensure that it can perform efficiently under load. If the torque is insufficient, the system may underperform or even stall, while excessive torque can lead to overheating and mechanical failure.

Speed is another critical factor, as it relates to the number of revolutions per minute (RPM) the motor can achieve. Different applications require different speed ranges; for instance, conveyor systems may need consistent, moderate speeds, whereas robotics might require high-speed operations. Additionally, when evaluating efficiency ratings, consider how much energy the motor consumes during operation compared to the output. High-efficiency motors save energy costs and reduce heat generation, extending the lifespan of your equipment. By carefully analyzing these elements, you can make a more informed decision and ensure optimal performance for your specific needs.

The Role of Application Environment in Gearbox Motor Selection

When selecting a gearbox motor, one of the most critical factors to consider is the application environment. The operational setting can significantly affect the performance and longevity of the motor. For instance, if the application involves exposure to extreme temperatures, humidity, or corrosive substances, it's essential to choose materials and designs that can withstand these conditions. Motors intended for outdoor use may need additional protective features, such as weatherproof enclosures or corrosion-resistant coatings, to ensure durability and reliability.

Moreover, the environment can influence the motor's power requirements and torque output. Applications in rugged, industrial settings may demand motors that can handle heavy loads and provide consistent performance under stress. Conversely, for clean and controlled environments, precision motors with finer outputs may be more appropriate. Considering factors such as vibration levels, dust accumulation, and potential interference from electromagnetic fields can further guide your selection process, ensuring that the gearbox motor aligns perfectly with the specific requirements of your application.

How to Choose the Right Gearbox Motor for Your Application

This chart displays the performance ratings of different gearbox motors based on various application environments. The data highlights the torque and efficiency levels for each type of motor, aiding in the selection process for specific applications.

Best Practices for Maintaining Gearbox Motors to Extend Their Lifespan

Maintaining gearbox motors effectively is crucial for ensuring their longevity and operational efficiency. One of the best practices is to adopt a proactive maintenance mindset, focusing on condition-based maintenance tools that can accurately gauge the health of your assets. By monitoring the P-F curve, which highlights the progression of potential failures to functional failures, businesses can identify issues before they lead to costly breakdowns. This approach not only minimizes downtime but also aligns with modern competitive pressures by optimizing resource allocation and reducing maintenance costs.

Additionally, employing better lubrication practices is essential for prolonging gearbox motor life. Proper lubrication reduces friction and wear, directly translating to fewer breakdowns and enhanced performance. Businesses implementing enhanced lubrication strategies often find that they can significantly extend the lifespan of their machinery. Moreover, incorporating standards such as ICML 55.1 can assist organizations in refining their maintenance protocols, thus fostering a culture that prioritizes preventive care and efficiency over reactive responses to failures. This maintenance mentality ultimately leads to higher profits and operational resilience in an ever-evolving industrial landscape.

Related Posts

-

How to Choose the Right Gear Reducer for Optimal Efficiency: A Guide for Global Buyers

-

Unmatched Quality of Best Cast Iron Motors from World Leading Chinese Manufacturers

-

Discover Premium Low Speed Motors Directly from China's Leading Manufacturing Factory

-

Rising Above Tariffs: How China's Best Induction Motors Thrive in a Competitive Market

-

How to Choose the Best Three Phase Ac Motor for Your Industrial Needs

-

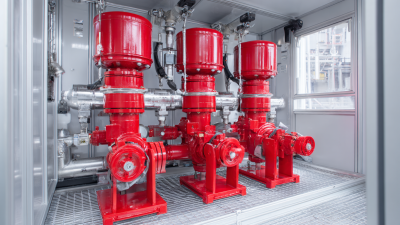

Essential Criteria for Choosing the Best Fire Pump for Your Needs

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top