How to Choose the Right Gear Reducer for Your Industrial Applications

In the realm of industrial applications, selecting the

appropriate gear reducer is crucial for ensuring optimal performance and efficiency in machinery. A gear reducer, typically used to reduce the speed of a motor while increasing torque, plays a vital role in diverse sectors, from manufacturing to robotics. However, with the myriad of options available, identifying the right gear reducer can be a daunting task. This blog will explore the top five reasons why making an informed choice in gear reducers is essential for your specific needs. By understanding the intricate balance between load requirements, speed ratios, and operational efficiency, you can enhance the functionality of your equipment and ultimately improve productivity. Whether you are upgrading existing machinery or integrating new systems, the proper gear reducer can significantly impact your operational success.

In the realm of industrial applications, selecting the

appropriate gear reducer is crucial for ensuring optimal performance and efficiency in machinery. A gear reducer, typically used to reduce the speed of a motor while increasing torque, plays a vital role in diverse sectors, from manufacturing to robotics. However, with the myriad of options available, identifying the right gear reducer can be a daunting task. This blog will explore the top five reasons why making an informed choice in gear reducers is essential for your specific needs. By understanding the intricate balance between load requirements, speed ratios, and operational efficiency, you can enhance the functionality of your equipment and ultimately improve productivity. Whether you are upgrading existing machinery or integrating new systems, the proper gear reducer can significantly impact your operational success.

Understanding Gear Reducers: Importance in Industrial Applications

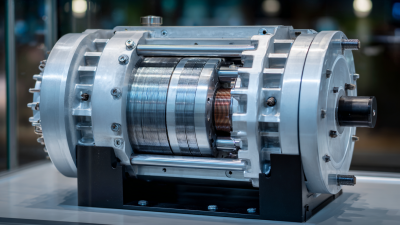

Gear reducers are crucial components in industrial applications, functioning to decrease the speed of motors while increasing torque. Their importance cannot be overstated, as they serve to optimize the performance of various machinery, ranging from conveyor systems to complex robotic arms. By converting high-speed input into manageable output, gear reducers enhance efficiency, allowing equipment to operate at the optimal levels required for specific tasks.

Understanding the various types of gear reducers available—such as planetary, worm, and helical—can significantly influence the operational efficiency of your industrial processes. Each type has its unique advantages and ideal applications, depending on factors like load requirements, space constraints, and desired output speeds. The right gear reducer not only improves the longevity of your machinery but also contributes to energy savings, minimizing operational costs in the long run. Therefore, selecting a suitable gear reducer is a fundamental step in ensuring the reliability and effectiveness of any industrial operation.

Key Specifications to Consider When Selecting Gear Reducers

When selecting a gear reducer for industrial applications, it's crucial to pay attention to several key specifications that can significantly impact performance and efficiency.

Firstly, consider the gear ratio, which determines the speed reduction and torque multiplication. A higher gear ratio means greater torque, but it may reduce speed, so always align this with your application's requirements.

Another important specification is the input and output orientation. Depending on the space constraints and machinery layout, you may need a specific mounting style, such as shaft input or flange-mounted units. Ensure that the chosen gear reducer can accommodate the overall design and installation needs of your equipment for optimal functionality.

Tips for proper selection include evaluating the operational environment. If your application involves high temperatures or exposure to chemicals, opt for gear reducers made of materials that can withstand these conditions. Additionally, always assess the manufacturer’s reputation and support services, as a reliable supplier can provide invaluable assistance in troubleshooting and maintenance.

Analyzing Load Requirements: Torque and Speed Calculations

When selecting the right gear reducer for your industrial applications, understanding load requirements is crucial. Two primary factors to consider are torque and speed. Torque determines the twisting force the reducer must provide, while speed refers to the output velocity necessary for the application. Accurate calculations of these parameters help ensure the gear reducer can handle the specific demands of your machinery.

Tips for calculating torque: Begin by identifying the load type—dynamic or static. Then, use the formula Torque = Force x Distance to ascertain the required torque based on the maximum load. Additionally, remember to factor in safety margins to account for unforeseen stresses during operation.

For speed calculations, first determine the input speed of the motor and the required output speed for your application. The gear ratio is essential here, as it defines how many times the input speed is multiplied (or divided) to achieve the desired output speed. It's advisable to operate within the recommended speed range of the gear reducer to avoid overheating and wear over time. Make sure to consult the manufacturer's specifications for optimal performance and longevity.

Material and Design Considerations for Gear Reducers

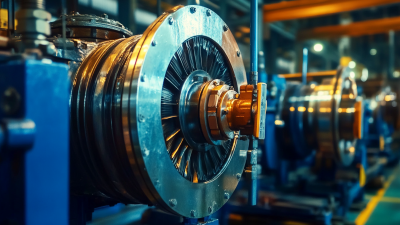

When selecting a gear reducer for industrial applications, material and design considerations are paramount. The choice of materials directly influences the durability and efficiency of the reducer. Common materials include steel, aluminum, and various polymers, each offering unique benefits. For instance, steel gear reducers are known for their strength and ability to handle high loads, while aluminum reducers are lightweight and corrosion-resistant, making them ideal for applications with environmental challenges. Understanding the application requirements will guide you in selecting the right material that balances strength, weight, and cost.

Design is equally crucial when choosing a gear reducer. The configuration of gears, such as helical, bevel, or worm, can affect performance characteristics like efficiency, noise levels, and backlash. For example, helical gears provide smoother operation and higher efficiency compared to spur gears, making them suitable for high-speed applications. Moreover, consider the mounting options and integration capabilities with existing machinery. A well-designed gear reducer will not only enhance performance but also reduce maintenance needs and downtime, ensuring a better overall operational efficiency.

How to Choose the Right Gear Reducer for Your Industrial Applications - Material and Design Considerations for Gear Reducers

| Dimension | Material | Design Consideration | Torque Capacity (Nm) | Efficiency (%) |

|---|---|---|---|---|

| Small | Aluminum Alloy | Compact Design | 50 | 90 |

| Medium | Cast Iron | High Durability | 150 | 85 |

| Large | Steel | Heavy-Duty Design | 300 | 80 |

| Extra Large | High-Strength Alloy | Modular Design | 600 | 75 |

Case Studies: Successful Gear Reducer Implementations in Industry

When selecting the right gear reducer for industrial applications, understanding successful case studies can provide invaluable insights. For instance, the recent growth reported by a leading domestic manufacturer highlights how effective gear reducer implementations can drive significant revenue and profit increases. In 2024, this company noted an 8.76% rise in revenue and a 25.42% jump in net profit, showcasing the direct correlation between innovative gear solutions and organizational success.

Case studies reveal that high-precision gear reducers, such as RV models employed in robotics, are essential for ensuring efficient operations. The strict precision requirements of these components are pivotal in enhancing the overall performance of robotic systems. Another noteworthy development is the establishment of a new factory dedicated to wind turbine gear reducers, underlining a strategic investment in R&D to meet the growing demand for reliable power generation technologies. These examples illustrate not only the critical role of gear reducers in various industries but also the strategic initiatives that propel companies to new heights.

Related Posts

-

5 Essential Tips for Choosing the Right Gearbox Motor for Your Application

-

Exploring Alternative Technologies for the Best Asynchronous Motor Efficiency and Performance

-

Unmatched Excellence in Chinese Manufacturing Leading the Global RV Gearbox Export Market

-

5 Reasons Why the Best Three Phase AC Motor is Essential for Your Industry Needs

-

The Pride of China Delivering Best Break Electric Motors to the World

-

Quality Trustworthy Exhaust Fan Motors Connect China to the World

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top