How to Choose the Right Electric Motor for Your Specific Needs

Choosing the right electric motor is a critical decision that can significantly impact the efficiency, performance, and longevity of your application. With the global electric motor market projected to reach $169.8 billion by 2026, according to a report by Fortune Business Insights, understanding the various types and specifications available is more important than ever. Electric motors are essential in a multitude of industries, from manufacturing to transportation, with up to 70% of the total electricity consumption in industrial applications attributed to motor-driven systems, as reported by the International Energy Agency. Selecting the appropriate electric motor not only enhances operational efficiency but also contributes to energy savings and reducing carbon footprints. Thus, a thorough comprehension of different motor types, their power output, efficiency ratings, and application-specific features is vital for achieving optimal results in your project.

Understanding Your Application Requirements for Electric Motors

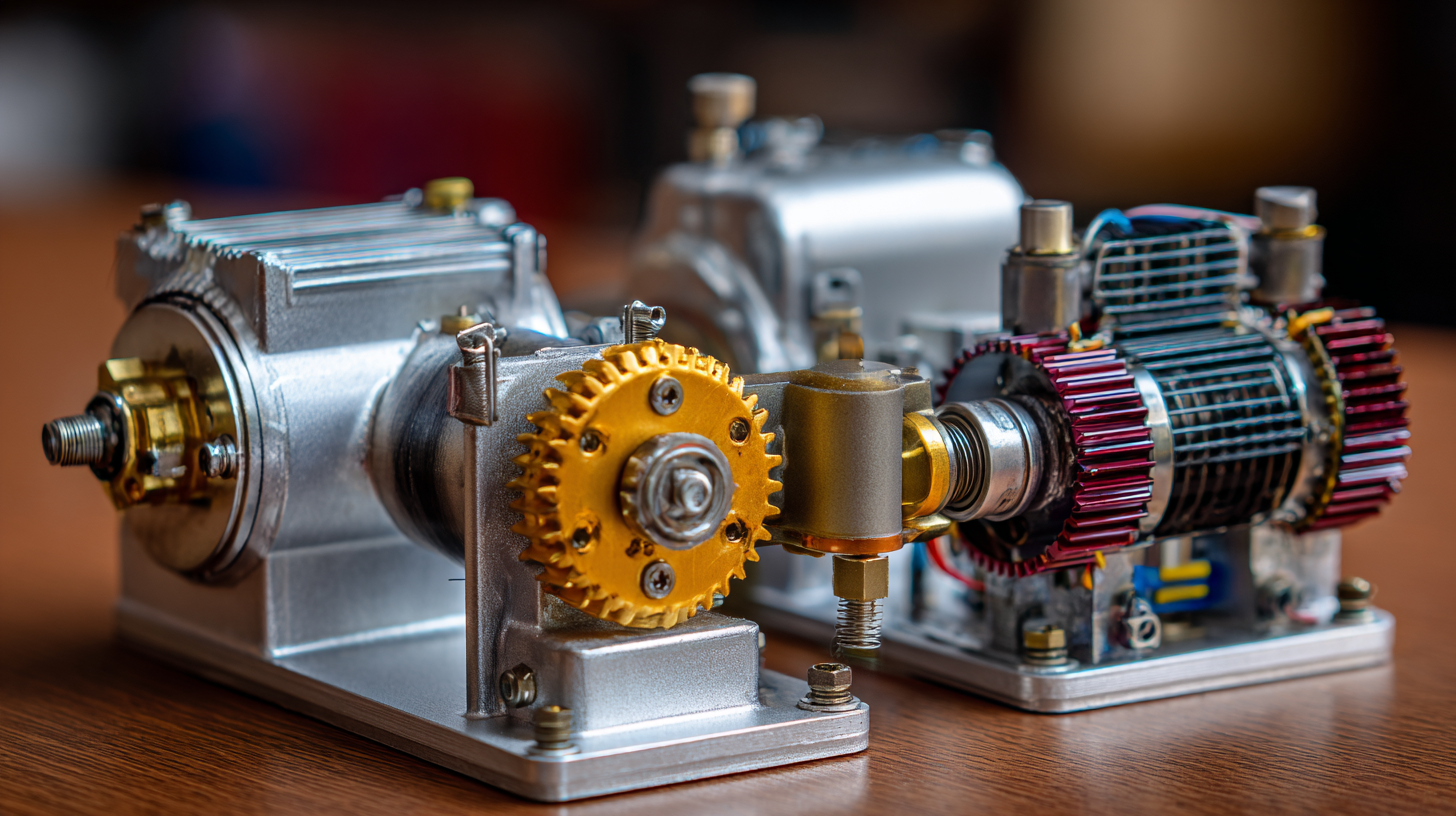

When choosing the right electric motor for specific needs, it is crucial to understand the application requirements carefully. For instance, the global electric vehicle market is expected to reach a staggering value of $145.15 billion by 2024 and continue to grow to approximately $2,581.7 billion by 2032. This rapid expansion is primarily driven by increasing demand for efficient and sustainable transportation solutions, which necessitates a keen understanding of the electrical specifications and performance capabilities of electric motors used in vehicles.

Additionally, the global automotive micro-motor market is another critical area, projected to see substantial growth from $56.275 million in 2025 to around $49.564 million by 2033, with a stable compound annual growth rate of 1.6%. The application of these micro-motors spans various functionalities, such as power windows, wipers, and electric power steering. Hence, selecting the correct motor type based on power consumption and specific application requirements becomes essential for optimizing performance and longevity in automotive systems, ultimately influencing the vehicle's efficiency and user experience.

How to Choose the Right Electric Motor for Your Specific Needs - Understanding Your Application Requirements for Electric Motors

| Application Type | Motor Type | Power Rating (kW) | Voltage (V) | Efficiency (%) | RPM | Mounting Type |

|---|---|---|---|---|---|---|

| Conveyor Systems | AC Induction Motor | 5 | 230 | 90 | 1500 | Foot Mount |

| Pumps | Submersible Motor | 3 | 400 | 85 | 2900 | Vertical Mount |

| Fans | Brushless DC Motor | 1 | 12 | 80 | 1800 | Bracket Mount |

| Robotics | Stepper Motor | 0.5 | 24 | 75 | 400 | Flush Mount |

Evaluating Different Types of Electric Motors Available in the Market

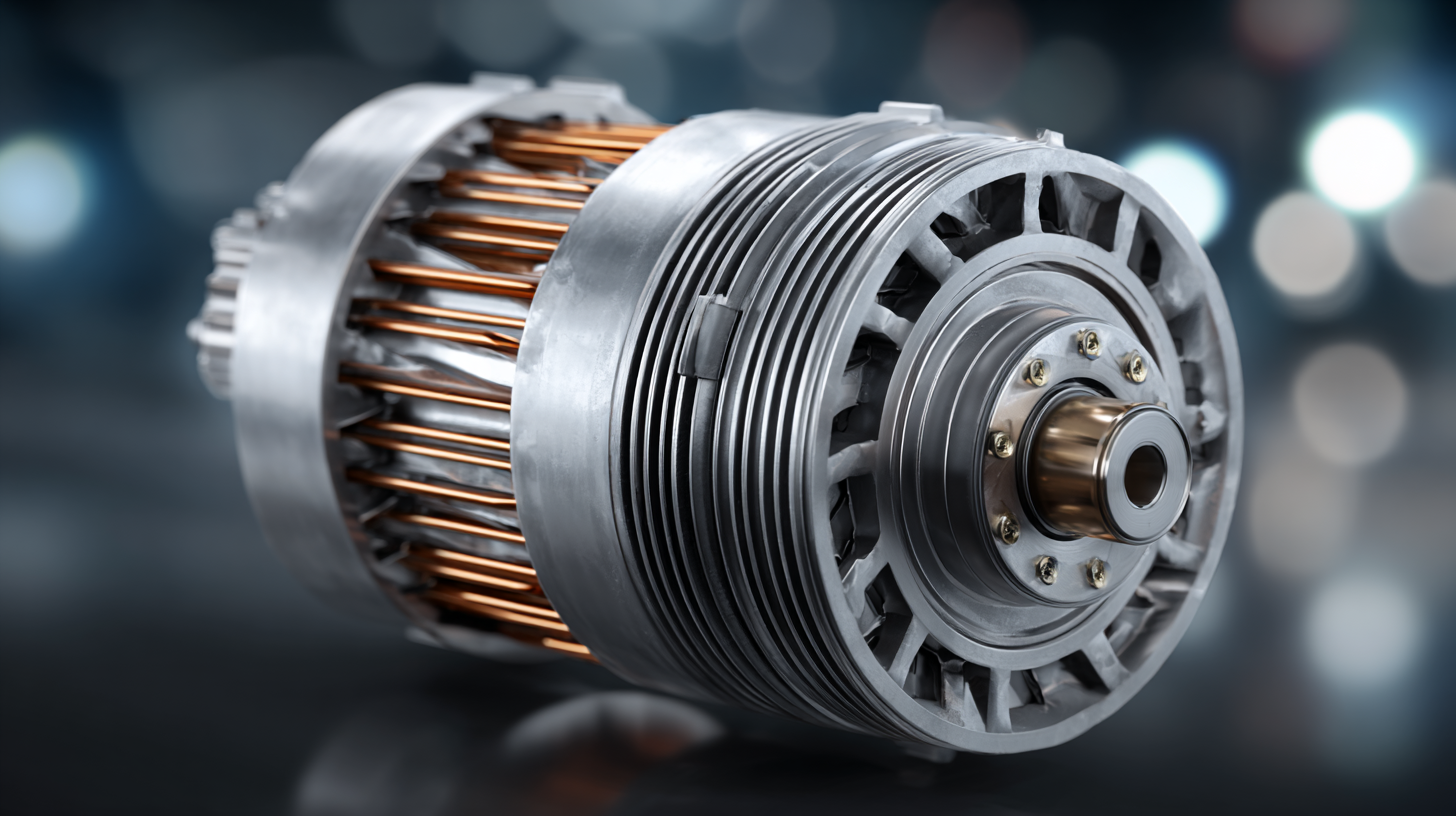

When selecting an electric motor, it's crucial to evaluate the various types available in the market based on your specific application requirements. Electric motors can be broadly categorized into AC motors and DC motors.

AC motors, including induction and synchronous types, are ideal for industrial applications due to their durability and efficiency. According to a report by the International Energy Agency, AC motors account for approximately 70% of all electrical energy consumed in manufacturing processes. This demonstrates their predominance in the market and highlights the need for careful consideration when making a choice.

AC motors, including induction and synchronous types, are ideal for industrial applications due to their durability and efficiency. According to a report by the International Energy Agency, AC motors account for approximately 70% of all electrical energy consumed in manufacturing processes. This demonstrates their predominance in the market and highlights the need for careful consideration when making a choice.

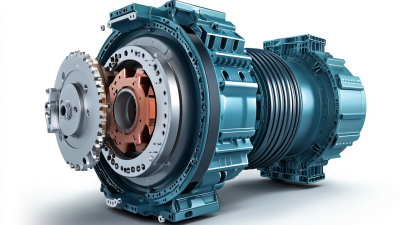

On the other hand, DC motors, particularly brushed and brushless variants, are favored in applications requiring precise speed control and higher torque at lower speeds. A recent market analysis by Market Research Future indicates that the global DC motor market is expected to grow at a CAGR of 8% from 2021 to 2027, driven by advancements in automation and robotics.

When assessing your needs, consider factors such as torque and speed requirements, power supply availability, and operational environment, as these can significantly influence the performance and efficiency of the motor you choose. Making an informed decision will ensure that the electric motor not only meets your current needs but also aligns with future operational demands.

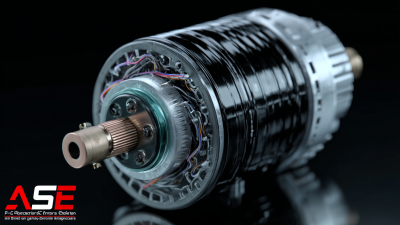

Assessing Power, Voltage, and Speed Specifications for Selection

When choosing the right electric motor, assessing power, voltage, and speed specifications is crucial for ensuring optimal performance. The power rating of a motor, typically measured in watts or horsepower, determines how much work it can perform. It's essential to match the motor's power output with the requirements of the application. For instance, a motor used in a conveyor system will need sufficient power to move heavy loads efficiently, while a smaller fan may require significantly less power.

Voltage specifications are equally important, as they dictate how the motor will interact with existing electrical systems. Selecting a motor with the correct voltage rating ensures compatibility and safety. Motors typically operate on low voltage (such as 12V or 24V) or standard mains voltage (like 110V or 220V). It's critical to consider the power supply available in your setup to avoid overloads or inefficiencies.

Lastly, speed specifications, often indicated in revolutions per minute (RPM), influence the motor’s operational effectiveness. Different applications demand different speeds; for instance, a pump might require a constant speed for fluid transfer, whereas a torque-dependent application could benefit from variable speed options. Understanding the specific speed requirements of your project will guide you in selecting a motor that delivers the desired performance without compromising on reliability.

Considering Environmental Factors and Operating Conditions

When selecting an electric motor, understanding the environmental factors and operating conditions is crucial. Factors such as temperature, humidity, and exposure to chemicals can significantly impact the performance and durability of the motor. For instance, if the motor will be used in a high-humidity environment, it's essential to choose a model with adequate sealing and corrosion-resistant materials. Additionally, consider the ambient temperature range, as some motors are designed for extreme conditions, while others might overheat in hot environments.

Tips: Always check the motor's IP (Ingress Protection) rating to ensure it’s suitable for the intended environment. If you anticipate exposure to dust, moisture, or chemicals, opt for a motor with a higher IP rating to enhance its longevity.

Furthermore, operating conditions such as load requirements, duty cycles, and installation space will dictate your motor choice. A motor operating under heavy loads will require different specifications than one used in light-duty applications. Evaluate whether the motor will be used continuously or intermittently, as this will also influence the thermal management needs.

Tips: Be sure to analyze the torque and speed requirements accurately before making your decision. Selecting a motor that closely matches your application will help avoid inefficiencies and minimize wear.

Budgeting and Long-term Maintenance for Your Electric Motor Choice

When selecting the ideal electric motor, budgeting and long-term maintenance are crucial considerations. According to a report by the International Electrotechnical Commission (IEC), operational costs can account for up to 90% of the total lifecycle cost of an electric motor. Hence, an initial low-cost motor could lead to significant expenses in energy consumption and maintenance over time. Investing in a high-quality motor with improved efficiency ratings can lead to substantial savings, with efficient motors potentially reducing energy costs by 30% or more compared to standard options.

Moreover, long-term maintenance impacts both budget and operational efficiency. A study from the Electric Power Research Institute (EPRI) indicates that regular maintenance can extend the lifespan of electric motors by as much as 50%. Implementing a proactive maintenance strategy not only reduces unexpected downtimes but also mitigates higher repair costs that often arise from neglect. Choosing motors that are easy to maintain, such as those with accessible components for lubrication or inspections, can save time and resources in the long run, ensuring a dependable operation tailored to specific needs.

Electric Motor Selection: Budgeting and Long-term Maintenance Costs

This chart compares the initial costs and annual maintenance costs associated with different tiers of electric motors. Choosing the right model requires consideration of both upfront expenditures and ongoing upkeep. Budget motors have lower initial costs but higher maintenance, while high-end models are more expensive initially but have lower maintenance costs over time.

Related Posts

-

Rising Above Tariff Challenges: How China's Best Electric Motor Manufacturers Thrive

-

The Pride of China Delivering Best Break Electric Motors to the World

-

Empowering Your Operations: Discovering Benefits of 3ph Electric Motors for Global Sourcing

-

Envisioning Tomorrow: The Evolution of 3ph Electric Motors in Industry

-

Maximize Efficiency with Exceptional After Sales Support for the Best Industrial Motor

-

The Future of Innovation in Best 3ph Electric Motor Technology

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top