How to Choose the Right Air Compressor for Your Needs in 2025

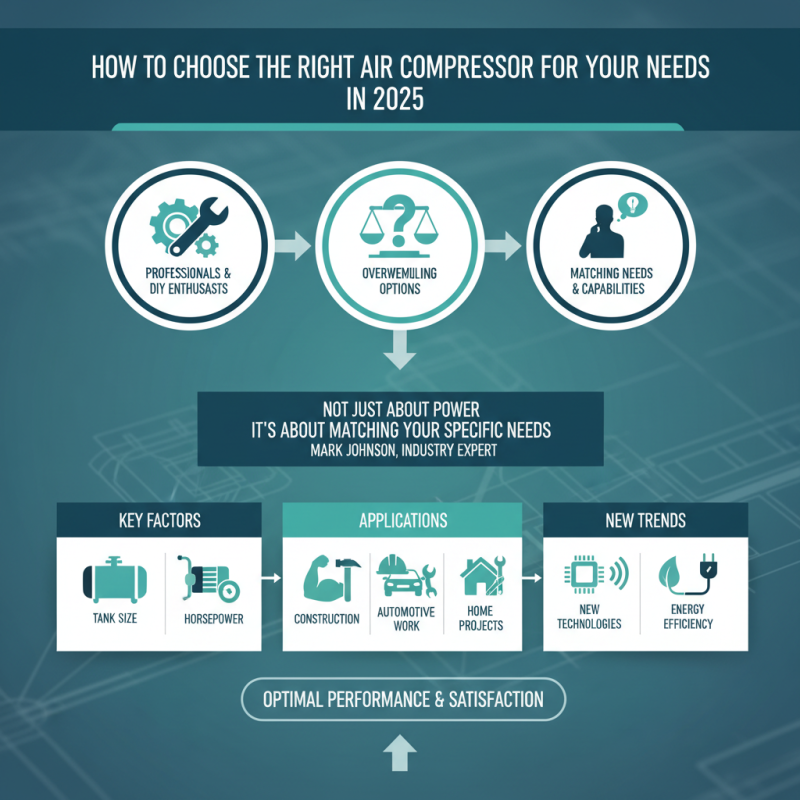

In the rapidly evolving landscape of the air compressor industry, making the right choice is pivotal for both professionals and DIY enthusiasts alike. As we move into 2025, the options available can often feel overwhelming. Industry expert Mark Johnson emphasizes this point succinctly, stating, "Selecting the right air compressor is not just about power; it’s about matching your specific needs with the right capabilities." This underscores the importance of understanding your requirements, which can range from the type of tasks to the frequency of use.

When considering an air compressor, various factors come into play, including tank size, horsepower, and portability. Each element plays a crucial role in determining which compressor will serve your needs best, whether for construction, automotive work, or home projects. With new technologies emerging and energy efficiency becoming a priority, being informed will help you navigate the myriad options available in the market. As we delve deeper into the nuances of selecting the right air compressor, it becomes clear that understanding your unique needs is essential for ensuring optimal performance and satisfaction.

Understanding the Different Types of Air Compressors Available in 2025

When choosing the right air compressor in 2025, it's crucial to understand the various types available on the market. Generally, air compressors can be categorized into three main types: reciprocating, rotary screw, and scroll compressors. Each type has its own unique features and benefits, catering to different needs and applications.

Reciprocating compressors are often the go-to option for smaller tasks or projects that require portability. They utilize a piston-driven mechanism to compress air, making them ideal for DIY enthusiasts and light industrial uses.

On the other hand, rotary screw compressors are designed for more demanding applications, providing continuous airflow and higher efficiency suited for heavy-duty industrial tasks. Their robust construction allows for extensive use in factories and large workshops.

Lastly, scroll compressors operate quietly and efficiently, making them a popular choice for HVAC systems and sensitive environments where noise levels are a concern.

Understanding these types of air compressors will greatly assist you in selecting the right one for your specific needs in 2025. Evaluating the requirements of your tasks—such as air demand, duty cycle, and required pressure—will help you make an informed decision that aligns with your intended applications.

Identifying Your Specific Air Compression Needs and Applications

When selecting an air compressor, it is crucial to first identify your specific air compression needs and applications. Consider what tasks you intend to perform with the compressor, as different applications require varying pressure levels and airflow rates. For instance, if you plan to power pneumatic tools or perform spray painting, you will need a compressor that can deliver a consistent and adequate supply of compressed air at the required PSI (pounds per square inch). Understanding the tools and equipment you will use will guide you in determining the required specifications.

Moreover, evaluating the scale of your operation is essential. Smaller tasks, such as using an airbrush or inflating tires, may only necessitate a portable, low-capacity compressor. However, for industrial or commercial applications, a heavy-duty compressor with higher capacity and durability is essential to meet increased demand and extended operation times. Additionally, consider the power source that suits your environment; electric compressors are ideal for indoor use, while gas-powered ones may be more suitable for outdoor job sites. By taking the time to assess these factors, you can make an informed choice that aligns with your specific air compression needs.

How to Choose the Right Air Compressor for Your Needs in 2025

| Application | Required Pressure (PSI) | Tank Size (Gallon) | Horsepower (HP) | Type of Compressor |

|---|---|---|---|---|

| Nail Gun | 90-120 | 6 | 2 | Portable |

| Airbrush Painting | 20-30 | 3 | 1 | Diaphragm |

| Spray Painting | 40-60 | 8 | 3 | Piston |

| Inflating Tires | 30-50 | 2 | 1.5 | Portable |

| Powering Air Tools | 90-150 | 20 | 5 | Stationary |

Evaluating Key Features and Specifications When Choosing an Air Compressor

When selecting the right air compressor in 2025, it’s crucial to evaluate key features and specifications that align with your specific needs. One of the primary factors to consider is the compressor’s horsepower (HP) rating, which directly influences its power output and efficiency. According to industry data, compressors with an HP range from 1.5 to 5 are optimal for most small to medium-sized applications, offering a good balance between performance and energy consumption.

Additionally, take note of the CFM (cubic feet per minute) rating, which indicates the volume of air the compressor can deliver. For instance, a compressor that offers at least 6 CFM at 90 PSI is suitable for operating impact wrenches and spray guns, making it a valuable asset for many workshops.

Another significant specification to assess is the tank size, typically measured in gallons. A larger tank can provide a more steady airflow without frequent cycling; however, it may increase the overall weight and footprint of the unit. Reports from the Air Compressor Manufacturers Association (ACMA) suggest that a tank size of 20-30 gallons is generally effective for average users, while heavy-duty tasks may require tanks exceeding 50 gallons. Additionally, consider the noise level of the compressor, as models under 70 decibels are often preferred for noise-sensitive environments. By thoroughly understanding these specifications, users can ensure they select an air compressor that effectively meets their operational demands while maintaining efficiency and performance throughout its lifespan.

Comparing Energy Efficiency and Operating Costs of Air Compressors

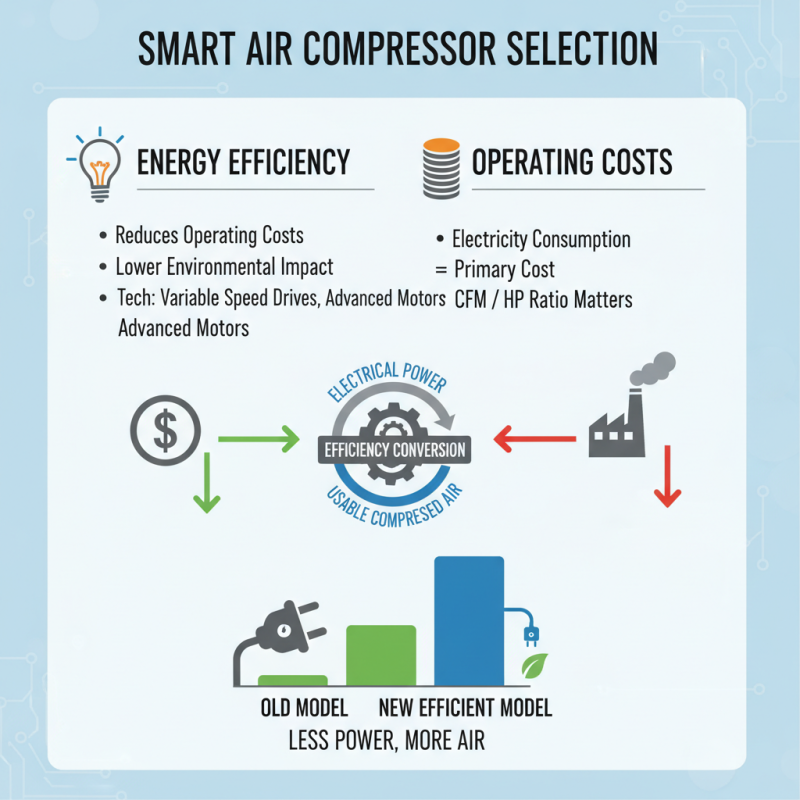

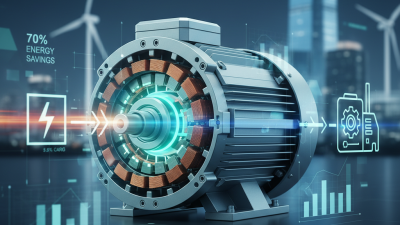

When selecting an air compressor, understanding energy efficiency and operating costs is paramount. Energy efficiency not only determines the operational expenses over time but also impacts the overall environmental footprint. Compressors are evaluated by their horsepower and CFM (Cubic Feet per Minute) ratings, but it's crucial to consider how efficiently they convert electrical energy into usable compressed air. Innovations in compressor technology, such as variable speed drives and advanced motor designs, have significantly improved efficiency, allowing users to select models that consume less power while delivering higher performance.

Operating costs extend beyond initial purchase prices, involving long-term expenses like maintenance, energy consumption, and potential downtime. A compressor that operates at a lower energy cost can save money in the long run, especially in applications requiring continuous operation. Additionally, regular maintenance, proper sizing for specific tasks, and investing in energy-efficient models can significantly reduce the total cost of ownership. Factors such as duty cycle and load requirements also play a vital role in determining efficiency, ensuring that users choose configurations that align with their specific operational needs and budget constraints.

Considering Size, Portability, and Maintenance Requirements for Your Compressor

When selecting the right air compressor for your needs in 2025, it is essential to consider its size, portability, and maintenance requirements. The size of the compressor greatly influences its performance and suitability for various tasks. For home or light-use applications, a smaller, compact unit may suffice, while larger projects or commercial use might necessitate a more powerful, bulkier machine. Evaluating the space where the compressor will be used is crucial; ensure that it fits comfortably without compromising accessibility.

Portability is another vital factor to keep in mind, especially for those who require an air compressor for various locations. If mobility is a priority, look for lightweight models with easy-to-grab handles or wheels that make transportation hassle-free. Consider the power source as well; electric compressors are often heavier but can deliver consistent performance, while gas-powered ones offer greater flexibility in remote locations but typically require more maintenance.

Lastly, maintenance requirements should not be overlooked. Different compressors have varying upkeep needs, which can affect long-term usability and cost-effectiveness. Research models that have features like oil-free operation for easier maintenance or built-in filters to reduce wear and tear. Understanding the maintenance schedule and the availability of replacement parts can help ensure that your compressor remains in optimal condition, ultimately supporting your specific needs effectively.

Related Posts

-

How to Choose the Right Air Compressor for Your Needs and Applications

-

5 Effective Tips to Maximize Efficiency of Your Air Compressor for Optimal Performance

-

Exploring Air Compressor Innovations: Insights from the 138th Canton Fair 2025 in China

-

Ultimate Guide to Selecting the Best Three Phase AC Motor for Your Industrial Needs

-

Envisioning Tomorrow: The Evolution of 3ph Electric Motors in Industry

-

How to Choose the Right Induction Motor for Your Industrial Applications

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top