The Ultimate Guide to Choosing the Right AC Motor for Your Manufacturing Needs

In today’s manufacturing landscape, the selection of the right AC motor is crucial for optimizing efficiency and performance. According to a report by the International Electric Motor Systems Market, the global AC motor market is projected to reach $32.29 billion by 2026, reflecting a CAGR of 6.5% from 2021. This compelling data underscores the importance of choosing the appropriate AC motor, as it can significantly impact operational costs and the overall productivity of manufacturing processes. With advancements in technology and a diverse range of options available, it can be overwhelming for manufacturers to navigate through the specifications and capabilities of different AC motors. This ultimate guide aims to simplify the decision-making process by providing valuable insights and actionable tips that cater to varied manufacturing needs, ensuring that you make the best choice for your specific application requirements.

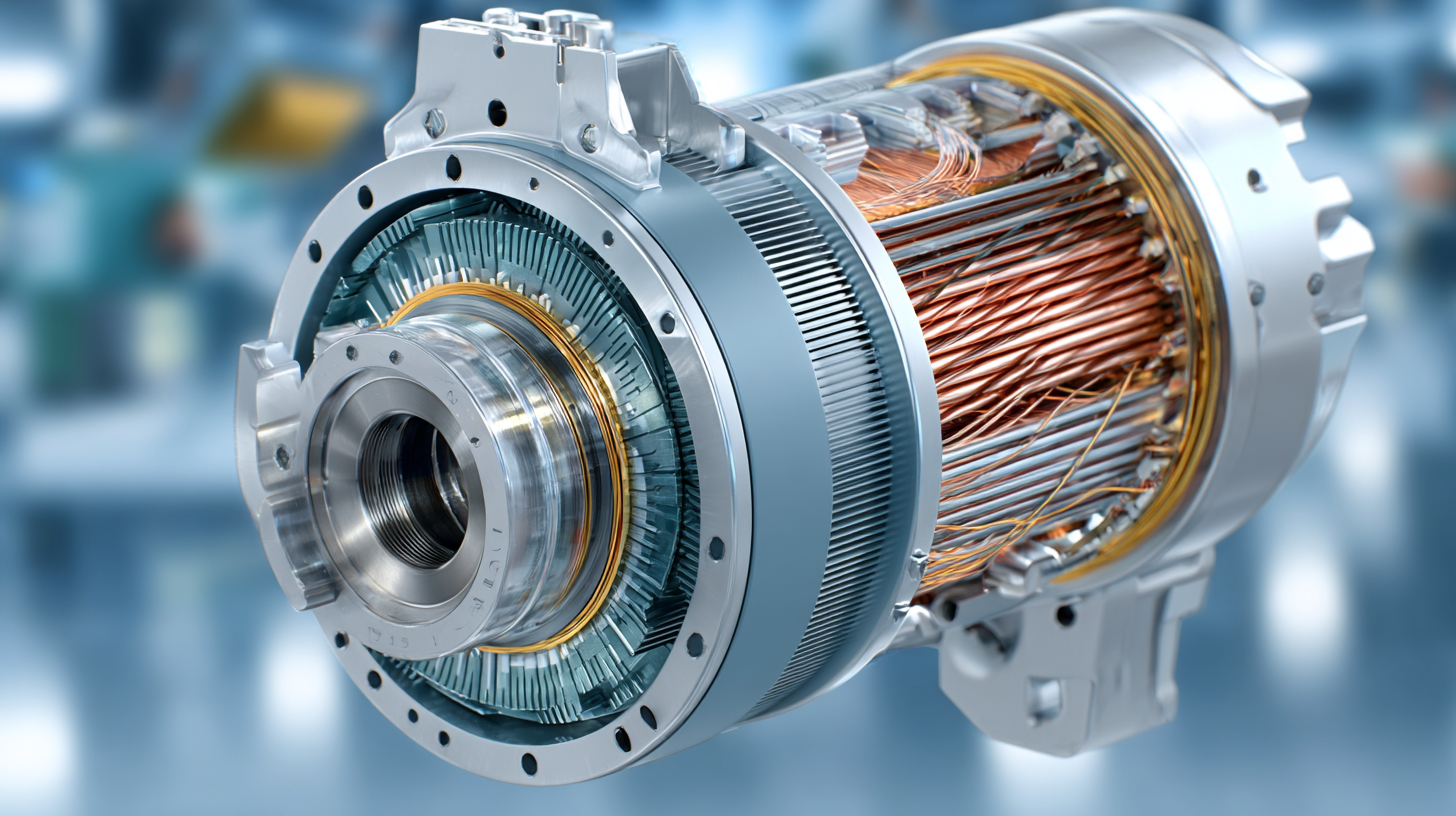

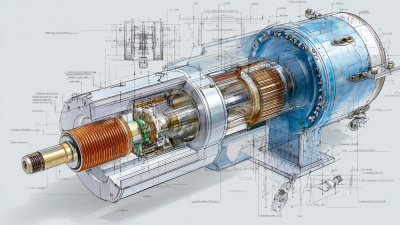

Understanding the Different Types of AC Motors: A Comprehensive Breakdown

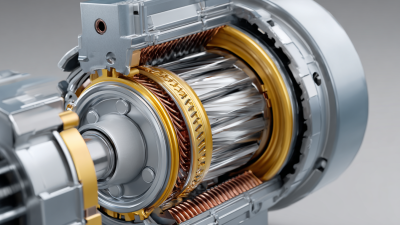

When selecting the right AC motor for your manufacturing needs, understanding the different types of AC motors is essential. AC motors can broadly be categorized into synchronous and asynchronous motors, with each type offering unique benefits. Synchronous motors operate at a constant speed, making them ideal for applications requiring precision. On the other hand, asynchronous motors, commonly three-phase, are more widely used due to their simplicity and robustness, especially in large industrial settings.

**Tips:** When choosing an AC motor, consider the torque requirements of your applications. Motors designed for higher torque may be necessary for heavy machinery. Additionally, assess the power supply conditions; understanding whether a high-efficiency or standard motor suits your environment can help optimize performance and reduce operational costs.

Furthermore, pay attention to the motor's speed capabilities. Some applications may demand variable speeds, which can be efficiently managed with variable frequency drives. These drives allow you to adjust motor speeds dynamically, enhancing operational efficiency and reducing energy consumption.

In summary, evaluating the specific needs of your manufacturing process and weighing these factors will guide you in selecting the most appropriate AC motor for your operations.

Key Performance Metrics to Consider When Selecting an AC Motor

When selecting an AC motor for manufacturing applications, it's crucial to consider key performance metrics that can greatly influence operational efficiency and cost-effectiveness. According to a report by the International Energy Agency (IEA), AC motors account for approximately 65% of global industrial electricity consumption. This underscores the importance of choosing efficient models that match specific operational requirements.

One of the primary metrics to evaluate is the motor's efficiency rating, often categorized under the IE3 or IE4 standards for premium efficiency. Motors that meet these classifications can reduce energy consumption by up to 30% compared to standard models, offering significant cost savings over their lifespan. Additionally, factors such as torque density and thermal performance play critical roles in ensuring that the motor can handle varying loads without overheating or compromising reliability. The latest industry data indicate that motors with higher torque density can provide more power in a smaller footprint, allowing for more flexible manufacturing layouts.

Lastly, it's essential to assess the motor's speed control capabilities. Advanced AC motors equipped with variable frequency drives (VFDs) can adjust their speed according to process demands, achieving energy savings of 20-50%, according to the U.S. Department of Energy. Such versatility not only enhances overall system performance but also contributes to a more sustainable manufacturing process. These metrics collectively support the decision-making process for selecting the right AC motor tailored to specific manufacturing needs, aligning performance with long-term operational goals.

The Ultimate Guide to Choosing the Right AC Motor for Your Manufacturing Needs

| Motor Type | Horsepower (HP) | Voltage (V) | Efficiency (%) | Service Factor | Starting Method |

|---|---|---|---|---|---|

| Induction Motor | 5 HP | 460 V | 90% | 1.15 | Direct-on-Line |

| Synchronous Motor | 10 HP | 230 V | 92% | 1.0 | Soft Start |

| Permanent Magnet Motor | 3 HP | 380 V | 95% | 1.25 | Variable Frequency Drive |

| Gear Motor | 7.5 HP | 480 V | 88% | 1.0 | Star-Delta |

Energy Efficiency Ratings: How to Optimize Power Consumption in Manufacturing

When selecting an AC motor for your manufacturing needs, understanding energy efficiency ratings is crucial for optimizing power consumption. Energy-efficient motors not only reduce operational costs but also minimize environmental impact. The effectiveness of an AC motor is often quantified by its efficiency rating, which indicates how much of the electrical energy is converted to useful mechanical energy. The higher the rating, the less energy waste, making it essential to consider when making your choice.

**Tip 1:** Always look for motors that meet or exceed the latest efficiency standards, such as NEMA Premium ratings. These motors are designed to operate more efficiently than standard models, translating to significant energy savings over time.

**Tip 2:** Consider variable frequency drives (VFDs) to enhance the adaptability of your AC motors. By regulating the motor speed and torque, VFDs can further optimize energy use, especially in applications with varying loads.

Choosing the right AC motor combined with awareness of energy efficiency can lead to substantial improvements in both productivity and cost savings within your manufacturing processes.

Cost-Effectiveness Analysis: Balancing Quality and Budget in Motor Selection

When selecting an AC motor for your manufacturing operations, a thorough cost-effectiveness analysis is indispensable. The ideal motor should not only meet your performance requirements but also align with your budget constraints. This involves evaluating both the upfront costs and long-term operational expenses, which include energy consumption, maintenance, and potential downtime. A high-quality motor may come with a higher initial investment, but the savings gained from reduced energy consumption and maintenance needs can offset this cost over time.

Furthermore, it is essential to consider the overall quality of the motor in relation to its price. Investing in a durable motor with advanced technology may mean paying more upfront, yet this can significantly enhance productivity and reduce the frequency of replacements. By carefully analyzing these factors, manufacturers can make informed decisions that maximize operational efficiency while staying within budgetary limits. Balancing quality and cost leads to a sustainable approach to motor selection that not only meets current manufacturing demands but also positions the business for future growth.

Future Trends in AC Motor Technology: Innovations Shaping the Industry

The realm of AC motor technology is swiftly evolving, driven by innovations that enhance efficiency and performance. One significant trend is the integration of smart technology in motors, allowing for real-time monitoring and data analytics. This capability not only improves operational efficiency but also facilitates predictive maintenance, reducing downtime and maintenance costs. Manufacturers can leverage these advancements to optimize their processes and reduce energy consumption.

When selecting an AC motor, consider the motor’s energy efficiency rating. Higher-rated motors might have a higher upfront cost, but they offer substantial savings on energy bills in the long run. Incorporating energy-efficient solutions in your manufacturing setup is not just cost-effective; it also aligns with sustainability goals that many companies are pursuing today.

Another noteworthy trend is the emergence of brushless AC motors, which offer enhanced reliability and lower maintenance requirements compared to traditional brushed motors. These motors are particularly beneficial for applications that demand high precision and durability. When evaluating your options, ensure you assess the specific requirements of your application to choose a motor that delivers the right performance and longevity.

The Ultimate Guide to Choosing the Right AC Motor for Your Manufacturing Needs

This bar chart showcases the efficiency ratings of various types of AC motors commonly used in manufacturing. The data illustrates how advancements in technology are enhancing motor efficiency across different sectors, ensuring better performance and energy savings.

Related Posts

-

A Comprehensive Guide to Understanding AC Motors for Global Buyers

-

10 Reasons Why the Best AC Motors Outperform Competitors in Efficiency and Longevity

-

How to Choose the Best Three Phase Ac Motor for Your Industrial Needs

-

Unveiling the Specifications of the Best AC Electric Motor: A Comprehensive Technical Review

-

Ultimate Guide to Selecting the Best Three Phase AC Motor for Your Industrial Needs

-

5 Powerful Reasons to Choose the Best Three Phase AC Motor for Your Business

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top