How to Choose the Right Single Phase AC Motor for Your Needs?

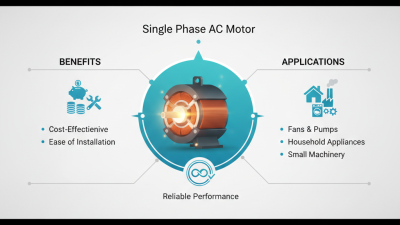

Choosing the right Single Phase AC Motor can significantly impact your operations. According to industry reports, single phase AC motors represent about 80% of total motor sales globally. These motors are widely used in residential and light commercial applications due to their efficiency and performance.

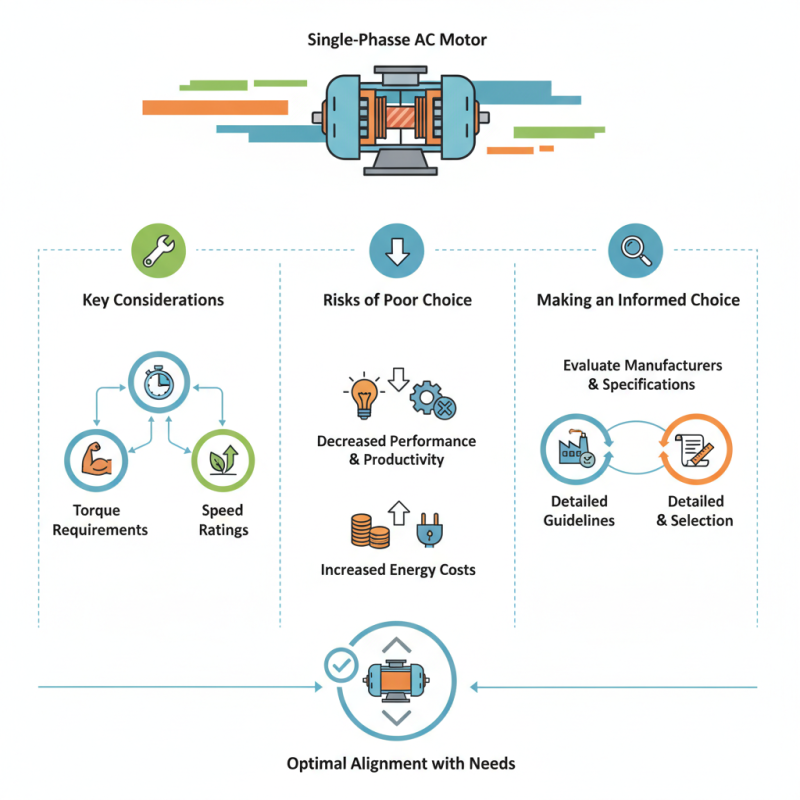

However, selecting the right model isn't always straightforward. Factors like torque requirements, speed ratings, and efficiency ratings must be carefully considered. Misjudging these aspects can lead to decreased performance and increased energy costs. Inadequate power can hinder productivity, particularly in crucial applications.

Moreover, not all motors are created equal. Variations in quality and design can lead to frustrations. It's essential to critically evaluate manufacturers and their specifications. Relying on detailed guidelines will aid in making an informed choice. This ensures that the Single Phase AC Motor you select aligns perfectly with your specific needs.

Consider Your Operational Requirements: Power, Voltage, and Frequency

When selecting a single-phase AC motor, understanding your operational requirements is crucial.

Start by assessing your power needs. Different applications require varied power levels. For example, a small fan needs less power than a heavy-duty compressor.

Evaluate the wattage required for your specific task. Also, determine the voltage necessary for your motor. Common voltages include

120V and 240V. Ensure your power source matches the motor voltage to prevent performance issues.

Consider the frequency as well. Most regions operate on either 50Hz or 60Hz. This can greatly impact motor performance.

A mismatch may lead to inefficient operation or even damage. Check local standards before deciding.

Tips: Always round up your power requirements. It's better to have a little extra capacity. Monitor how often the motor will run, too. Continuous operation can lead to overheating if not properly rated.

Lastly, don't hesitate to consult with an expert if you feel uncertain. An improperly rated motor can cost you in repairs and downtime.

Evaluate the Motor's Efficiency Rating and Energy Consumption Impact

When selecting a single-phase AC motor, understanding its efficiency rating is crucial. According to the Department of Energy, energy-efficient motors can reduce energy consumption by 2-10% compared to standard models. An efficiency rating of 85% or higher is often recommended for optimal performance. These motors save energy, which leads to lower utility costs.

Energy consumption impacts overall operational costs. A motor running at 1 horsepower for 2,000 hours annually may consume around 1,500 kWh, depending on its efficiency. Choosing a motor with a 90% efficiency rating could reduce this consumption to approximately 1,333 kWh. This can translate into significant savings over time. However, not all applications may justify the investment in high-efficiency models. Sometimes, the upfront cost can outweigh the long-term savings.

Evaluating the load requirements is essential. Underloading a motor can cause inefficiencies, resulting in wasted energy. Conversely, frequent overloads lead to motor damage and increased maintenance costs. Users should analyze their specific needs closely, weighing the benefits of high efficiency against the operational context. Making an informed choice is often more complex than it appears.

Understand the Importance of RPM and Torque for Application Suitability

When selecting a single-phase AC motor, understanding RPM and torque is vital. RPM, or revolutions per minute, indicates how fast the motor spins. This speed affects performance significantly, especially for different applications. For example, a motor with high RPM is often ideal for applications requiring quick movement. In contrast, a low RPM motor offers more control and power for heavy-duty tasks, such as driving pumps.

Torque, measured in pound-feet or Newton-meters, reflects a motor's ability to perform work. A high torque value means more strength to move heavy loads. However, achieving a balance between RPM and torque can be tricky. A motor with very high RPM may not provide the necessary torque, leading to performance issues. Consider the specific work requirements. A motor that excels in one area may lack in another. Unfortunately, this can result in poor operational efficiency.

Evaluate your needs carefully. Think about what you are trying to achieve. An application meant for high-speed tasks may suffer with the wrong torque. Testing different motors may help find the perfect match. Remember, sometimes what seems ideal is not. Each choice carries consequences. Understanding the balance of RPM and torque is crucial for optimal performance.

Assess Environmental Conditions and Mounting Options for Installation

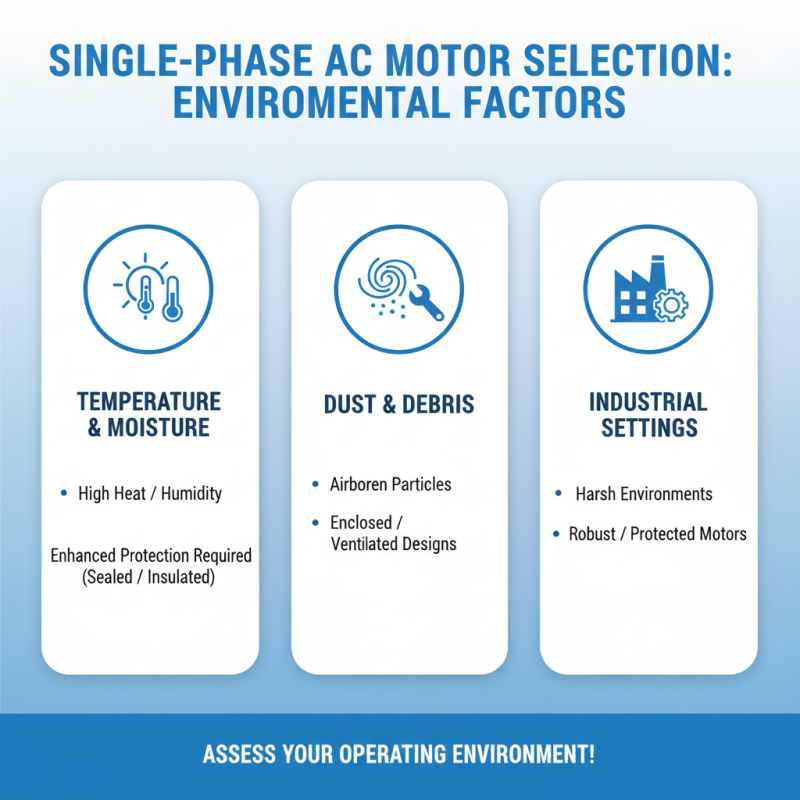

When selecting a single-phase AC motor, environmental conditions play a critical role. Assessing the area where the motor will operate is essential. Are there high temperatures or moisture? If yes, you may need a motor with enhanced protection against these elements. Dust and debris can also impact motor performance. In industrial settings, consider enclosed or ventilated designs to protect against foreign particles.

Mounting options are equally important. The space available may dictate the motor's size and orientation. Wall-mounted systems might need specific brackets or supports. Horizontal mounts can require a solid base to avoid vibrations. Uneven surfaces could lead to issues over time. Think about accessibility for maintenance and service. A well-placed motor simplifies future checks and repairs.

Sometimes, it’s easy to overlook these details. Rushing through the process can lead to problems later. Taking time to evaluate every aspect increases the chances of finding the right motor. Planning ahead is crucial for optimal performance and durability.

Choose Between Capacitor-Start and Split-Phase Motor Types Based on Needs

Choosing the right single-phase AC motor is crucial for various applications. When deciding between capacitor-start and split-phase motor types, it helps to understand their features. Capacitor-start motors provide higher starting torque. They are ideal for applications requiring heavy loads at startup. However, they are typically more expensive and can be bulkier.

Split-phase motors, on the other hand, are simpler in construction. They offer moderate starting torque and are suited for lighter applications. These motors are efficient and provide reliable performance. Yet, they might struggle with high starting demands. Consider your application carefully before making a decision. Think about load requirements, environmental conditions, and energy efficiency.

Be aware of trade-offs in each motor type. Capacitor-start motors can potentially overheat if not matched correctly to the load. Split-phase motors can lose efficiency over time. It's essential to balance performance needs with budget constraints. Evaluate your situation thoroughly to avoid common pitfalls. Making a well-informed choice will lead to better productivity in the long run.

Related Posts

-

Why Choose a Single Phase AC Motor? Benefits and Applications Explained

-

Top 7 Benefits of Using Single Phase AC Motors for Your Home Applications

-

2025 Top 5 Single Phase AC Motors: Best Picks for Efficiency and Performance

-

The Ultimate Guide to Choosing the Right Electrical Fan Motor for Your Home

-

How to Choose the Right Air Compressor for Your Needs in 2025

-

Maximize Efficiency with Exceptional After Sales Support for the Best Industrial Motor

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top