How to Choose the Right Induction Motor for Your Application?

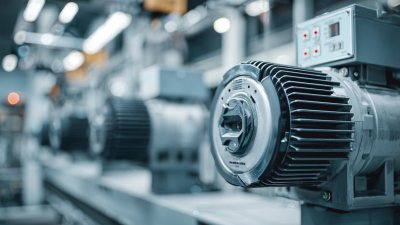

Choosing the right induction motor for your application is crucial. An incorrect selection can lead to inefficiencies and unexpected costs. Induction motors are widely used in various industries due to their reliability and performance. They power everything from small fans to large industrial machines.

When selecting an induction motor, consider key factors like power requirements and speed. Every application has unique demands. Ignoring these details can result in poor performance. For example, an oversized motor may waste energy. A motor that is too small may fail to meet operational needs.

Think about environmental conditions too. Motors must withstand specific temperatures and humidity levels. This often gets overlooked during the selection process. Carefully analyzing your application will lead to better decisions. Ultimately, the right induction motor can enhance productivity and reduce long-term costs. However, this choice requires reflection and fine-tuning based on real-world testing and outcomes.

Understanding the Basics of Induction Motors

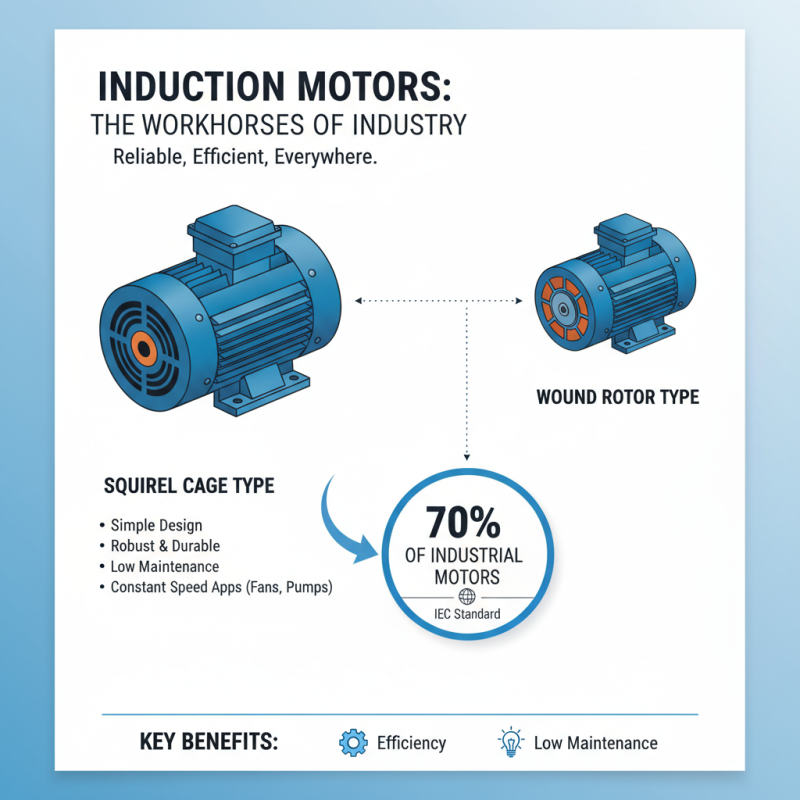

Choosing the right induction motor starts with understanding its basics. Induction motors are widely used in various industries due to their durability and efficiency. According to industry reports, around 70% of industrial motors are induction types. They work on electromagnetic induction, which means they use electricity to generate a magnetic field that turns the rotor. This process is efficient and reliable.

When selecting an induction motor, consider its power rating. The power needs can vary significantly based on your specific application. For small-scale setups, a motor rated below 5 HP may suffice. However, larger operations often require motors with ratings over 50 HP. Energy efficiency ratings also play a key role. Motors with higher efficiency can reduce operational costs over time.

Tip: Always verify the motor's cooling method. A motor's cooling helps its efficiency. Insufficient cooling can lead to overheating and reduced lifespan.

Another consideration is the type of load the motor will drive. Constant torque loads differ from variable torque loads. Each type affects the motor's selection. Improper matching can lead to energy waste.

Tip: Review the motor’s duty cycle. It should fit your operational environment to enhance performance. Always assess the installation space and environmental factors.

Key Factors to Consider When Selecting an Induction Motor

Choosing the right induction motor is crucial for operational efficiency. Key factors include power rating, efficiency class, and environment. An optimal power rating matches the specific load profile of your application. It ensures that the motor provides adequate torque without excessive energy loss. According to a recent industry report, motors account for nearly 70% of industrial electricity consumption. A mismatch can lead to performance issues.

Efficiency is another important consideration. The efficiency class of a motor dictates how much energy it converts into usable work. Using high-efficiency motors can reduce energy costs significantly. The U.S. Department of Energy estimates that upgrading to premium efficiency motors can save facilities up to 10% on energy bills. Additionally, environmental conditions play a vital role. Motors operating in harsh environments may require special enclosures. Not considering these factors can lead to motor failure, resulting in costly downtime.

Lastly, understanding the application need is vital. Some applications need high starting torque, while others require variable speed. Not aligning these requirements may lead to inefficiencies. Hidden costs may arise from improper selection. Conducting a thorough analysis and consulting detailed specification sheets will ensure the right choice. Each application is unique; assumptions can result in suboptimal performance.

How to Choose the Right Induction Motor for Your Application? - Key Factors to Consider When Selecting an Induction Motor

| Factor | Description | Recommended Value/Range | Considerations |

|---|---|---|---|

| Power Rating | The output power required for the application. | 0.5 kW - 1000 kW | Ensure it matches load requirements. |

| Voltage | Operating voltage of the motor. | 230V, 400V, 575V | Compatibility with power supply. |

| Frequency | AC frequency for operation. | 50 Hz, 60 Hz | Match with local grid standards. |

| Speed | RPM required for the application. | 1500 RPM, 3000 RPM | Consider load speed requirements. |

| Efficiency | Energy conversion efficiency. | IE2, IE3, IE4 | Higher efficiency reduces operating costs. |

| Environment | Conditions in which the motor will operate. | Indoor, outdoor, explosive atmosphere | Ensure proper protection ratings. |

| Mounting Type | How the motor will be installed. | Foot-mounted, flanged | Consider space and installation ease. |

Types of Induction Motors and Their Applications

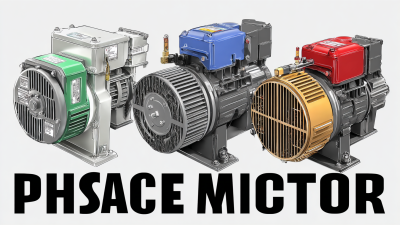

Induction motors are widely used in various applications due to their reliability and efficiency. There are primarily two types of induction motors: squirrel cage and wound rotor. Squirrel cage motors are favored for their simplicity and robustness. According to the International Electrotechnical Commission, about 70% of industrial motors belong to this category. They shine in applications requiring consistent speed and minimal maintenance, like fans and pumps.

Wound rotor motors, on the other hand, offer greater control over speed and torque. They are often employed in tasks that demand variable speed applications. Industries using heavy machinery, such as mining and metal processing, benefit from these motors' flexibility. Reports indicate that these motors account for around 10% of the total industrial motor market.

Choosing the right motor depends on specific requirements. Consider factors like load type, environmental conditions, and power availability. Data from the Electric Power Research Institute highlights that improper motor selection can lead to energy inefficiencies. Additionally, sometimes, users overlook the need for a detailed load analysis, which can result in incorrect sizing. Thus, proper evaluation is essential to ensure application success.

Evaluating Performance Specifications for Your Needs

When selecting an induction motor, it's crucial to evaluate performance specifications that align with your application needs. Start by determining the required torque and speed. The motor's rated power should match the demands of the workload. If the motor is underutilized, it can lead to inefficiency. Overload can cause damage.

Tips: Understand your duty cycle. Continuous versus intermittent duties require different motor characteristics.

Consider the environment where the motor will operate. Factors like temperature, humidity, and exposure to chemicals impact motor selection. For instance, a motor in a dusty environment may need better sealing. Misjudging these conditions can lead to early failures.

Tips: Look for a motor that meets environmental protection ratings.

Also, think about energy efficiency. High-efficiency motors may have a higher upfront cost but offer savings over time. The challenges in balancing budget and performance are often noted. Inadequate research can result in overspending or poor performance.

Tips: Review energy consumption data critically before making a decision.

Importance of Motor Efficiency and Regulations in Selection

When selecting an induction motor, efficiency is paramount. It impacts energy consumption and operational costs. According to a recent report by the International Energy Agency, electric motors account for about 45% of global electricity use in industrial applications. With rising energy prices, choosing an efficient motor can result in significant savings. Some models achieve efficiencies of over 95%, which can drastically reduce annual energy costs.

Regulations also play a critical role in motor selection. Various standards, like the IEC 60034-30, classify motors based on their energy efficiency. Compliance with these standards is not just a legal requirement; it also affects operational performance. Companies may face fines for choosing non-compliant motors. An inefficient motor may seem cheaper initially, but hidden costs accumulate over time. Higher energy bills and potential regulatory penalties can erode profit margins.

Sometimes, it's easy to overlook efficiency metrics in favor of upfront cost. However, considering long-term impacts is vital. Choosing a motor solely for initial savings can lead to regret. Reflecting on past choices can help you make informed decisions. Efficiency should guide your selection process. It’s not just about performance today, but sustainability for the future.

Related Posts

-

Rising Above Tariffs: How China's Best Induction Motors Thrive in a Competitive Market

-

Top 10 Induction Motor Types for Optimal Performance and Efficiency

-

How to Choose the Right Centrifugal Pump Motor for Your Applications

-

How to Choose the Right Gearbox Motor for Your Application

-

Exploring the Features and Applications of Best Variable Frequency Motors with Buying Tips

-

How to Choose the Best Three Phase Ac Motor for Your Industrial Needs

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top