How to Choose the Right Centrifugal Pump Motor for Your Applications

Choosing the right centrifugal pump motor is a crucial aspect for ensuring optimal performance and efficiency in various applications. As industry expert Dr. John Smith, a renowned engineer in fluid dynamics, once stated, "The selection of a centrifugal pump motor is not just about power; it’s about harmonizing the motor’s capabilities with the specific requirements of the system." This highlights the importance of understanding the operational environment, fluid characteristics, and energy efficiency when selecting a motor.

In today’s diverse industrial landscape, the right centrifugal pump motor can significantly impact productivity and sustainability. Factors such as motor speed, compatibility with variable frequency drives, and energy efficiency ratings come into play when making this critical decision. An alignment between the motor specifications and application needs ensures that the system runs smoothly, minimizing downtime and maintenance costs. By carefully evaluating these elements, users can make informed choices that lead to enhanced operational efficiency and reliability.

As we delve deeper into the process of selecting the most appropriate centrifugal pump motor, it becomes apparent that this is a multifaceted decision requiring careful consideration of both technical specifications and application requirements. Thus, understanding the nuances involved in this selection process is essential for achieving peak performance in any fluid handling system.

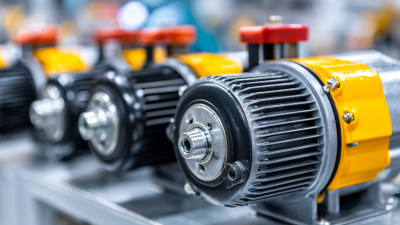

Understanding Centrifugal Pump Motors: Key Components and Functions

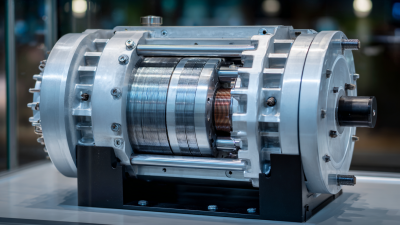

Centrifugal pump motors are crucial for efficiently converting electrical energy into mechanical energy, enabling the movement of fluids in various applications. Understanding the key components of these motors is essential for selecting the right one for your specific needs.

The primary components of a centrifugal pump motor include the stator, rotor, bearings, and casing. The stator generates a rotating magnetic field that drives the rotor, which is connected to the pump impeller. The design and materials of these components significantly influence the motor's efficiency, durability, and performance.

In addition to the structural elements, the function of the motor plays a pivotal role in determining the appropriate choice. The motor's power output, speed control, and torque characteristics must align with the requirements of the centrifugal pump and the fluid being handled. For instance, applications requiring high flow rates may benefit from a motor with higher horsepower and efficiency, while applications with variable flow demands might necessitate a motor equipped with variable frequency drive (VFD) capabilities. By carefully considering these aspects, one can select a centrifugal pump motor that optimally suits the intended application, ensuring reliable and effective fluid movement.

Identifying Your Application Requirements for Pump Motor Selection

When selecting the right centrifugal pump motor, the first step is to clearly identify the specific requirements of your application. This includes understanding the fluid characteristics such as viscosity, temperature, and density, which can greatly influence the performance and efficiency of the motor.

For instance, a higher viscosity fluid may require a motor with greater torque capabilities, while high-temperature fluids may necessitate specialized materials and cooling methods. Additionally, assessing the flow rate and head requirements is crucial, as these parameters determine the size and power of the motor necessary to achieve optimal performance.

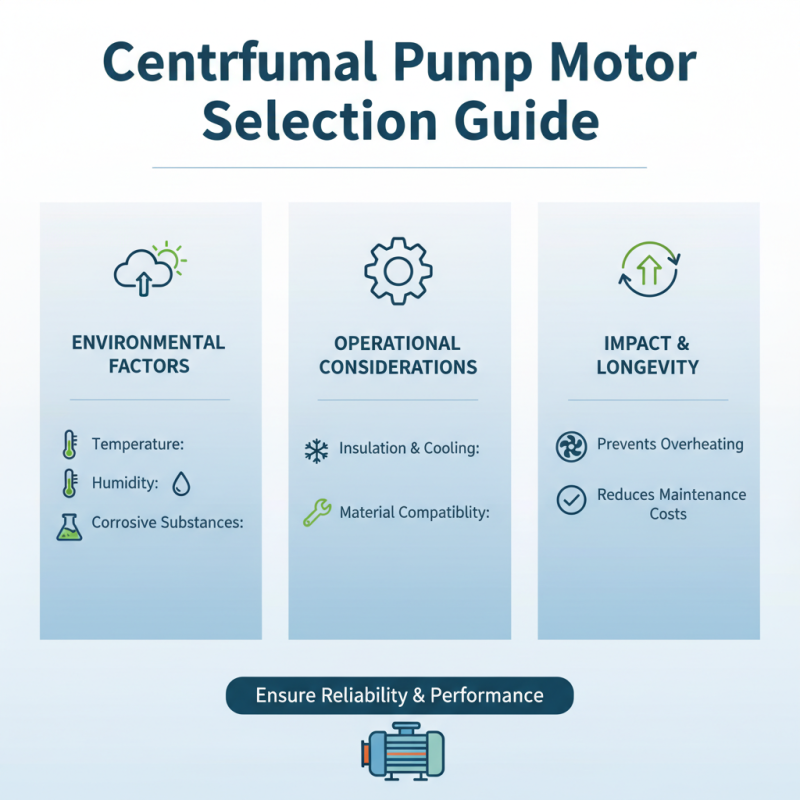

Another key consideration is the operational environment of the pump. Factors such as ambient temperature, humidity, and the presence of corrosive substances can impact the longevity and reliability of the motor. It's imperative to evaluate whether the motor needs to be explosion-proof or resistant to specific chemicals based on the application.

Furthermore, understanding the duty cycle—how often and how long the pump will run—can help in selecting a motor that can handle the operational demands without risking overheating or premature failure. By thoroughly analyzing these application requirements, you can ensure that the chosen centrifugal pump motor will align with your system’s needs and perform efficiently over time.

Evaluating Motor Types: AC vs. DC for Centrifugal Pumps

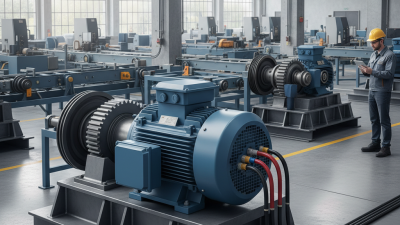

When selecting the right motor for your centrifugal pump, understanding the differences between AC and DC motors is crucial. AC motors are known for their efficiency and robustness, making them suitable for applications that require continuous operation. They are less complicated, generally requiring minimal maintenance, and are often available in a wider range of power outputs. This makes AC motors a go-to choice for many industrial applications where reliability is paramount.

On the other hand, DC motors offer immediate torque and are ideal for applications that require variable speed control. Their ability to easily adjust to different operational demands makes them perfect for systems where precise flow regulation is necessary. However, they may require more maintenance and can be less efficient than their AC counterparts, especially in constant load scenarios.

Tips: When evaluating your options, consider the following:

- First, assess your application’s operational requirements—whether speed flexibility or steady performance is more critical.

- Second, think about the power supply available; AC motors typically run on standard electrical systems, while DC motors might need additional components for regulation.

- Lastly, factor in the long-term maintenance and operational costs to ensure your choice aligns with your budget and performance goals.

Considering Efficiency and Performance Ratings in Motor Choice

When selecting a centrifugal pump motor, efficiency and performance ratings play a critical role in ensuring optimal operation and energy conservation. Efficiency, often measured as a percentage, reflects how well the motor converts electrical energy into mechanical energy. For instance, motors operating at 90% efficiency or higher are generally preferred, as they minimize energy losses and can lead to substantial reductions in operational costs.

According to the U.S. Department of Energy, inefficient motors can waste about 20% to 30% of the energy they consume, making it imperative to choose motors that meet or exceed the efficiency standards set forth in recent guidelines.

Performance ratings, including horsepower and torque, are equally important in determining the suitability of a motor for specific applications. The right motor should match the pump’s requirements to handle the intended fluid without experiencing excessive wear or failure.

A report by the Hydraulic Institute indicates that choosing a properly rated motor can improve performance consistency and extend equipment lifespan.

As industries look to meet increasing energy efficiency mandates, selecting a motor with both high efficiency and appropriate performance ratings becomes essential not only for compliance but also for maintaining the reliability of centrifugal pump systems.

Assessing Environmental and Operational Conditions Affecting Motor Selection

When selecting a centrifugal pump motor, understanding the environmental and operational conditions is crucial. Factors such as temperature, humidity, and potential exposure to corrosive substances can significantly impact motor performance and longevity. For example, in high-temperature environments, motors may require special insulation and cooling mechanisms to prevent overheating. Similarly, if the motor will be exposed to moisture or chemicals, selecting materials that can withstand such conditions is essential to ensure operational integrity and reduce maintenance costs.

Additionally, the specific application of the pump influences motor selection. If the pump operates in a consistent environment, a standard motor may suffice. However, in variable conditions, such as those involving fluctuating flow rates or frequent start-stop cycles, it’s necessary to consider motors with variable speed drives or other advanced features that can adapt to changing operational demands. Assessing these environmental and operational factors will not only enhance the efficiency of the pump system but also extend the lifespan of the motor, ultimately leading to reduced downtime and cost savings.

Related Posts

-

Understanding the Power: How Centrifugal Pump Motors Enhance Industrial Efficiency

-

Exploring Alternative Technologies for the Best Asynchronous Motor Efficiency and Performance

-

Top 5 Benefits of Using a 3ph Electric Motor for Your Industrial Applications

-

Unmatched Quality of Best Cast Iron Motors from World Leading Chinese Manufacturers

-

Exploring Best Break Motor Applications in Industry with a Step by Step Guide

-

2025 Top 5 Single Phase AC Motors: Best Picks for Efficiency and Performance

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top