How to Choose the Right Aluminum Motor for Your Project Needs

When embarking on a project that involves the selection of an Aluminum Motor, it is essential to consider various factors that align with the specific requirements of your application. Renowned industry expert Dr. James Thornton, a mechanical engineer specializing in motor technologies, emphasizes the importance of making an informed choice: "Understanding the unique specifications and capabilities of Aluminum Motors can significantly enhance both performance and efficiency in your projects."

Aluminum Motors are becoming increasingly popular due to their lightweight construction, corrosion resistance, and excellent performance characteristics. However, the plethora of options available in the market can make the selection process daunting. Factors such as power output, size, thermal management, and intended use are critical in determining the right Aluminum Motor for your needs.

As you navigate the decision-making process, it is vital to equip yourself with knowledge and insights from experts in the field. By focusing on the specific requirements of your project and understanding the advantages that Aluminum Motors can offer, you can position yourself for success in your engineering endeavors.

Understanding the Basics of Aluminum Motors

When selecting the right aluminum motor for your project, it's essential to understand the fundamental aspects that define these motors. Aluminum motors are increasingly favored in various industries due to their lightweight nature and excellent thermal conductivity. According to a report from the International Electrotechnical Commission (IEC), the demand for lightweight and efficient motors is projected to grow by 8% annually through 2025. This growth is driven by the need for energy-efficient solutions in sectors ranging from automotive to aerospace.

Understanding the specifications of aluminum motors is crucial when making a decision. Key attributes such as power output, torque, efficiency, and thermal rating can significantly impact overall performance. For instance, the efficiency ratings of aluminum motors can often exceed 90%, leading to lower operational costs and reduced energy consumption over time. Additionally, the use of aluminum in motor construction provides enhanced heat dissipation, allowing for improved reliability and longevity in high-demand applications. Industry data suggests that motors with a higher energy efficiency rating can reduce energy costs by approximately 30%, making them a cost-effective choice for long-term projects.

With a comprehensive grasp of these basic principles, project managers can make informed decisions that align with both their technical specifications and budgetary constraints, ultimately leading to the successful implementation of their projects.

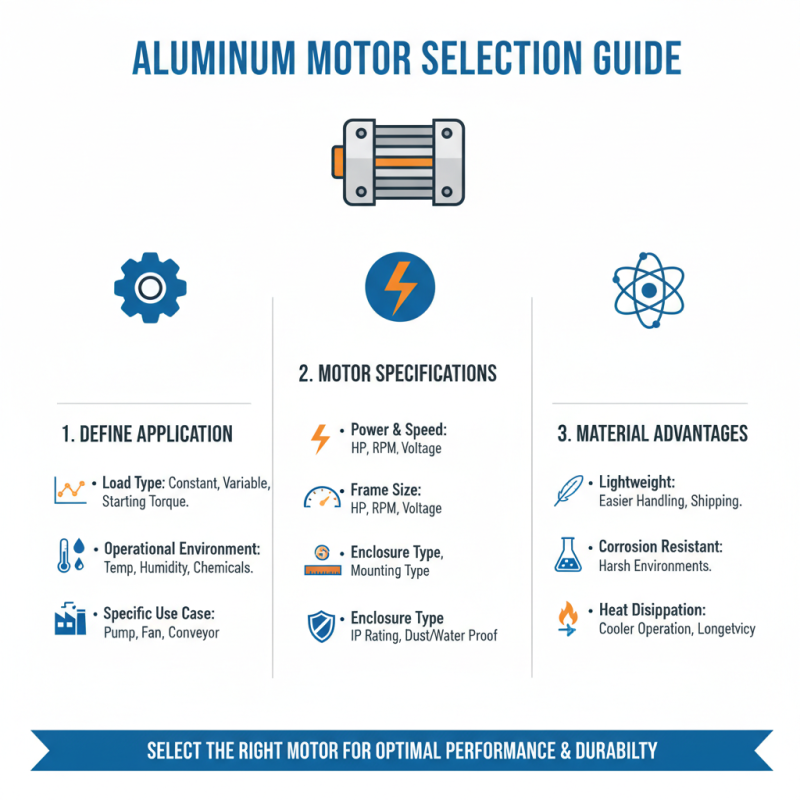

Assessing Your Project Requirements for Motor Selection

When selecting the appropriate aluminum motor for your project, assessing your project requirements is paramount. Start by defining the specific application for which the motor will be utilized. Understanding the type of load—whether it's constant, variable, or starting torque—will play a crucial role in determining the motor's specifications. Consider the operational environment as well, including factors such as temperature, humidity, and exposure to chemicals, which can influence the motor's performance and durability.

Another critical aspect to consider is the power requirements. Determining the voltage and current ratings needed for your project will help narrow down your options. Additionally, consider the efficiency and energy consumption of the motor, especially if the project demands prolonged operation. It’s also essential to evaluate the space constraints and mounting options; the physical dimensions of the aluminum motor should align with your design without compromising functionality. By carefully assessing these project requirements, you can ensure that the motor selected not only meets the technical demands but also enhances overall system performance.

Key Factors to Consider When Choosing an Aluminum Motor

When selecting the right aluminum motor for your project, several key factors should be considered to ensure optimal performance and longevity. First, it is essential to evaluate the required power output and torque specifications. Understanding the demands of your application will help you choose a motor that can effectively meet those requirements. Additionally, consider the operational environment, including temperature fluctuations, exposure to moisture, and potential contaminants. Aluminum motors often excel in environments where weight and corrosion resistance are significant factors, making them ideal for various industrial and outdoor applications.

Another important aspect to consider is the motor’s efficiency rating and energy consumption. An efficient motor can significantly reduce operational costs over time, making it a wise investment for long-term projects. Pay attention to the motor's speed settings and control options as well; flexibility in these areas allows for better integration into your existing systems. Finally, assess the motor’s mounting and design features to ensure compatibility with your project setup. Taking these factors into account will help you select the aluminum motor that best meets your specific needs and enhances your project's success.

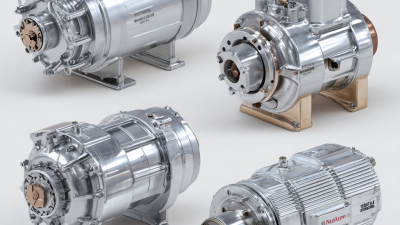

Comparing Different Types of Aluminum Motors Available

When selecting the right aluminum motor for your project, it's crucial to understand the various types available in the market. Aluminum motors are prized for their lightweight design, resistance to corrosion, and excellent heat dissipation. Most commonly, you will encounter induction motors, which operate efficiently and are suitable for continuous loading applications. They typically come in single-phase and three-phase options, with the three-phase models being preferred for industrial use due to their higher efficiency and power output.

Another type to consider is the brushless DC motor, which offers improved energy efficiency and lower maintenance requirements compared to traditional brushed motors. These motors are ideal for applications needing precise speed control and high starting torque. Furthermore, stepper motors are also worth examining, especially for projects that require accurate positioning and motion control. Each of these aluminum motor types serves distinct purposes and offers unique advantages, making it essential to assess the specific demands of your project before making a selection.

Tips for Sourcing and Purchasing Aluminum Motors Effectively

When sourcing and purchasing aluminum motors, it's essential to start by clearly defining your project's requirements. Consider factors such as the motor's power output, efficiency, and operating environment. Analyzing the specific applications can help ensure you select a motor that not only meets your performance criteria but also provides durability and longevity. Create a checklist that includes technical specifications, dimensions, and any unique features necessary for your application, as this will streamline the selection process.

Once you have your requirements outlined, research various suppliers and manufacturers. Look for companies with a solid reputation for quality and customer service. Check for certifications and compliance with industry standards, as these can indicate reliability and safety. Additionally, reviewing customer feedback and case studies can provide insights into the performance of their motors in real-world applications. Don’t hesitate to reach out to suppliers for quotes, availability, and any potential customizations you may require. Engaging in direct communication can also reveal valuable information about their products and help you establish a trustworthy partnership for your ongoing needs.

Aluminum Motor Specifications Comparison

This bar chart compares various aluminum motors based on their power output and weight. Selecting the right aluminum motor involves considering both the power requirements of your project and the weight constraints for effective performance.

Related Posts

-

The Ultimate Guide to Aluminum Motors Understanding Their Benefits and Applications in Modern Industry

-

2025 Top 5 Aluminum Motors: Boost Efficiency by 25% and Reduce Weight by 30%

-

Ultimate Guide to Selecting the Best Aluminum Motor for Global Procurement

-

What is an Aluminum Motor and Why is it Essential for Modern Machinery

-

Challenges Faced by Global Buyers in Sourcing Aluminum Body Motors

-

How to Select the Best Break Motor for Your Business Needs

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top