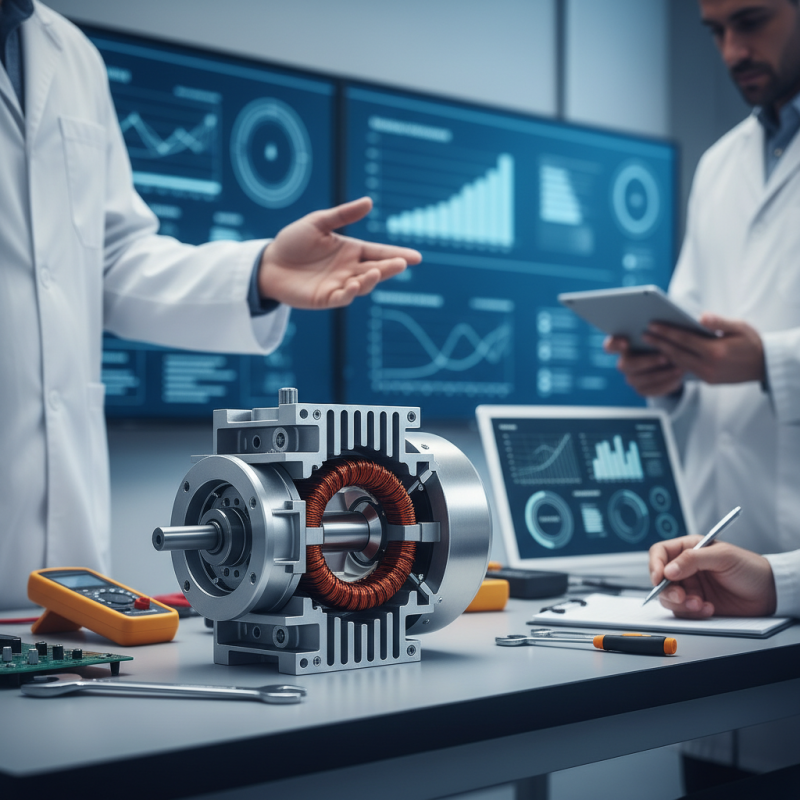

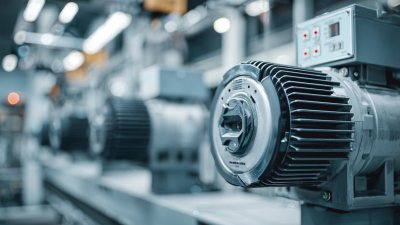

Inverter motors are becoming increasingly popular in various applications, both in industry and household settings. These motors are highly efficient and can operate at different speeds, making them versatile. In factories, they are often used in conveyor systems. The ability to adjust speed can improve production rates and reduce energy consumption. A slight delay in response might occur due to fluctuations in power supply, but this can often be mitigated with proper setup.

In residential settings, inverter motors are common in appliances like air conditioners and refrigerators. Their energy-saving capabilities can lead to lower electricity bills. However, if not chosen wisely, they may perform poorly under certain conditions. Noise levels can vary, and some models might be noisier than others. Users should consider this when making a selection.

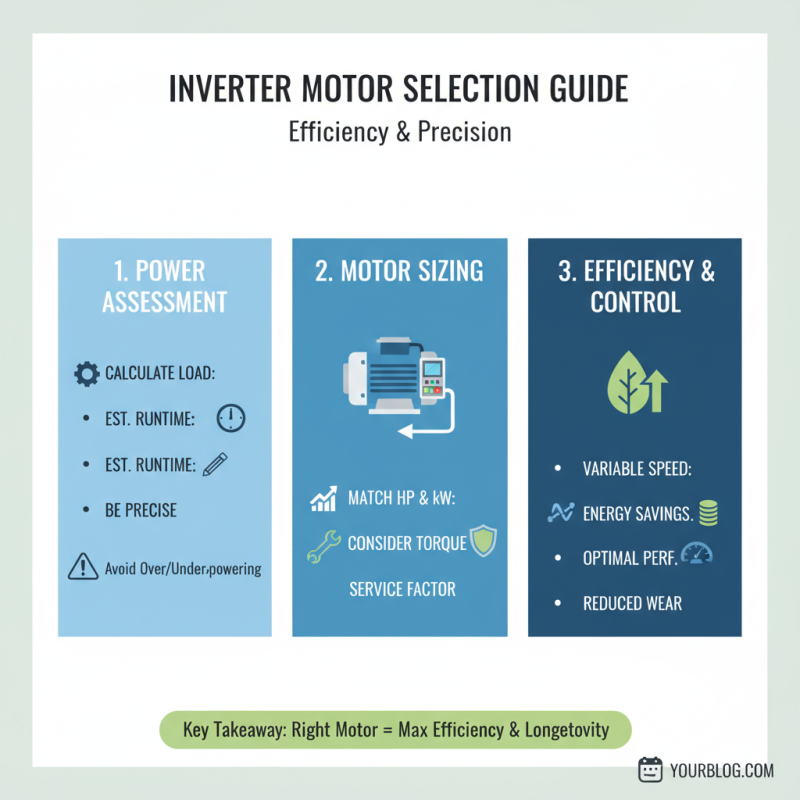

In addition, inverter motors can be used in pumps and fans for heating and cooling systems. They provide precise control over operation, which is essential for maintaining comfortable environments. Yet, improper installation may lead to inefficiencies. It is crucial to ensure that the right motor size is selected to avoid energy waste. Small adjustments can make a significant difference in effectiveness and performance.