Why Choose a Pump Motor for Your Industrial Applications?

In the ever-evolving industrial landscape, selecting the right equipment is crucial. One key component is the Pump Motor. According to the Market Research Future report, the global market for pump motors is projected to grow at a CAGR of 5.2% between 2021 and 2027. This growth reflects increasing industrial demands and the importance of efficiency in operations.

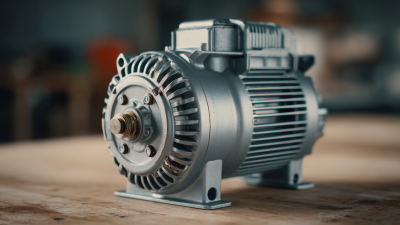

Many industries, from manufacturing to agriculture, rely on reliable pump motors. These devices convert electrical energy into mechanical energy, facilitating vital processes. However, selecting the proper pump motor requires careful consideration. Factors like energy efficiency, durability, and compatibility with existing systems play a significant role.

Yet, challenges persist. Not all motors meet the demands of various industries. Some may consume more energy than anticipated. Others may require frequent maintenance, leading to downtime. This illustrates the need for thorough evaluation when choosing a pump motor. Getting it wrong can affect productivity and costs.

Understanding the Basics of Pump Motors in Industrial Settings

Pump motors play an essential role in industrial settings. They are the heart of many systems, driving fluids through piping networks. Understanding how they function can enhance efficiency and reduce downtime. A pump motor converts electrical energy into mechanical energy. This energy is necessary for fluid movement, especially in large-scale operations.

Selecting the right pump motor requires an understanding of various factors. Horsepower, voltage, and service factor are crucial considerations. A mismatched motor can lead to inefficiency. For instance, a motor running under capacity may overheat, while an oversized one can waste energy. Proper sizing is vital to prevent these issues.

Regular maintenance can influence the longevity of pump motors. Inspecting seals, bearings, and wiring ensures smooth operation. Neglecting these aspects may lead to costly repairs. Workers should be trained to identify problems early. This proactive approach can save time and resources. In the fast-paced industrial environment, every second counts.

Why Choose a Pump Motor for Your Industrial Applications? - Understanding the Basics of Pump Motors in Industrial Settings

| Motor Type |

Horsepower (HP) |

Voltage (V) |

Efficiency (%) |

Application |

| Submersible Motor |

5 HP |

230V |

85% |

Water Management |

| Vertical Inline Motor |

10 HP |

460V |

90% |

HVAC Systems |

| Gear Motor |

2 HP |

230V |

88% |

Conveyor Systems |

| Trolley Motor |

1 HP |

115V |

86% |

Material Handling |

| Circulation Pump Motor |

3 HP |

230V |

92% |

Industrial Cooling |

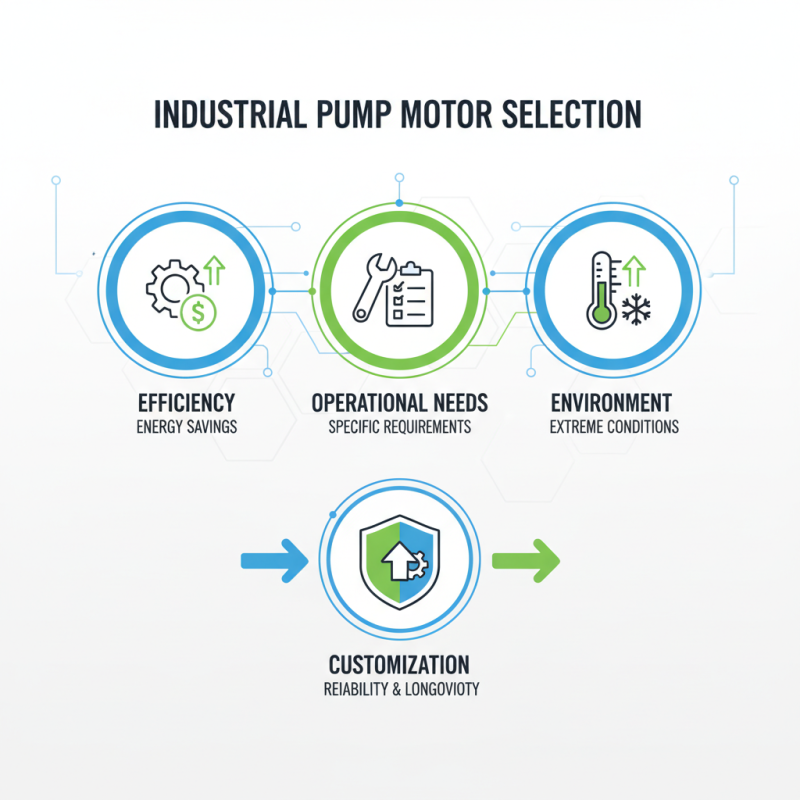

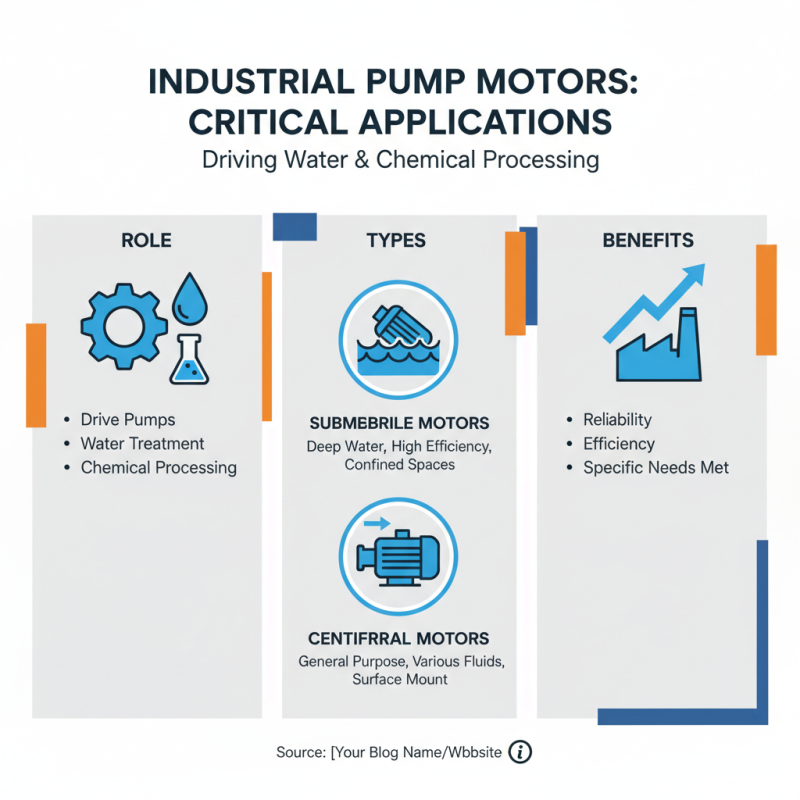

Types of Pump Motors and Their Industrial Applications

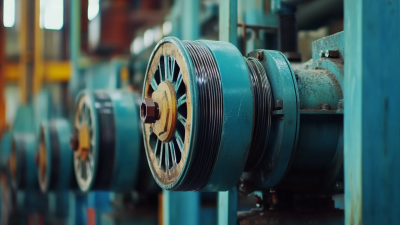

In industrial settings, pump motors play a critical role. They drive various applications, including water treatment and chemical processing. Different types of pump motors cater to specific needs. For example, submersible motors are vital for deep-water applications, offering high efficiency in confined spaces.

Data from the Industrial Motor Market Report shows that over 40% of industries rely on electric motors for operational efficiency. This heavy reliance highlights the importance of choosing the right motor type. Hydraulic pumps, driven by hydraulic motors, are preferred in heavy machinery. They provide robust power and reliability in harsh environments.

However, selecting a pump motor isn’t always straightforward. Miscalculating the motor size can lead to inefficiencies. Many industries report energy losses up to 30% due to mismatched components. It's essential to evaluate the specific application requirements carefully. Not every motor suits every task, and making an informed choice can improve overall energy savings and reduce operational costs.

Advantages of Using Pump Motors in Various Industries

Pump motors play a vital role in various industrial applications. Their efficiency and reliability make them essential in sectors like manufacturing, agriculture, and water treatment. By choosing the right pump motor, businesses can enhance productivity and streamline operations. These motors are designed to handle tough conditions, ensuring a steady flow of liquids.

One significant advantage of using pump motors is their energy efficiency. They can reduce operational costs considerably. Industries can benefit from lower electricity bills. Additionally, their durability leads to less frequent maintenance. This not only saves time but also minimizes unexpected downtime.

Tips: Assess the specific needs of your application. Match motor specifications to your system requirements. Regular maintenance checks can prevent issues before they arise. Consider upgrading older models to improve performance. A new motor can increase efficiency significantly. Reflect on whether your current setup meets your operational goals.

Advantages of Using Pump Motors in Various Industries

Maintenance and Efficiency Tips for Pump Motors

In industrial applications, pump motors play a crucial role. Proper maintenance greatly enhances their efficiency. According to a recent report by the U.S. Department of Energy, poorly maintained motors can be up to 10% less efficient. This inefficiency can lead to significant energy waste. Regular checks can help mitigate this problem.

Monitoring vibration levels is essential. Studies show that vibrations can increase maintenance costs by up to 20%. Implementing routine inspections can detect these issues early. Lubrication is another key factor. Over 30% of motor failures are due to inadequate lubrication. Simple practices, like using the right lubricants, can make a big difference.

However, many facilities overlook these basics. This negligence can result in unplanned downtime. Industry data suggests that unplanned outages can cost businesses millions each year. Emphasizing training for maintenance staff can close this gap. Investing in education is crucial to ensure your equipment runs smoothly and efficiently.