How to Choose the Right Gear Reducer for Optimal Efficiency: A Guide for Global Buyers

When it comes to enhancing the performance and efficiency of machinery, the selection of the right gear reducer is paramount. According to a recent report by MarketsandMarkets, the global gear reducer market is projected to reach USD 37.6 billion by 2025, driven by the growing need for energy-efficient solutions across various industries.

Gear reducers play a crucial role in reducing the speed of motors while increasing torque, thereby facilitating better control and efficiency in operations. As industries move towards automation and precision, understanding the benefits of different types of gear reducers becomes essential for global buyers. This guide will delve into the key considerations and advantages of selecting the appropriate gear reducer to ensure optimal performance and sustainability in your operations.

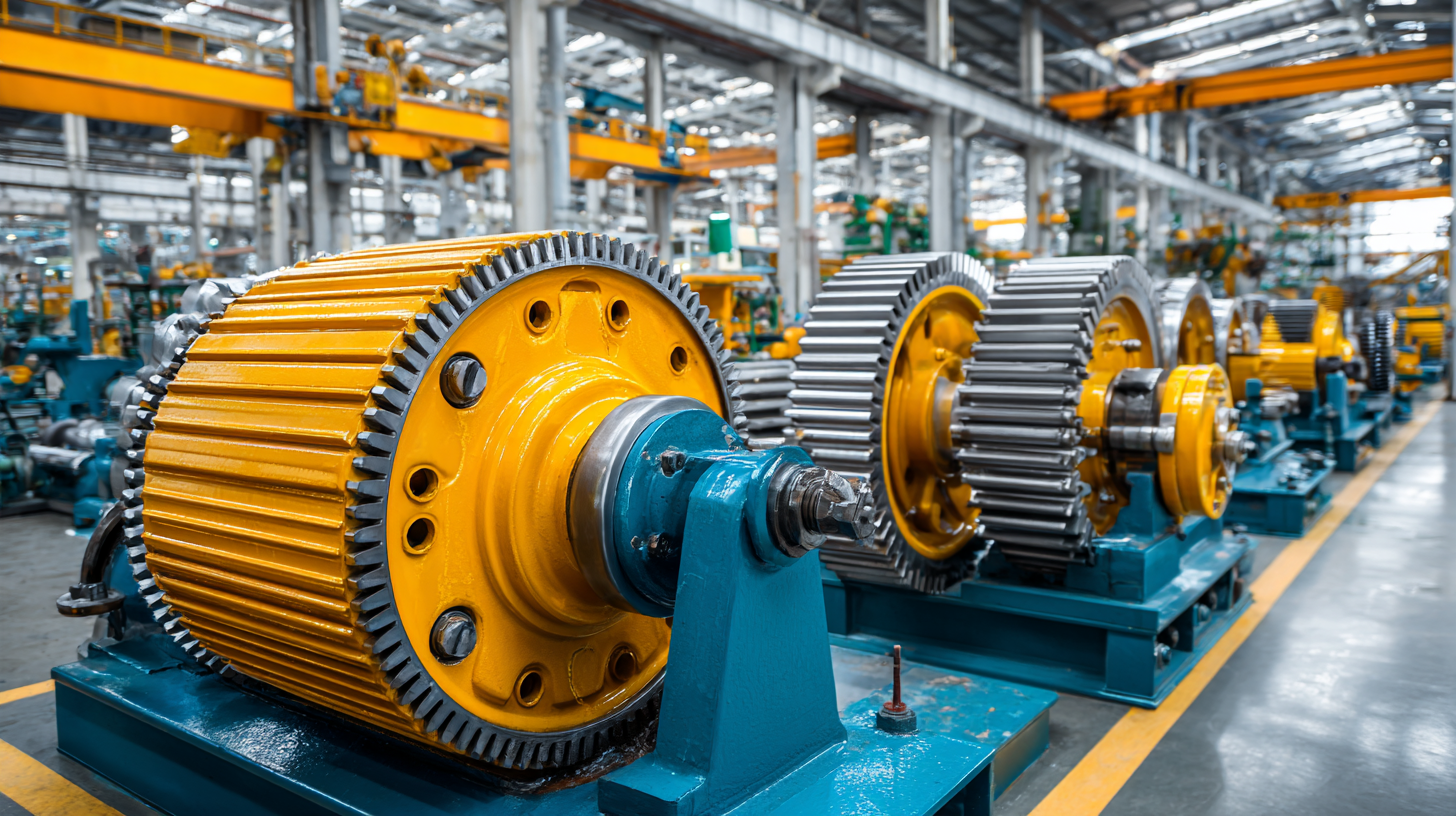

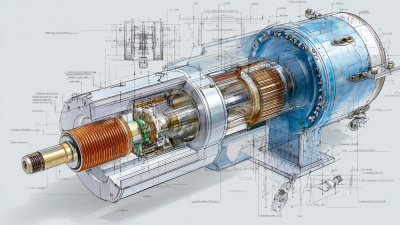

Understanding Gear Reducers: Types, Applications, and Efficiency Metrics

When selecting the right gear reducer, understanding the different types, applications, and efficiency metrics is paramount for global buyers. Gear reducers, often referred to as gearboxes, play a critical role in various industries by altering torque and rotational speed to meet specific operational requirements. According to recent industry reports, the global market for gear reducers is projected to grow at a CAGR of 5.2% from 2021 to 2026, driven by increased demand for energy-efficient systems in manufacturing and automation sectors.

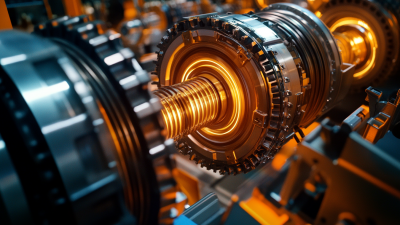

Different types of gear reducers serve distinct purposes: bevel, worm, and planetary gears, among others, each offering unique benefits in terms of size, weight, and efficiency. For instance, planetary gear reducers are renowned for their high torque density and compact design, making them ideal for space-constrained applications in robotics and electric vehicles. Efficiency metrics, such as service factor and efficiency ratings, are essential indicators of performance to evaluate, ensuring that the selected reducer meets the demands of its intended use. In real-world applications, optimizing these metrics can lead to a reduction in energy consumption of up to 20%, aligning with broader corporate sustainability goals and the reduction of greenhouse gas emissions. Monitoring performance through approaches akin to the Balanced Scorecard can also provide insights into the operational effectiveness of gear systems, enabling continuous improvement in productivity and efficiency.

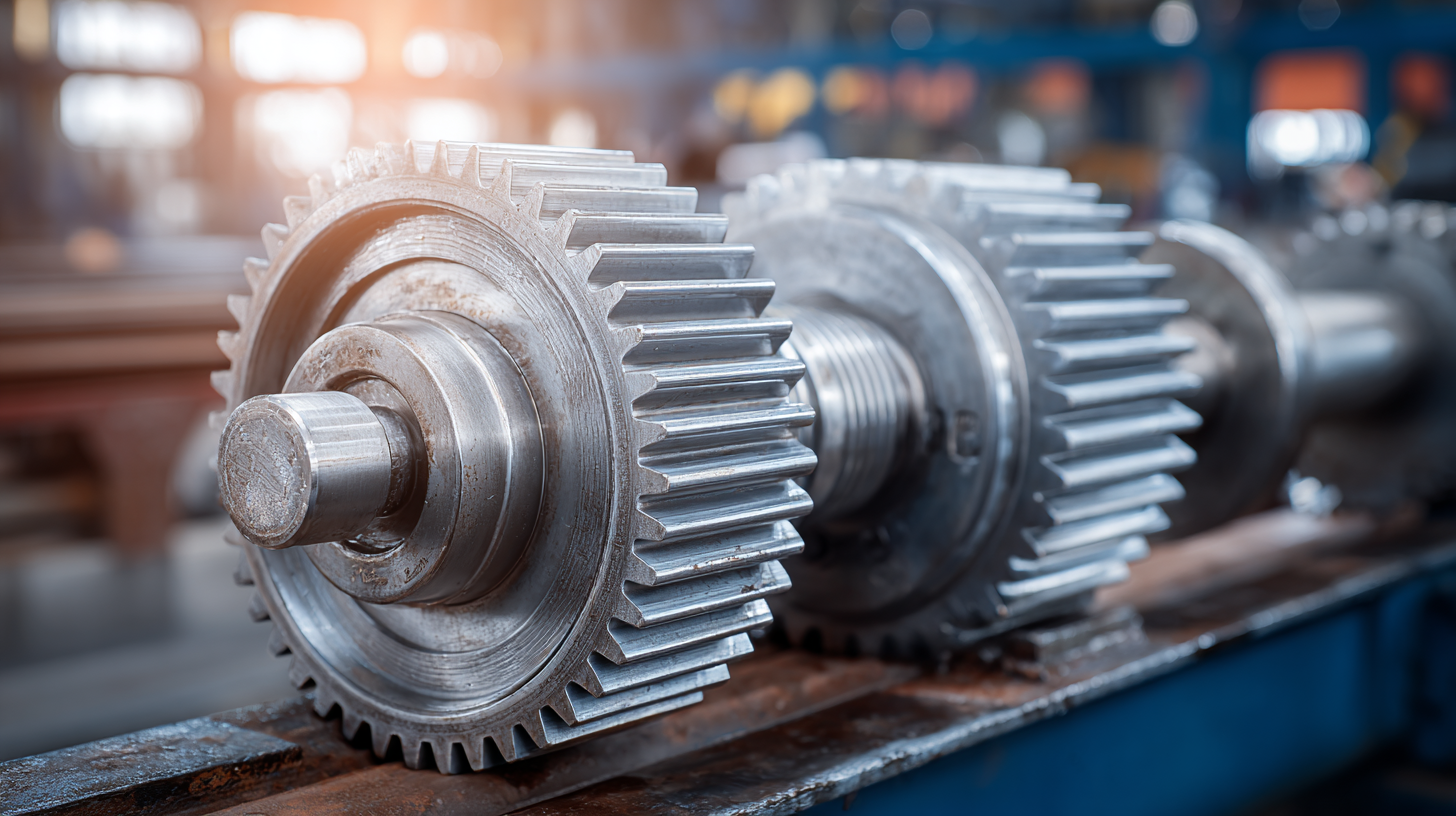

Key Factors in Selecting Gear Reducers: Load Capacity and Torque Requirements

When selecting a gear reducer, understanding load capacity and torque requirements is crucial for achieving optimal efficiency. Load capacity refers to the maximum weight or force that the gear reducer can handle without failure. This is determined by the materials used, design, and size of the gears. Buyers must evaluate the specific demands of their application—whether it's a heavy machinery operation or a precision task. A gear reducer with insufficient load capacity can lead to premature wear and operational failures, which can be costly in terms of repairs and downtime.

Torque requirements are equally important and often go hand-in-hand with load capacity. Torque is the rotational force generated by the gear reducer, and the required torque will vary depending on the operational conditions and the desired speed. When assessing torque needs, buyers should consider factors like acceleration, load variations, and environmental conditions. Calculating the right torque helps ensure that the gear reducer performs efficiently and meets the operational demands without overworking the system. By focusing on these key factors, global buyers can make informed decisions that enhance performance and sustainability in their operations.

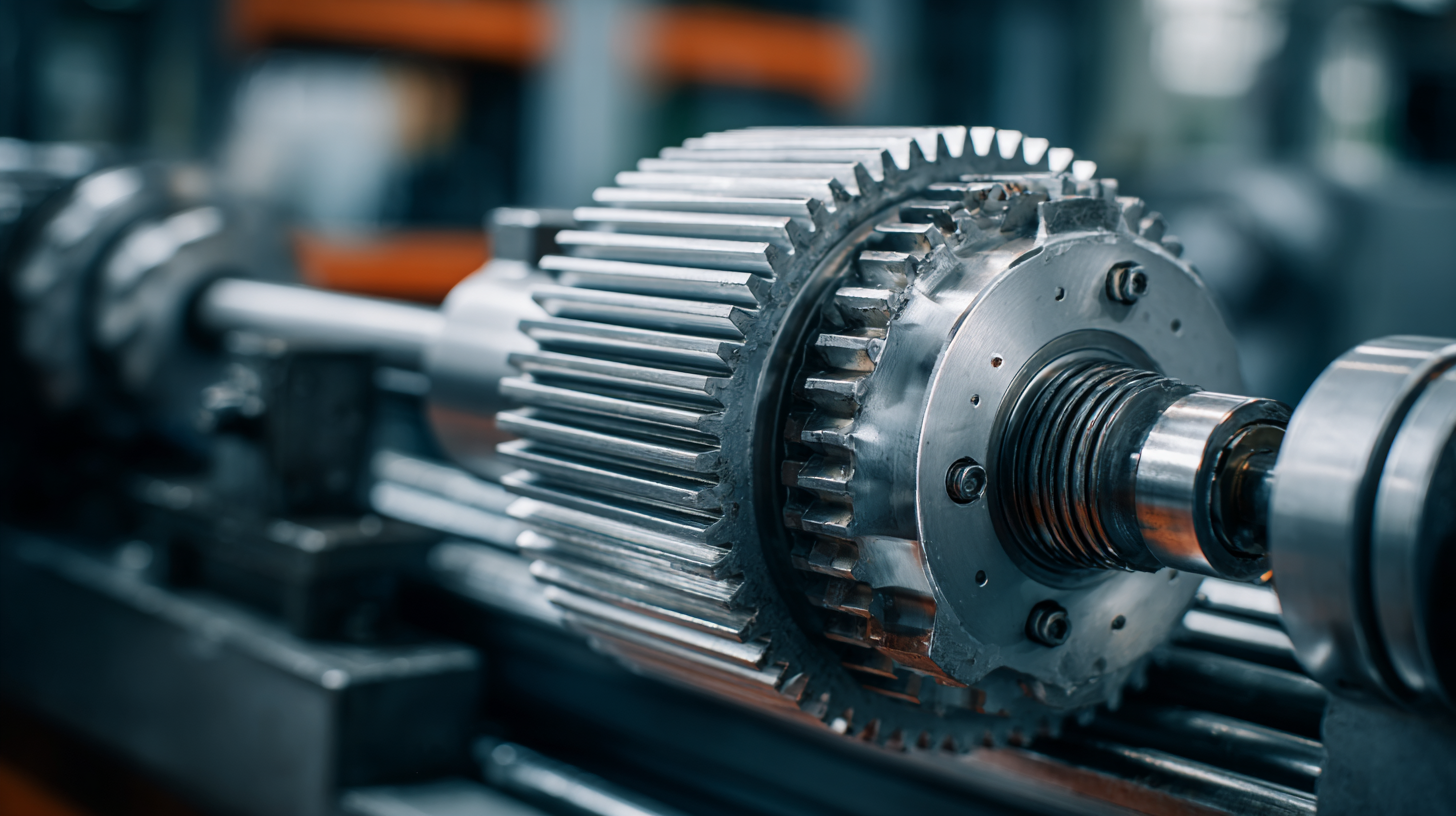

Evaluating Gear Reducer Efficiency: How to Interpret Efficiency Ratings

When evaluating gear reducer efficiency, understanding efficiency ratings is crucial for making informed purchasing decisions. Efficiency ratings are typically expressed as a percentage, representing the ratio of output power to input power. A higher efficiency rating indicates that a gear reducer is capable of converting more of the input energy into useful output, which directly impacts operational costs and energy consumption. Buyers should be aware that while a high efficiency rating is desirable, it often comes with a higher initial investment.

In addition to efficiency ratings, buyers must consider the specific application and operating conditions for the gear reducer. Factors such as load, speed, and environment can significantly influence the performance and longevity of a gear reducer. Reviewing manufacturer specifications and performance curves can provide deeper insight into how a gear reducer will perform under different circumstances. By correlating efficiency ratings with these operational factors, global buyers can select gear reducers that not only meet their efficiency needs but also ensure reliability and durability in their applications.

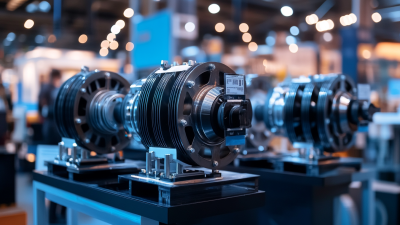

Global Market Trends for Gear Reducers: Insights from Recent Industry Reports

The global gear reducer market is witnessing significant growth, driven by advancements in technology and increased demand for efficient machinery across various sectors. According to the latest report from Research and Markets, the gear reducer market is expected to reach $4.5 billion by 2026, growing at a CAGR of 5.8% from 2021. This growth is particularly prominent in industries such as automotive, manufacturing, and renewable energy, where the need for high-performance equipment is paramount.

Another key insight from a recent Allied Market Research report highlights the rising trends in electric gear reducers, which are gaining traction due to their efficiency and environmental benefits. The demand for electric gear reducers is projected to grow by 7.5% annually as industries shift towards sustainable practices. Additionally, the increasing integration of automation technologies is prompting manufacturers to invest in advanced gear reduction solutions, ensuring better performance and reliability in their operations. As global buyers navigate this evolving landscape, understanding these trends will be crucial for selecting the right gear reducer to enhance operational efficiency and meet emerging demands.

Case Studies: Successful Gear Reducer Implementations in Various Industries

In the world of industrial applications, selecting the right gear reducer can significantly impact overall efficiency and productivity. Various industries have successfully implemented gear reducers tailored to their unique needs, demonstrating how crucial proper selection can be. For instance, in the automotive sector, manufacturers have utilized high-performance gear reducers to enhance the torque output of assembly robots, resulting in faster production cycles and reduced downtime.

When considering the implementation of gear reducers, it’s vital to analyze real-world case studies. In one notable example, a food processing plant upgraded to a gear reducer designed for high temperatures and hygiene standards. This change not only improved operational efficiency but also reduced maintenance costs due to its sturdy, corrosion-resistant design. Such success stories underline the importance of aligning gear reducer specifications with industry requirements.

Tips for Choosing Gear Reducers:

- 1. Evaluate the operating environment and select gear reducers that can withstand specific conditions, such as temperature, moisture, and exposure to chemicals.

- 2. Consider the gear ratio needed for your application, as it directly influences the speed and torque output, ensuring you achieve optimal performance.

- 3. Always consult with suppliers to understand the latest innovations and materials that can enhance efficiency and longevity in gear reducer systems.

Related Posts

-

Maximize Your Global Sourcing: Discover Cutting-Edge Centrifugal Pump Motors at the 2025 Canton Fair

-

Ultimate Guide to Selecting the Best Three Phase AC Motor for Your Industrial Needs

-

Maximize Efficiency with Exceptional After Sales Support for the Best Industrial Motor

-

Unlocking the Potential of Low Speed Motors for Efficient Global Supply Chains

-

Unveiling the Specifications of the Best AC Electric Motor: A Comprehensive Technical Review

-

Empowering Global Industries: Quality Frequency Converters from China's Leading Manufacturers

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top