How to Choose the Right Mining Motor for Your Operations

When it comes to mining operations, selecting the right mining motor is crucial for maximizing efficiency and productivity. Mining motors are the backbone of various equipment used in harsh environments, making their reliability and performance essential for operational success. With numerous types of motors available, each designed for specific tasks such as drilling, hauling, or crushing, the decision can often be overwhelming. Understanding the key factors that influence this choice, including power requirements, environmental conditions, and compatibility with existing machinery, is vital to making informed decisions. In this blog, we will guide you through the essential considerations in selecting the perfect mining motor to meet your operational needs, ensuring that your mining venture runs smoothly and effectively.

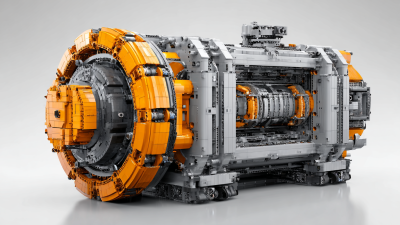

Understanding the Basics: Types of Mining Motors and Their Applications

When selecting a mining motor,

understanding the types and their applications is crucial for optimizing operational efficiency.

The primary types of mining motors include AC motors, DC motors, and high-efficiency specialty motors.

AC motors are widely used due to their robustness and low maintenance requirements, accounting for approximately 65% of the global mining motor market, as per a report by

MarketsandMarkets. These motors are ideal for applications involving constant speed and high torque, such as conveyor systems.

On the other hand,

DC motors, while comprising a smaller share of the market, are preferred in operations requiring

variable speed control, such as hoists and crushers. According to a recent study by

Frost & Sullivan, the demand for DC motors in the mining sector is expected to rise by 10% annually,

driven by advancements in control technology that enhance performance in challenging environments. Additionally, specialty motors,

including exploration-proof and submersible motors, are essential for specific applications, ensuring safety and reliability in hazardous conditions.

Understanding these nuances will guide operators in selecting the right motors to enhance productivity and ensure worker safety in mining operations.

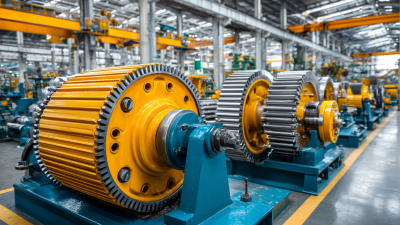

Evaluating Power Requirements: How to Match Motor Ratings to Mining Equipment Needs

Choosing the appropriate mining motor is crucial for optimizing operational efficiency and ensuring equipment longevity. Evaluating power requirements begins with understanding the specific energy demands of your mining equipment. According to the International Energy Agency, mining operations account for approximately 11% of global energy consumption, highlighting the importance of aligning motor ratings with operational needs to enhance energy efficiency. Selecting a motor that accurately matches the load characteristics not only prevents energy wastage but also reduces mechanical strain, prolonging the lifespan of the equipment.

To effectively match motor ratings to mining equipment needs, operators should consider both the starting and continuous power requirements. The 2021 Mining Equipment Market Analysis indicated that improperly sized motors can lead to energy losses of up to 30% during operation. By employing predictive maintenance tools and load analysis software, mining companies can gather necessary data to identify peak loads and select motors with appropriate torque and power ratings. This approach enables more precise matching of motors to equipment, leading to improved performance and reduced operational costs in the long run.

Assessing Efficiency: The Impact of Motor Performance on Operational Costs

When selecting a mining motor, understanding how motor performance influences operational costs is critical. Efficiency ratings, such as the motor's Full Load Efficiency (FLE), determine how much energy is converted into productive work versus wasted as heat. According to a recent report by the International Energy Agency (IEA), optimizing motor performance can reduce energy consumption by up to 30% in industrial applications. In the context of mining, where energy costs often represent a significant portion of operating expenses, even minor improvements in efficiency can translate into substantial savings.

Furthermore, the choice of a high-efficiency motor can have cascading benefits beyond just energy savings. Advanced motors typically come equipped with better cooling systems and lower maintenance requirements, which extend their operational lifespan. A study by the U.S. Department of Energy indicates that improved motor design can lead to reduced overall maintenance costs by up to 20%. For mining operations striving to lower operational costs while maximizing productivity, investing in the right mining motor is not just a choice; it’s a strategic imperative that affects the bottom line over both the short and long term.

Environmental Considerations: Selecting Motors with Sustainable Practices in Mind

In today’s mining industry, selecting motors with environmental sustainability in mind is more crucial than ever. According to a report by the International Energy Agency, mining operations account for nearly 10% of global energy consumption, with a significant portion attributed to electric motors. Choosing energy-efficient motors can drastically reduce this consumption, thus minimizing the carbon footprint of operations.

Tip: When selecting a motor, consider models that comply with ISO 50001 energy management standards. These motors not only enhance efficiency but also provide substantial cost savings in the long run through lower energy expenses.

Furthermore, look for motors that utilize sustainable materials and manufacturing processes. A study conducted by the Mineral Council of Australia highlighted that sourcing motors made from recycled or eco-friendly materials can lead to a reduction in resource extraction and pollution. This aligns mining practices with increasing regulatory pressures and community expectations regarding environmental stewardship.

Tip: Investigate suppliers who prioritize sustainability in their production, as these partnerships can enhance your own operational responsibilities while benefiting the planet.

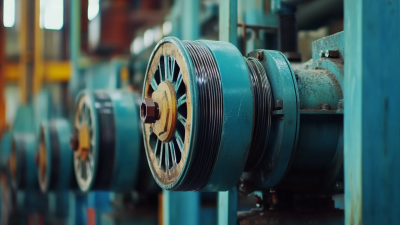

Maintenance and Longevity: Key Features to Look for in Reliable Mining Motors

When selecting a mining motor, maintenance and longevity stand out as crucial factors that directly impact operational efficiency and cost-effectiveness. According to a recent report published by the International Mining Association, nearly 30% of unplanned downtimes in mining operations are attributed to motor failures caused by inadequate maintenance practices. To mitigate this risk, operators should prioritize motors with features designed for durability, such as robust enclosures that protect against dust and moisture, as well as high insulation ratings to withstand harsh environmental conditions.

When selecting a mining motor, maintenance and longevity stand out as crucial factors that directly impact operational efficiency and cost-effectiveness. According to a recent report published by the International Mining Association, nearly 30% of unplanned downtimes in mining operations are attributed to motor failures caused by inadequate maintenance practices. To mitigate this risk, operators should prioritize motors with features designed for durability, such as robust enclosures that protect against dust and moisture, as well as high insulation ratings to withstand harsh environmental conditions.

Another essential aspect to consider is the efficiency rating of the motor. The U.S. Department of Energy notes that high-efficiency motors can reduce energy consumption by up to 10%, leading to significant cost savings over time. Additionally, look for motors with built-in monitoring systems that allow for real-time performance tracking, enabling proactive maintenance before minor issues escalate into major failures. Investing in motors with these key features not only enhances the longevity of your equipment but also contributes to a more sustainable operation by minimizing energy waste and unplanned downtimes.

Related Posts

-

Crafting Excellence with Chinese Manufacturing Bringing the Best Mining Motor to the Global Market

-

The Pride of China Delivering Best Break Electric Motors to the World

-

Real World Applications of Best Industrial Motors in Different Industries

-

Empowering Your Operations: Discovering Benefits of 3ph Electric Motors for Global Sourcing

-

How to Choose the Right Gear Reducer for Optimal Efficiency: A Guide for Global Buyers

-

Future Trends in the Best Iron Body Motor Market Towards 2025

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top