2026 How to Choose the Right Centrifugal Pump Motor for Your Needs?

Choosing the right centrifugal pump motor is crucial for effective operation. A well-suited motor can enhance efficiency and reliability. However, with various options available, the selection process may feel overwhelming.

Understanding your needs is key. Identify the pump's required flow rate, pressure, and application. Ensure that the centrifugal pump motor matches these specifications closely. Consider factors like power source and motor speed. The type of fluid being pumped is also important. It affects the motor's material compatibility and performance.

Don't overlook energy efficiency. An efficient motor saves costs in the long run. Evaluate initial costs and long-term expenses. While it’s tempting to choose cheaper options, often they lead to higher maintenance needs. Reflect on your specific circumstances. Balancing performance, cost, and efficiency may not be easy, but it’s essential for optimal results.

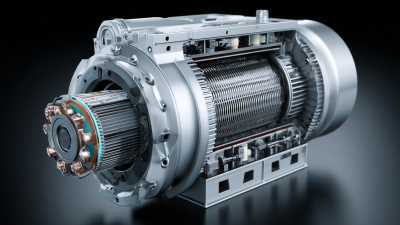

Understanding Centrifugal Pump Motors: An Overview

Centrifugal pump motors are crucial in various industries, ensuring the efficient movement of fluids. Understanding these motors can help you select the best option for your needs. A recent industry report highlighted that centrifugal pumps account for nearly 60% of all pumps used worldwide, emphasizing their significance.

These motors operate by converting electrical energy into mechanical energy. They need to match the pump's requirements for optimal performance. When selecting a motor, consider factors like flow rate and horsepower. Data shows that selecting the right horsepower can improve efficiency by up to 20%. It’s essential to review the power supply and operational environment as well.

Energy efficiency is another significant aspect. Inefficient motors can cause energy losses. A study found that poorly matched motors lead to 15% energy losses. When choosing a centrifugal pump motor, ensure it can deliver consistent performance under varying conditions. Not all motors perform equally, and some may not fit specific applications, leading to operational challenges.

Key Factors to Consider When Choosing a Motor

Choosing the right motor for a centrifugal pump can be challenging. Start by considering the pump's application. Different applications require different motor specifications to achieve optimal performance. For instance, if the pump is intended for water or chemicals, the motor's materials should resist corrosion.

Next, evaluate the power requirements. Calculate the necessary horsepower based on the pump's flow and Head pressure. A common mistake is underestimating these needs, which can lead to efficiency losses. Take note of the motor's efficiency rating as well; a higher efficiency means lower energy costs over time.

Lastly, think about environmental conditions. Will the motor operate in extreme temperatures or dusty environments? Motors designed for harsh conditions can be more expensive. Reflect on your budget versus the longevity you expect. While saving costs is tempting, investing in a suitable motor may save more in maintenance and replacement.

2026 How to Choose the Right Centrifugal Pump Motor for Your Needs?

| Factor | Description | Considerations |

|---|---|---|

| Power Rating | The power the motor can deliver to the pump. | Select based on pump flow requirements and system head. |

| Efficiency | The ratio of useful output power to the power input. | Higher efficiency can lead to lower operating costs. |

| Voltage Rating | The voltage at which the motor operates. | Match with available power supply. |

| Service Factor | The motor's ability to handle overload conditions. | A higher service factor indicates greater durability. |

| Cooling Method | The way the motor dissipates heat. | Consider ambient conditions and installation location. |

| Starting Method | How the motor is started (e.g. direct on-line, star-delta). | Select based on application needs and available equipment. |

| Noise Level | The sound emitted by the motor during operation. | Important for applications in noise-sensitive environments. |

| Environmental Protection | The degree to which the motor can resist harsh conditions. | Look for IP ratings for dust and moisture protection. |

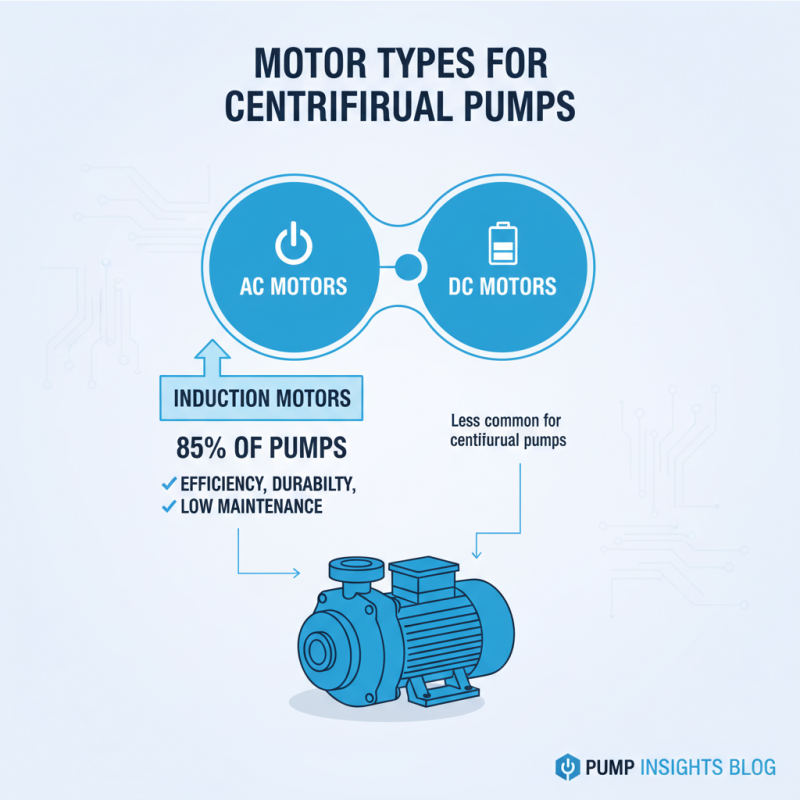

Types of Motors Suitable for Centrifugal Pumps

When selecting a motor for centrifugal pumps, understanding motor types is crucial. There are primarily two categories: AC and DC motors. AC motors, particularly induction motors, are widely used due to their efficiency. According to industry reports, over 85% of centrifugal pumps utilize AC induction motors. These motors are known for their durability and low maintenance needs.

DC motors offer higher torque and better speed control. However, they are less common in large centrifugal systems. A significant factor to consider is the environment. For instance, explosion-proof motors are essential for hazardous areas. Adjusting pump performance may also require variable frequency drives (VFDs). VFDs help optimize energy use and extend motor lifespan by reducing wear.

Additionally, the motor size must match the pump's requirements. If not properly sized, inefficiencies arise. An oversized motor consumes unnecessary energy. Conversely, an undersized motor risks failure and overheating. Getting this balance right is often challenging. Some installations ignore these details, leading to increased costs and downtime. Understanding these aspects can significantly impact both efficiency and reliability in centrifugal pump operations.

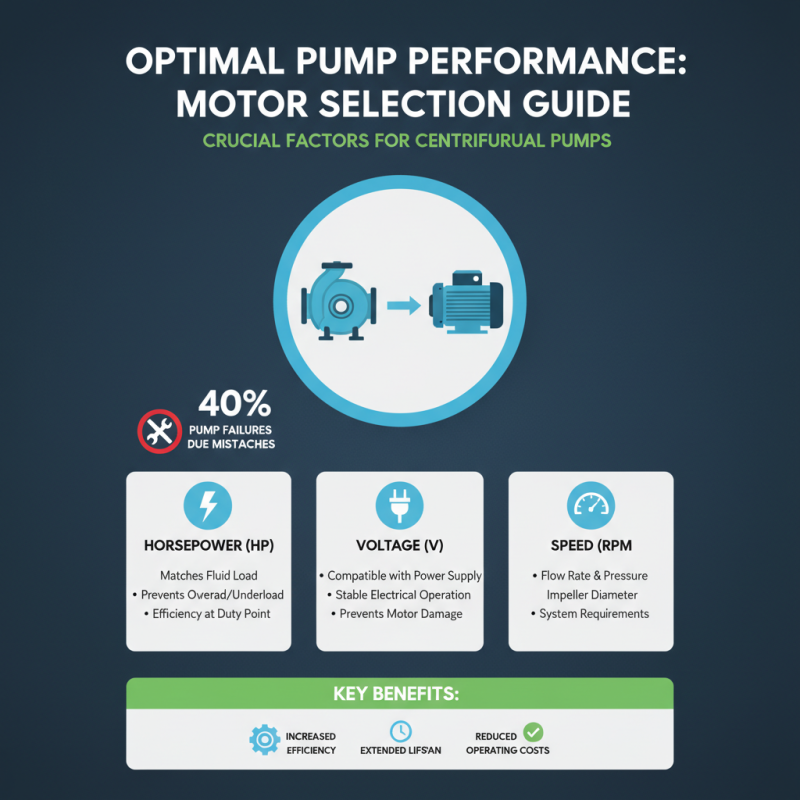

Matching Motor Specifications to Pump Requirements

Choosing the right motor for your centrifugal pump is crucial. It impacts efficiency, operation, and longevity. Motor specifications must align with pump requirements. Key specifications include horsepower, voltage, and speed. According to industry reports, approximately 40% of pump failures relate to matching issues.

Understanding the pump’s flow rate and head requirements will guide motor selection. If the pump retracts against high pressure, ensure the motor delivers adequate torque. A mismatch may lead to premature wear and inefficient operation. Industry data suggests that a properly matched motor can improve efficiency by 20%, leading to significant energy cost savings.

Tips: Always consult performance curves for the pump and motor. They help visualize the relationship between speed and head. Monitor the pump’s service conditions as well. If it operates in extreme temperatures, choose a motor rated for those conditions. Regular checks are crucial. Ignoring slight inefficiencies can lead to major problems down the line.

Maintenance Tips for Centrifugal Pump Motors

Maintaining centrifugal pump motors is crucial for optimal performance. Regular checks can help identify wear and tear issues early. Don't wait for a breakdown to address potential problems. Listening for unusual noises can indicate motor stress. Inspecting connections is also important. Loose wires can lead to severe malfunctions.

Lubrication is another vital aspect of maintenance. Ensure that bearings are properly greased. Over-greasing can cause more harm than good, leading to overheating. Check the motor’s cooling system regularly. Dust and debris can accumulate, obstructing airflow. This may reduce efficiency and lifespan.

Routine cleaning is essential, but it’s easy to overlook. Regularly remove dust and dirt from the motor housing. Neglecting this can lead to rust and corrosion. Also, consider the environment. Motors in dusty or damp locations require more frequent attention. Reflect on your maintenance schedule. Is it truly sufficient for the conditions in which the motor operates?

Comparison of Centrifugal Pump Motor Efficiency Ratings

This bar chart illustrates the efficiency ratings of various types of centrifugal pump motors. Understanding the efficiency can help you choose the right motor for your needs, particularly in terms of energy consumption and operational cost.

Related Posts

-

Maximize Your Global Sourcing: Discover Cutting-Edge Centrifugal Pump Motors at the 2025 Canton Fair

-

Understanding the Power: How Centrifugal Pump Motors Enhance Industrial Efficiency

-

Future Trends in the Best Iron Body Motor Market Towards 2025

-

How to Choose the Right Centrifugal Pump Motor for Your Applications

-

2025 Top 5 Aluminum Motors: Boost Efficiency by 25% and Reduce Weight by 30%

-

Quality Induction Motors Made in China Setting New Standards for Global Procurement

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top