How to Choose the Right Air Compressor Motor for Your Needs

When selecting the right Air Compressor Motor, it's essential to consider various factors that align with your specific operational needs. According to a recent industry report by Grand View Research, the global air compressor market is projected to reach USD 40.4 billion by 2025, highlighting the growing demand for efficient and reliable pneumatic power solutions across various sectors.

Choosing the right motor type, size, and efficiency rating can significantly impact your compressor's performance, energy consumption, and overall cost-effectiveness. With advancements in technology, electric motors, especially those with variable frequency drives (VFDs), have gained popularity for their ability to optimize energy usage and reduce operational costs. A comprehensive understanding of these elements will enable you to make an informed decision that enhances productivity while maintaining the reliability necessary for your applications.

Choosing the right motor type, size, and efficiency rating can significantly impact your compressor's performance, energy consumption, and overall cost-effectiveness. With advancements in technology, electric motors, especially those with variable frequency drives (VFDs), have gained popularity for their ability to optimize energy usage and reduce operational costs. A comprehensive understanding of these elements will enable you to make an informed decision that enhances productivity while maintaining the reliability necessary for your applications.

Understanding Different Types of Air Compressor Motors

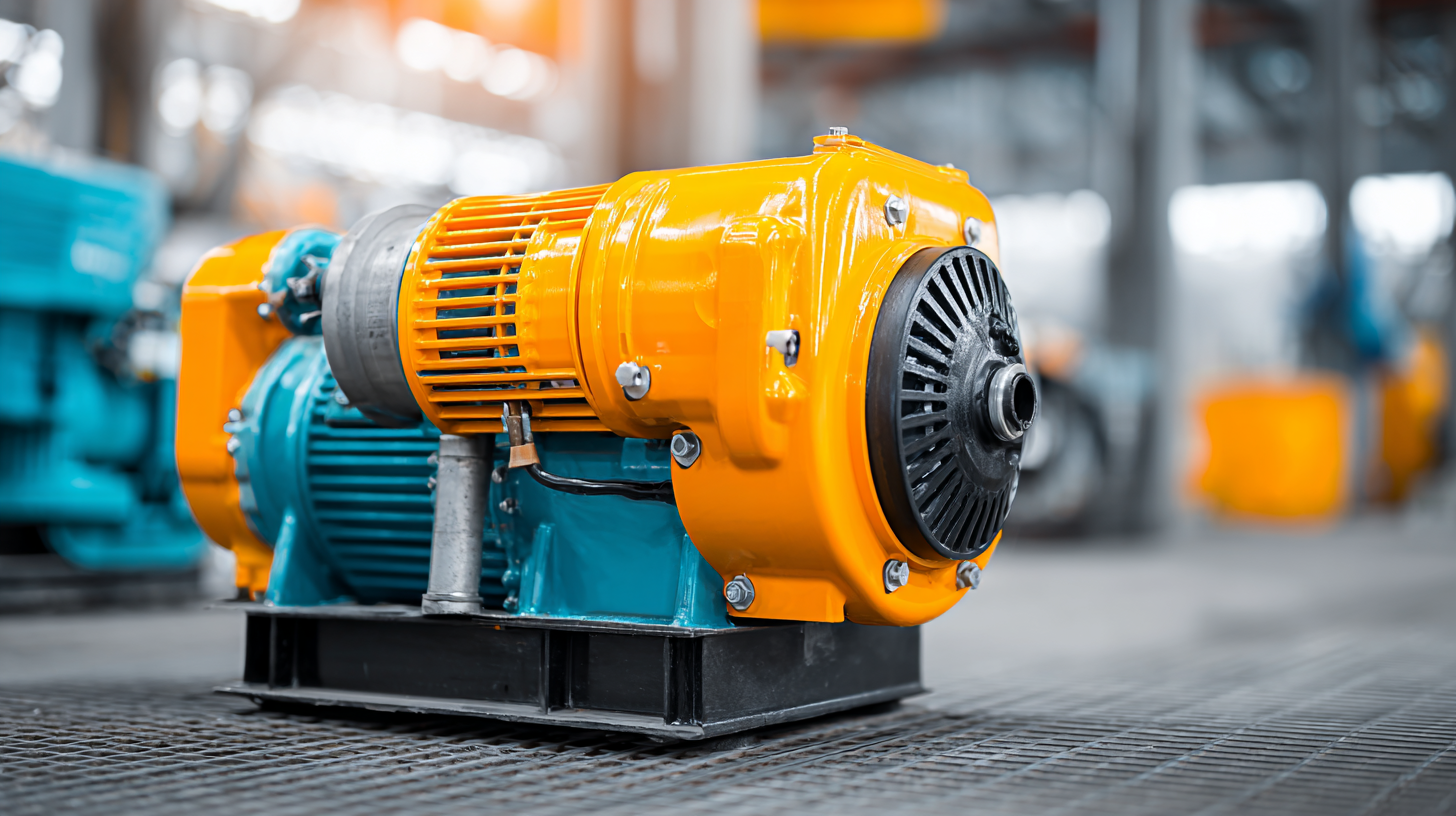

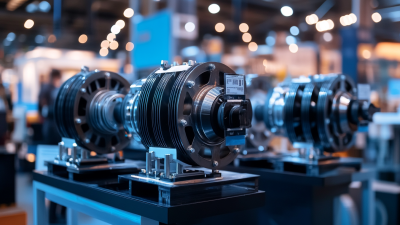

When selecting the right motor for your air compressor, it's essential to understand the different types of motors available and their specific applications. The two main categories of motors are electric and gasoline-powered. Electric motors are the most common choice for stationary applications, offering efficiency and ease of use, while gasoline-powered motors provide mobility and are suitable for portable compressors used in construction or outdoor settings.

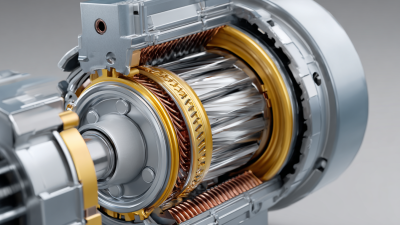

Within the electric motor category, there are two primary types: induction motors and brushless motors. Induction motors are robust and reliable, making them ideal for continuous operation. They are typically less expensive and require minimal maintenance. On the other hand, brushless motors are known for their higher efficiency and longer lifespan. They generate less heat and can handle variable load conditions better than their brushed counterparts, making them a superior choice for applications requiring precision and energy conservation. Understanding these differences will help you choose a motor that aligns with your compressor's intended use and operational demands.

How to Choose the Right Air Compressor Motor for Your Needs - Understanding Different Types of Air Compressor Motors

| Motor Type | Power Source | Efficiency Rating | Typical Applications | Horsepower (HP) |

|---|---|---|---|---|

| Induction Motor | Electric | High | Commercial & Industrial | 5 - 25 HP |

| Universal Motor | Electric (AC/DC) | Medium | Portable Air Compressors | 0.5 - 3 HP |

| Brushless DC Motor | Battery/Electric | Very High | Cordless Tools | 1 - 5 HP |

| Single Stage Reciprocating Compressor | Electric/Gas | Medium | DIY & Home Use | 1 - 10 HP |

| Two Stage Reciprocating Compressor | Electric/Gas | High | Industrial & Heavy Duty | 5 - 30 HP |

Assessing Power Requirements for Your Air Compressor Applications

When selecting the right air compressor motor, it's crucial to assess the power requirements specific to your applications. Different tasks such as spray painting, pneumatic tool operation, or inflating tires demand varying levels of horsepower and efficiency. Start by determining the CFM (cubic feet per minute) and PSI (pounds per square inch) needed for your project. This will help guide you in choosing a motor that can deliver the appropriate pressure and volume.

Tip: Always consider the duty cycle of your compressor. If you anticipate running the compressor for extended periods, opting for a motor with a higher horsepower and robust design will prevent overheating and ensure consistent performance.

Additionally, think about the power source. Electric motors are generally quieter and easier to maintain, while gas engines provide portability for outdoor tasks. Assess your workspace and determine which motor type aligns with your operational needs.

Tip: Ensure you factor in the voltage supply available, as selecting a motor that exceeds your electrical system's capability can lead to operational issues and potential safety hazards.

Evaluating Efficiency Ratings and Energy Consumption

When selecting an air compressor motor, evaluating efficiency ratings and energy consumption is critical for ensuring optimal performance and cost-effectiveness. Efficiency ratings, often represented as a percentage, indicate how effectively the motor converts electrical energy into mechanical energy. Higher efficiency ratings mean that more power is effectively utilized, thereby reducing operational costs and energy waste. It is advisable to choose motors that meet or exceed industry standards, such as those set by the Department of Energy, for enhanced performance and sustainability.

Additionally, energy consumption plays a significant role in the long-term viability of an air compressor system. Look for motors equipped with advanced technologies such as variable speed drives, which adjust the motor's power output based on workload demands. This adaptability can significantly lower energy usage during lighter tasks. Remember to assess the motor's duty cycle and peak load capabilities, as these factors will further influence energy consumption and operational efficiency. By thoroughly evaluating these parameters, you can select an air compressor motor that not only meets your immediate needs but also promotes energy efficiency and longevity.

Choosing the Right Motor Size and Horsepower for Your Needs

When selecting the right air compressor motor, determining the appropriate motor size and horsepower is crucial to meet your specific needs. According to industry reports, air compressors typically require motors ranging from 1 to 30 horsepower, depending on the intended application. For light-duty tasks such as inflating tires or powering small tools, a 1 to 5 horsepower motor suffices. However, for heavy-duty applications in industrial settings, motors exceeding 10 horsepower may be necessary to ensure efficiency and reliability.

Tips: Always calculate the required airflow in cubic feet per minute (CFM) and pressure in pounds per square inch (PSI) for your applications. This will help prevent underperformance. For instance, a motor with 5 horsepower can generally deliver about 17 CFM at 90 PSI, making it suitable for moderate applications. Always consider a motor slightly larger than your calculated need to accommodate any unexpected demands.

Choosing the right motor size not only impacts performance but also energy efficiency. According to the Department of Energy, properly sized motors can yield up to 15% savings in energy use. Furthermore, maintaining the motor's operational efficiency through regular inspections and service can prolong its lifespan, thus contributing to cost savings over time.

Considering Noise Levels and Maintenance Needs in Motor Selection

When selecting the right air compressor motor, it's crucial to consider noise levels alongside maintenance needs. Noise can significantly affect work environments, especially in industries where quiet operation is paramount. According to industry data, noise levels above 85 dBA may not only disrupt productivity but also pose health risks to employees over prolonged exposure. Therefore, opting for motors designed to operate at lower decibel levels can enhance workplace comfort while ensuring compliance with safety regulations.

Maintenance needs are another key factor to weigh in motor selection. A study from the HVAC sector indicates that advanced motors with integrated smart technology can reduce maintenance frequency by up to 30%. These motors often come equipped with sensors that monitor performance and alert users to potential issues before they escalate. This predictive maintenance capability can lead to significant cost savings and extended motor lifespan, reducing downtime and contributing to overall operational efficiency in environments where reliability is critical.

Related Posts

-

10 Reasons Why the Best AC Motors Outperform Competitors in Efficiency and Longevity

-

Future of Manufacturing: A Comprehensive Guide to Best Iron Body Motors in 2025 Trends

-

Exploring Innovative Applications of Induction Motors Across Different Industries

-

Solutions for Outstanding Performance in Asynchronous Motors

-

How to Choose the Right Gearbox Motor for Your Application

-

Maximize Your Global Sourcing: Discover Cutting-Edge Centrifugal Pump Motors at the 2025 Canton Fair

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top