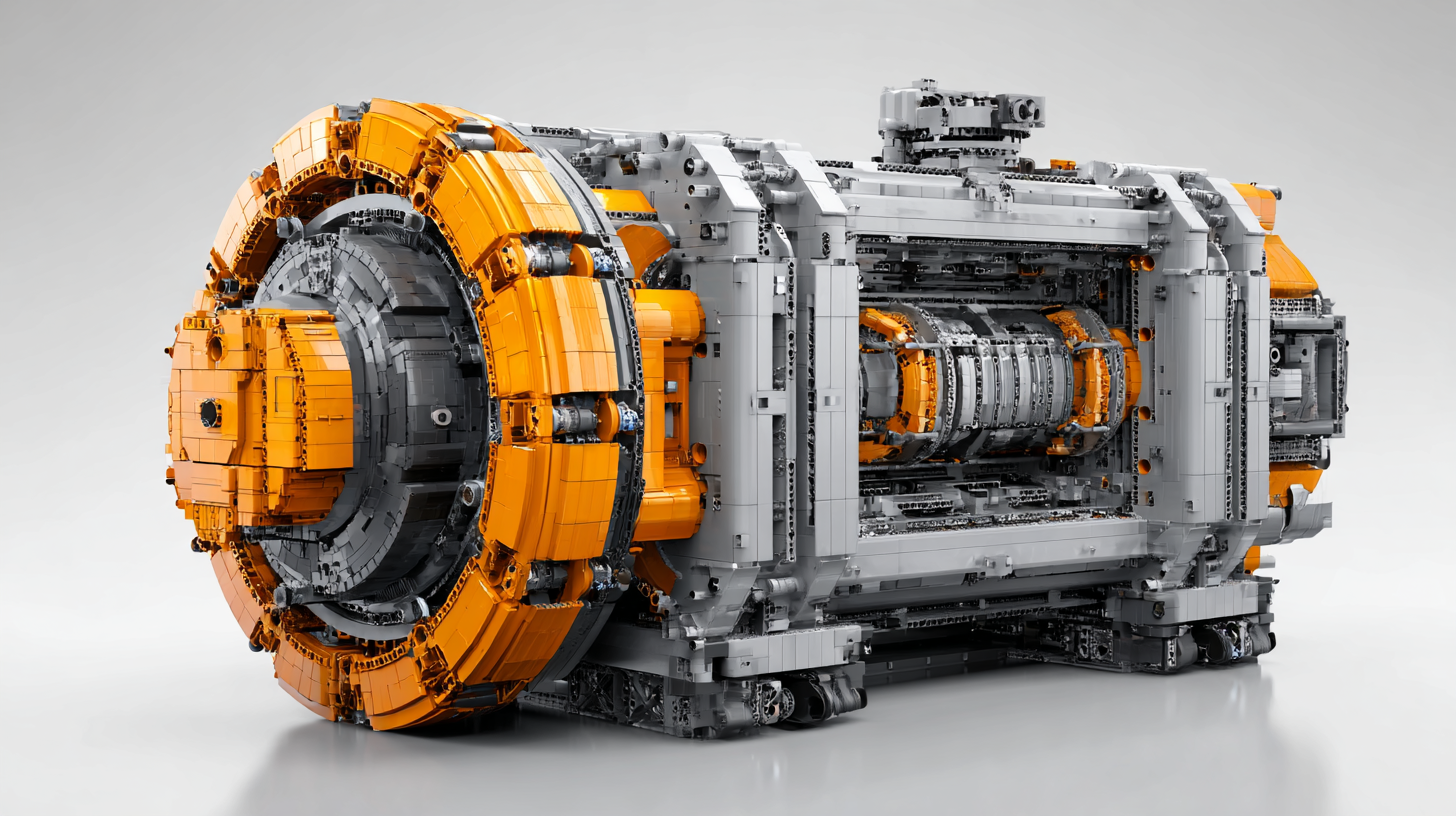

Crafting Excellence with Chinese Manufacturing Bringing the Best Mining Motor to the Global Market

In the ever-evolving landscape of industrial machinery, the significance of quality manufacturing cannot be overstated, particularly when it comes to the production of specialized equipment like Mining Motors. As the backbone of the mining industry, these motors play a crucial role in ensuring efficiency, reliability, and safety in various operations. This blog explores how Chinese manufacturing has positioned itself as a leader in crafting exceptional Mining Motors that not only meet but exceed global standards. By leveraging advanced technology, skilled craftsmanship, and stringent quality control, manufacturers in China are enhancing the operational capabilities of mining enterprises worldwide. Join us as we delve into the intricacies of this manufacturing excellence and highlight the key features that make these Mining Motors a preferred choice for global markets.

The Rise of Chinese Manufacturing in the Global Mining Sector

The global mining sector has witnessed a significant transformation in recent years, with Chinese manufacturing emerging as a pivotal player in this increasingly competitive landscape. With advancements in technology and a focus on quality, Chinese manufacturers have redefined the standards of mining equipment, particularly in motor production. These innovations not only enhance operational efficiency but also reduce downtime, ultimately leading to increased productivity for mining companies worldwide.

As demand for high-performance mining motors rises, Chinese manufacturers are responding by implementing rigorous quality control measures and investing in advanced manufacturing techniques. This strategic shift has allowed them to produce reliable and durable mining motors that meet international standards. Furthermore, by embracing sustainable practices and prioritizing environmental concerns, these companies are positioning themselves as leaders in an industry that is increasingly under pressure to operate responsibly. The result is a robust export market where Chinese mining motors are favored for their performance and value, solidifying the country's reputation in the global mining sector.

Innovative Technologies Driving the Mining Motor Industry Forward

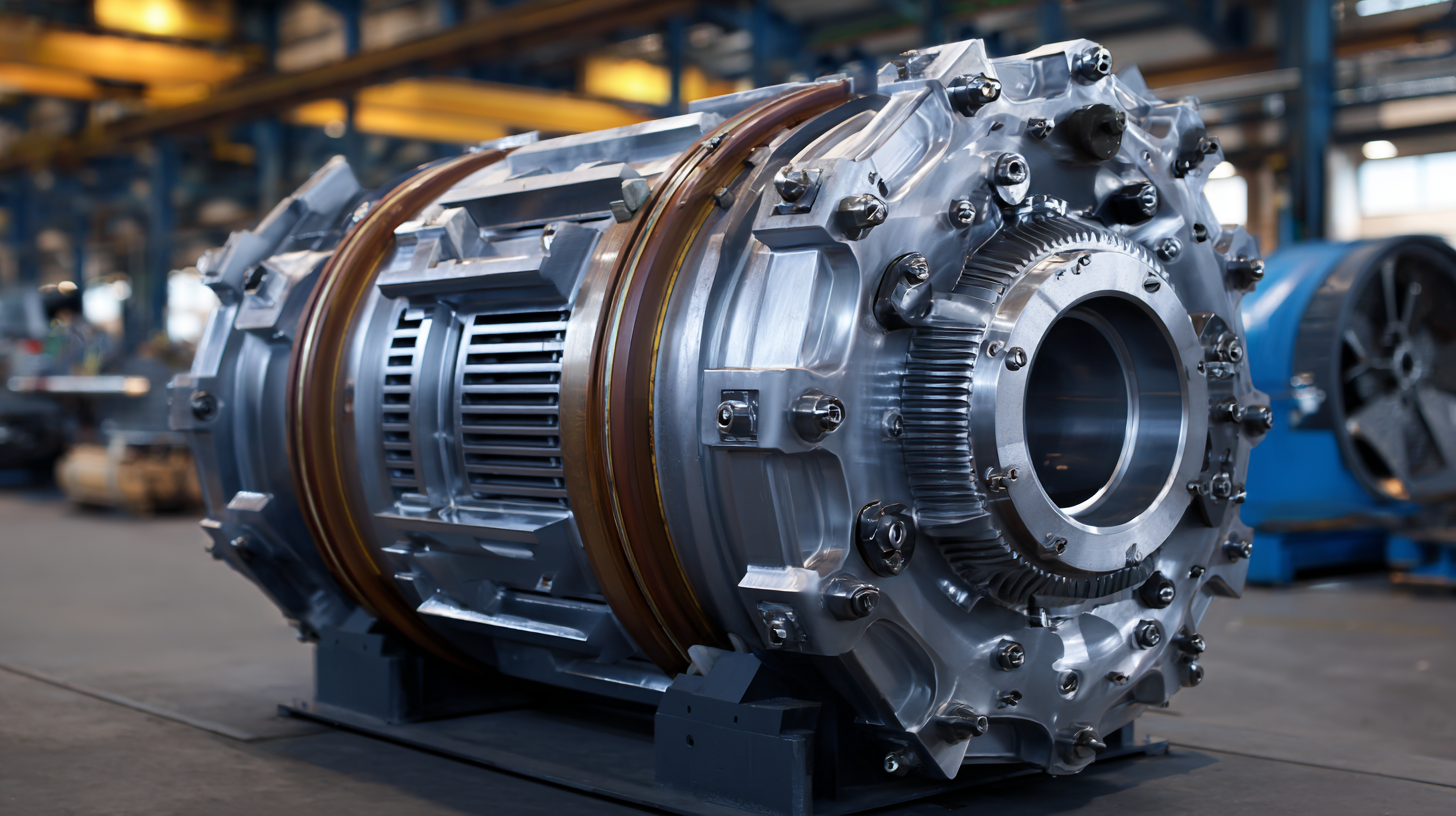

The mining motor industry is experiencing significant transformation driven by innovative technologies that aim to address ongoing challenges such as resource depletion and environmental sustainability. As reported in recent studies, approximately 30% of mining operations are now integrating advanced technologies including automation and electrification to enhance operational efficiency. The shift towards more sustainable practices is not merely an option; it's becoming a necessity as the industry seeks to reduce its environmental footprint.

One notable advancement is the emergence of lightweight and highly efficient motor systems designed for heavy mining equipment. These innovations are crucial as they support the electrification of operations, significantly reducing carbon emissions and operational costs. Additionally, mining safety technologies have evolved, leading to safer working conditions and improved operational efficiency. Recent advancements indicate that modern safety systems can reduce incident rates by up to 40%, highlighting the critical role technology plays in reshaping the mining landscape. With the projected growth of sustainable practices, the mining motor sector is poised to set new standards for performance and responsibility in the global market.

Quality Control Measures Ensuring Excellence in Production

In the competitive landscape of industrial manufacturing, quality control stands as a cornerstone that ensures excellence throughout the production process. In Chinese manufacturing, particularly in the mining motor sector, robust quality control measures are not merely guidelines; they are essential practices that set leading manufacturers apart. By implementing rigorous testing protocols and embracing advanced technologies, companies ensure that each motor meets international standards and withstands the harsh conditions commonly encountered in mining operations.

Utilizing a combination of automation and skilled craftsmanship, Chinese manufacturers have established a reputation for reliability and performance. Each production stage is meticulously monitored, from sourcing raw materials to the final assembly. Regular audits and inspections further reinforce this commitment, enabling manufacturers to identify and rectify potential issues before products reach the market. This unwavering dedication to quality not only boosts the trust of global clients but also positions Chinese mining motors as top contenders in the worldwide arena, showcasing how effective quality control can drive excellence and innovation in manufacturing.

Sustainable Practices in Chinese Manufacturing for Mining Solutions

In the quest for excellence in the global mining sector, Chinese manufacturing is carving a niche through sustainable practices. As the mining and metals industry undergoes profound transformation driven by energy transition and geopolitical shifts, the emphasis on green innovation has become paramount. This movement not only enhances operational efficiency but also sets higher environmental standards, aligning with global sustainability goals.

Recent discussions at climate summits underscore the importance of integrating financial strategies with sustainable practices. As leaders from governments, academia, and business converge to address climate change, the mining industry must prioritize eco-friendly solutions that resonate with stakeholders. This commitment to sustainability is pivotal as Chinese manufacturers seek to export not just products, but also robust standards that contribute to global environmental efforts. Thus, the future of mining solutions hinges on a seamless blend of advanced manufacturing techniques and an unwavering focus on sustainable practices.

Crafting Excellence with Chinese Manufacturing Bringing the Best Mining Motor to the Global Market - Sustainable Practices in Chinese Manufacturing for Mining Solutions

| Dimension | Value |

|---|---|

| Production Capacity (units/year) | 50,000 |

| Energy Efficiency (%) | 95 |

| Recycled Materials Used (%) | 30 |

| Lifecycle (years) | 10+ |

| Average Downtime (hours/year) | 50 |

| Carbon Footprint Reduction (%) | 20 |

| Global Market Presence (Countries) | 30 |

Global Partnerships: Expanding Reach and Impact in Mining Markets

Global partnerships are pivotal in expanding and enhancing the reach of the mining sector, especially as the demand for surface mining equipment skyrockets. The Global Surface Mining Equipment Market is projected to reach USD 103.10 billion by 2033, driven by a robust 7.10% CAGR. This growth reflects the urgent need for innovation and advanced technology in mining practices, as companies face unprecedented challenges in performance and efficiency.

To thrive in this evolving landscape, mining CEOs should focus on resilience through strategic partnerships. Collaborating with international manufacturers can provide access to cutting-edge machinery and best practices, thereby optimizing production and reducing operational costs. Additionally, diversifying supply chains mitigates risks associated with geopolitical factors and enhances market adaptability.

Tips for success in forging these global partnerships include conducting thorough market research to identify potential allies, establishing clear communication channels to foster collaboration, and aligning goals that focus on sustainability and innovation. By prioritizing these strategies, mining companies can enhance their competitive edge while contributing to a more sustainable and efficient industry.

Global Mining Motor Market Trends (2023)

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top