Rising Above Tariffs: How China's Best Induction Motors Thrive in a Competitive Market

In the wake of escalating tariffs between the United States and China, the induction motor industry has exhibited remarkable resilience, showcasing the prowess of Chinese manufacturers in a fiercely competitive landscape. According to a recent report by the International Electromechanical Commission, the global induction motor market is projected to reach $32 billion by 2025, driven by increasing demand for energy-efficient and sustainable technologies. Despite trade tensions, China's best induction motor producers have not only adapted to the shifting economic environment but have also capitalized on innovation and strategic investments. This upward trajectory highlights the ability of these manufacturers to thrive, leveraging advanced manufacturing techniques and superior product quality to maintain their competitive edge. As the industry continues to evolve, understanding the dynamics that enable these companies to rise above tariffs becomes essential for stakeholders and analysts alike.

The Impact of Tariffs on Global Trade Dynamics

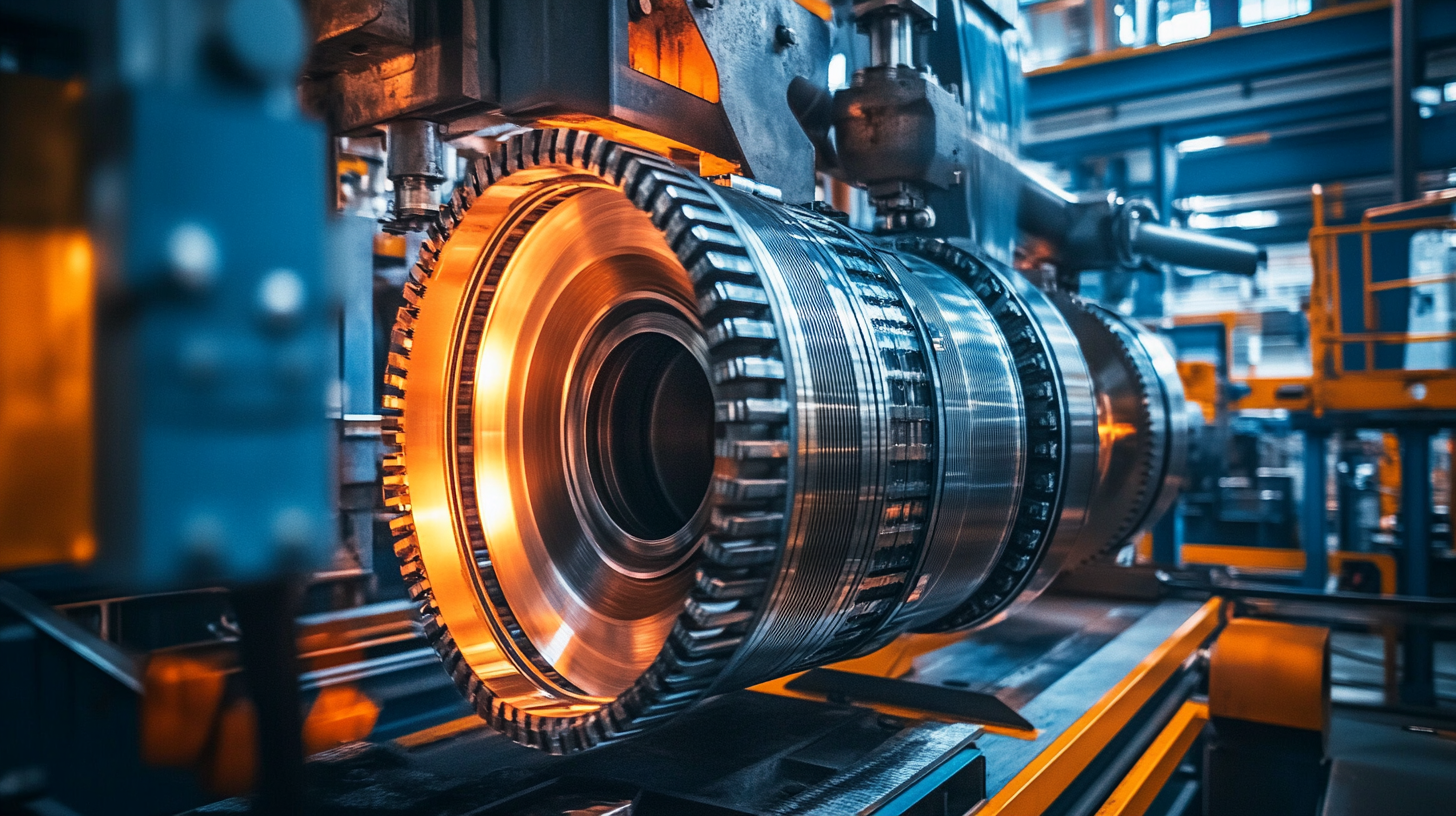

The impact of tariffs on global trade dynamics is profound, reshaping how countries engage in economic exchanges and adjust production strategies. In recent years, tariffs imposed on goods have led to a reevaluation of supply chains, compelling manufacturers to explore alternative markets and reevaluate their pricing strategies. For countries like China, where the manufacturing sector is robust, the challenge is to maintain competitiveness while navigating these tariff hurdles.

China’s best induction motors have found ways to excel despite these trade barriers. By focusing on innovation and improving production efficiency, these companies are not only mitigating the effects of tariffs but also positioning themselves as leaders in the global market. The investment in advanced technologies and adherence to international quality standards enables them to appeal to a broader audience. As a result, Chinese manufacturers demonstrate resilience in the face of adversity, emphasizing the importance of adaptability in an unpredictable trade environment.

Innovative Strategies of Chinese Induction Motor Manufacturers

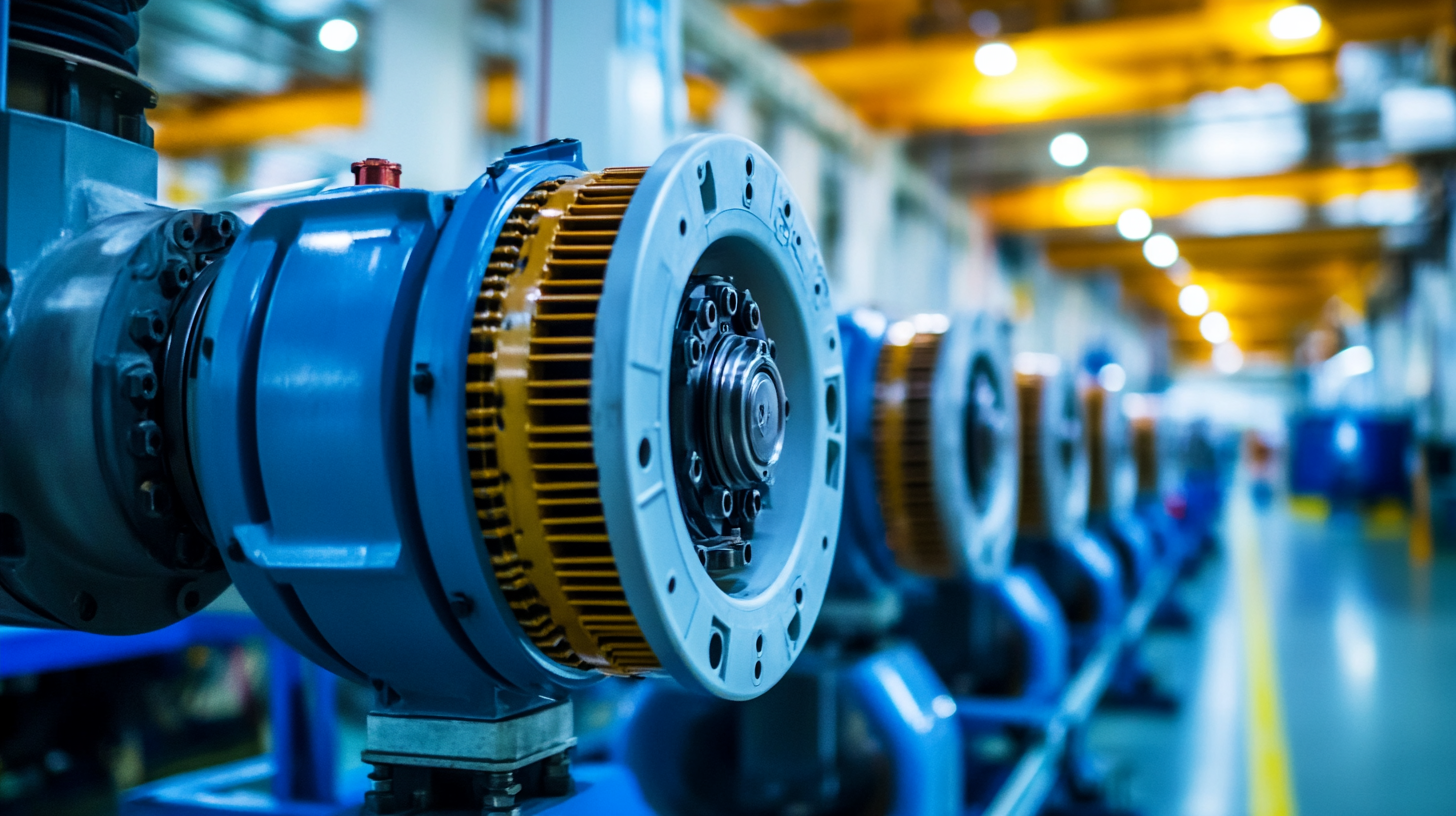

China's induction motor manufacturers are not just surviving amid rising tariffs; they are thriving by implementing innovative strategies that leverage technology and market insights. Recent reports indicate that the global electric motor market is expected to reach $152.4 billion by 2026, with a significant portion attributed to induction motors. In response to increased competition, Chinese producers are focusing on enhancing energy efficiency, with many adopting advanced designs that comply with international energy standards. For instance, the efficiency of premium-grade induction motors can reach up to 96%, significantly reducing operational costs over their lifecycle.

Furthermore, strategic partnerships and investments in research and development have enabled Chinese manufacturers to improve their product quality. As highlighted in the latest analysis by the International Energy Agency, market players that engage in continuous innovation are better positioned to adapt to shifting consumer demands and regulatory changes. Companies like Anhui Xinning and WEG are setting examples by integrating IoT technologies into their motor solutions, thereby providing real-time data analytics and predictive maintenance services. This trend not only enhances customer satisfaction but also strengthens market competitiveness in a region where agility and adaptability are crucial for success.

Rising Above Tariffs: How China's Best Induction Motors Thrive in a Competitive Market

| Manufacturer | Market Share (%) | Innovation Strategy | Export Markets | Sustainability Practices |

|---|---|---|---|---|

| Siemens Ltd. China | 30 | R&D investment in smart technology | Europe, North America | Energy-efficient designs, waste reduction |

| Wolong Electric | 25 | Vertical integration and automation | Asia, South America | Recycling motors, reducing carbon footprint |

| Jiangsu Tianyang Motor Co. | 15 | Focus on customization for industrial clients | Africa, Southeast Asia | Eco-friendly materials, energy conservation |

| Nanjing Starlight Electric | 10 | Advanced manufacturing techniques | Middle East, Eastern Europe | Low-emission production processes |

| Dongguan Yihong Motor Co. | 5 | Agile supply chain management | South Korea, Japan | Solar-powered operations |

The Role of Quality and Technology in Competitive Advantage

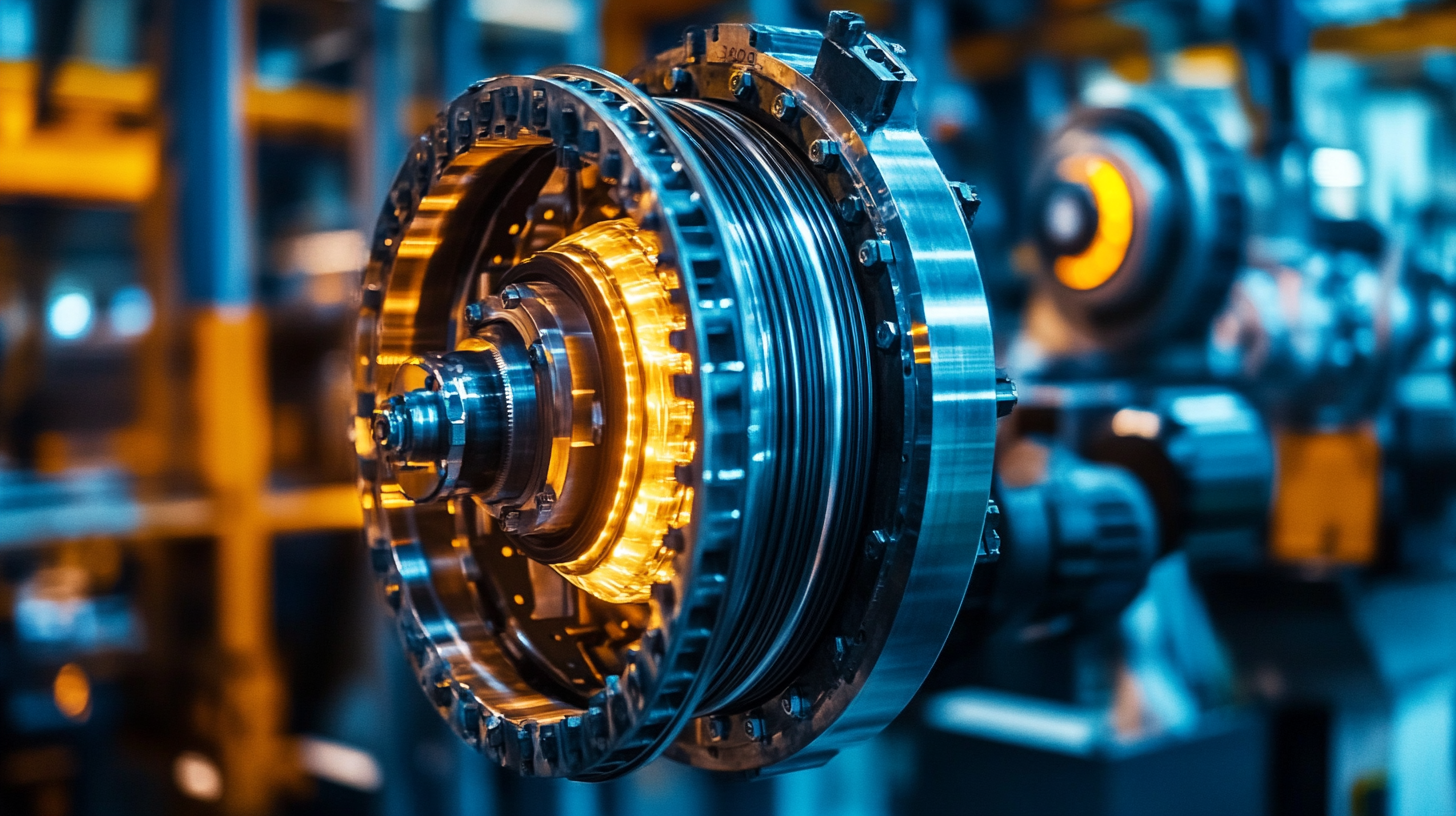

In a fiercely competitive market, the quality and technology behind China's best induction motors set them apart from their rivals. The relentless pursuit of excellence has driven manufacturers to invest significantly in advanced materials and innovative design processes. This emphasis on quality not only enhances performance and energy efficiency but also builds customer trust. As consumers become more discerning, the reputation for reliability and durability becomes a critical lever for success in attracting and retaining clients across various industries.

Moreover, the integration of cutting-edge technology plays a crucial role in ensuring these motors remain at the forefront of the market. Manufacturers are increasingly adopting smart technologies, including IoT capabilities, to provide real-time monitoring and predictive maintenance. This not only increases the operational lifespan of the products but also significantly lowers the total cost of ownership for customers. By harnessing the power of both superior craftsmanship and modern advancements, China's induction motor producers are not only rising above tariffs but are also forging a sustainable competitive advantage that positions them for future growth.

Rising Above Tariffs: How China's Best Induction Motors Thrive in a Competitive Market

Case Studies: Successful Chinese Brands in a Challenging Market

In the midst of fierce competition and escalating tariffs, several Chinese brands have emerged as leaders in the induction motor market through strategic innovation and adaptability. Companies like WEG and Nidec have not only enhanced their product offerings but also focused on value-added services that distinguish them in a crowded field. Their ability to pivot quickly and meet evolving customer needs has been crucial. Case studies showcasing these successful brands reveal a consistent emphasis on quality and efficiency, allowing them to not only survive but thrive even under challenging market conditions.

Tip: Focus on customer feedback to refine your products. Engaging with customers about their experiences with your induction motors can identify areas for improvement and innovation, which can set you apart from competitors.

Furthermore, these brands have invested heavily in advanced manufacturing technologies, optimizing production processes while maintaining high standards of environmental sustainability. By prioritizing technology, they have improved production efficiency and reduced operational costs, making them more competitive.

Tip: Embrace technology adaptation. Explore automation and AI solutions that streamline manufacturing processes, allowing you to respond rapidly to market demands without compromising on quality.

Future Trends for Induction Motors Amidst Trade Tensions

As trade tensions escalate, particularly between the U.S. and China, the induction motor market stands at a unique crossroads. Amid these challenges, industry reports indicate that China's induction motor manufacturers are adapting to changing market dynamics and regulatory environments. For instance, disruptions in the global semiconductor supply chain, stemming from geopolitical tensions, have prompted a reevaluation of sourcing strategies. The semiconductor market recorded its first growth since 2021, highlighting the resilience of certain sectors even amidst slow economic growth and ongoing chip shortages.

Moreover, the report on global supply chain disruptions emphasizes the necessity for businesses to build resilience in the face of adversity. This is especially pertinent for the induction motor industry, where international trade constraints require firms to innovate continually and find alternative supply paths. As manufacturers invest in advanced technologies and diversify their supply chains, they position themselves to thrive despite tariffs and other market challenges. The strategic pivot taken by these companies underscores a broader trend in the energy sector toward sustainable and efficient solutions, aligning with global ambitions for carbon neutrality.

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top