Understanding the Power: How Centrifugal Pump Motors Enhance Industrial Efficiency

In the rapidly evolving landscape of industrial operations, enhancing efficiency is a primary concern for manufacturers. One pivotal component in achieving this goal is the Centrifugal Pump Motor, which plays a crucial role in fluid management across various industries. According to the U.S. Department of Energy, motors, including centrifugal pump motors, consume approximately 69% of the electrical energy used in industrial facilities, emphasizing the need for optimal performance and energy efficiency. Furthermore, the potential for energy savings from upgraded or properly maintained centrifugal pump systems can exceed 20%, as highlighted by the American Council for an Energy-Efficient Economy. By understanding the intricacies of centrifugal pump motors and implementing best practices, industries can significantly reduce operational costs while improving productivity and sustainability. This article delves into the functionality and impact of centrifugal pump motors, offering insights into how they empower industries to drive efficiency forward.

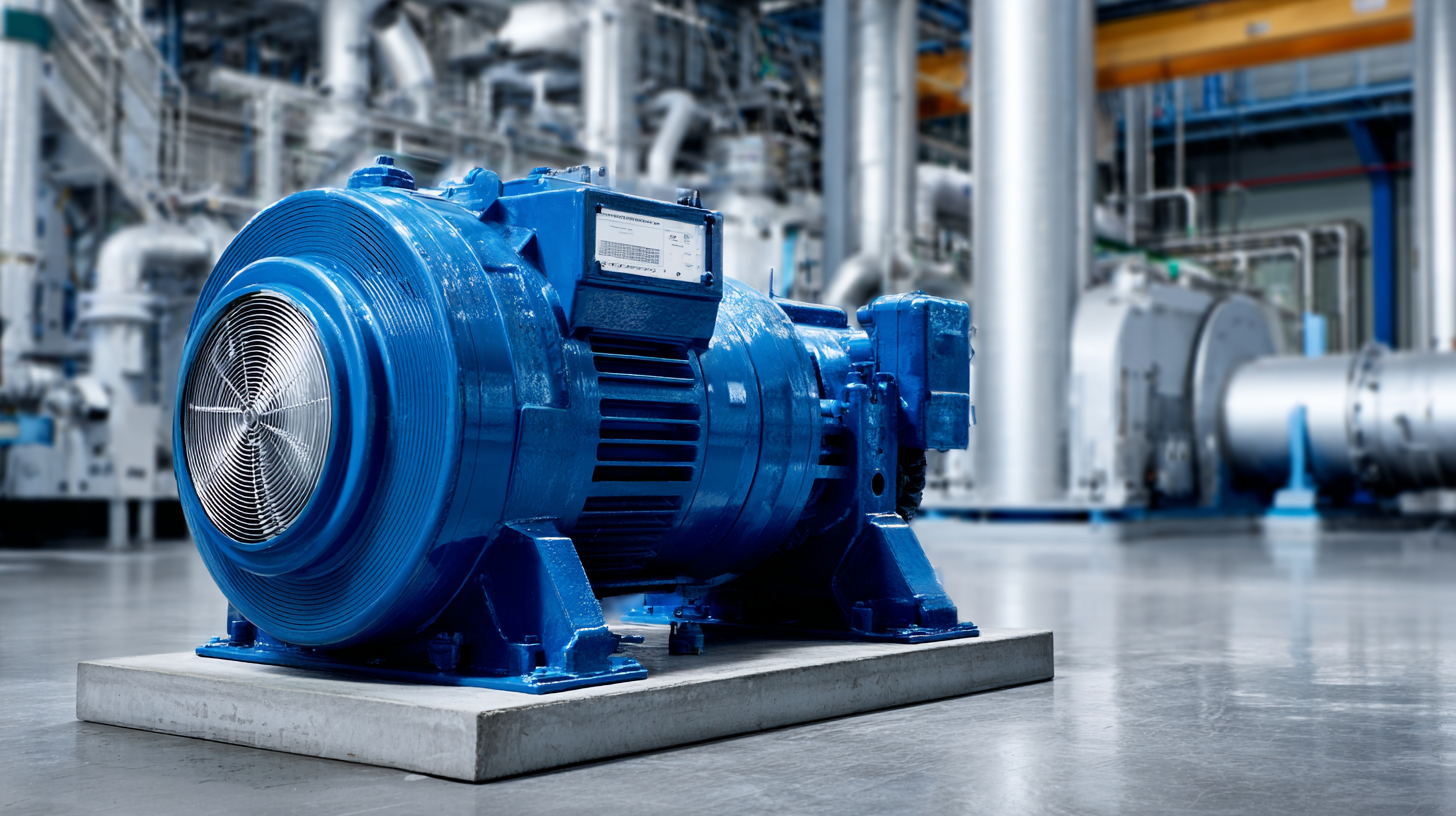

The Role of Centrifugal Pump Motors in Modern Industry

Centrifugal pump motors play a critical role in modern industry, driving efficiency across various sectors including manufacturing, water treatment, and oil and gas. According to a report by the U.S. Department of Energy, centrifugal pumps account for approximately 25% of the total electrical energy consumed in industrial applications. The design of these motors allows for the conversion of electrical energy into mechanical energy, providing optimal fluid movement with minimal energy loss. This efficiency is essential as industries strive to reduce operational costs while maximizing productivity.

Moreover, advancements in technology have significantly enhanced the performance of centrifugal pump motors. The latest models incorporate features like variable frequency drives (VFDs), which can optimize pump speed and improve operational flexibility. A study by the Hydraulic Institute indicates that implementing VFDs on centrifugal pumps can lead to energy savings of 15-50%, showcasing the tangible benefits of modern pump motors. As industries continue to embrace sustainable practices, the importance of efficient centrifugal pump motors will only increase, proving to be a cornerstone of industrial progress and environmental responsibility.

Advantages of High-Efficiency Motors in Pump Systems

High-efficiency motors are integral to optimizing the performance of centrifugal pump systems in industrial settings. According to a report from the U.S. Department of Energy, transitioning to high-efficiency motors can result in energy savings of 2-8% compared to standard motors. This reduction not only diminishes operational costs but also significantly lowers the carbon footprint of industrial operations. High-efficiency motors are designed with advanced materials and technologies, allowing them to operate at higher performance levels, which is crucial for maintaining productivity in demanding environments.

In addition to energy savings, high-efficiency motors offer enhanced reliability and longevity, often extending service life by more than 15%. A study by the Electric Power Research Institute (EPRI) indicates that the initial investment in high-efficiency motors can be recouped within two years through energy savings alone. This is particularly important for industries that rely heavily on centrifugal pumps, such as water treatment and chemical processing, where downtime can lead to substantial financial loss. By integrating these high-performance motors, businesses can not only improve their operational efficiency but also contribute to a more sustainable industrial future.

Understanding the Power: How Centrifugal Pump Motors Enhance Industrial Efficiency - Advantages of High-Efficiency Motors in Pump Systems

| Efficiency Category | Motor Power (kW) | Pump Flow Rate (m3/h) | Total Efficiency (%) | Energy Savings (kWh/year) |

|---|---|---|---|---|

| Standard Motor | 75 | 150 | 85 | 12,000 |

| High-Efficiency Motor | 75 | 150 | 92 | 20,400 |

| Premium Efficiency Motor | 75 | 150 | 95 | 24,000 |

| IE3 Rated Motor | 75 | 150 | 90 | 18,000 |

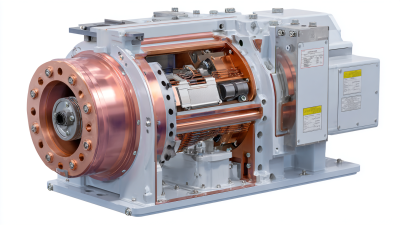

Impact of Motor Design on Pump Performance and Reliability

Centrifugal pumps are crucial in various industrial applications, and the performance of these pumps is significantly influenced by the design of their motors. Motor design encompasses various factors, including efficiency, torque characteristics, and cooling mechanisms, all of which impact how effectively a pump can move fluids. A well-designed motor can enhance a pump’s efficiency, ensuring that it operates smoothly and optimally under varying load conditions. By prioritizing energy-efficient designs, industries can not only reduce operational costs but also minimize their environmental footprint.

Moreover, the reliability of centrifugal pumps is closely tied to motor design. Motors that feature robust construction and advanced materials can withstand the rigors of continuous operation, preventing premature failures that result in costly downtime. Additional design elements, such as vibration dampening and thermal management systems, play a key role in extending the lifespan of the motor and the pump it drives. When both motor and pump are efficiently designed, they work in harmony, leading to improved overall system performance and long-term reliability in industrial processes.

Understanding the Power: Centrifugal Pump Motors and Their Impact on Efficiency

The above chart illustrates the efficiency percentages of different centrifugal pump motor designs. It highlights how variations in motor design can directly influence the overall operational efficiency of industrial applications.

Energy Savings and Cost Reduction through Enhanced Pump Operations

Centrifugal pump motors play a crucial role in optimizing industrial operations, particularly through their ability to enhance energy efficiency. By utilizing advanced technologies, these motors are designed to operate at optimal performance levels, reducing energy consumption significantly. This efficiency not only lowers operational costs but also contributes to sustainability efforts in various industries, allowing companies to meet environmental standards while saving on energy bills.

Moreover, enhanced pump operations lead to improved system performance, resulting in longer equipment lifespans and reduced maintenance requirements. When pumps operate efficiently, there is less wear and tear on components, minimizing the need for repairs and replacements. Consequently, businesses can allocate financial resources more effectively, redirecting savings towards innovation and growth rather than on maintaining outdated systems. The synergy between centrifugal pump motors and energy management is crucial for achieving substantial cost reductions in today's competitive industrial landscape.

Future Trends in Centrifugal Pump Motor Technology and Efficiency

Recent advancements in centrifugal pump motor technology have paved the way for significant improvements in industrial efficiency. According to a report by the U.S. Department of Energy, it is estimated that optimizing pump systems can lead to energy savings of up to 20-50%. This highlights the critical role that advanced motor designs and control systems play in enhancing the performance of centrifugal pumps. The integration of variable frequency drives (VFDs) allows for precise control over pump speed, which not only improves efficiency but also reduces wear and tear, prolonging the lifespan of equipment.

Looking ahead, the industry is witnessing a shift towards more sustainable and smart pump motor solutions. Reports from MarketsandMarkets project that the global market for smart pumps will reach $14.66 billion by 2025, fueled by the growing demand for energy-efficient technologies. These pumps will increasingly incorporate IoT (Internet of Things) capabilities, enabling real-time monitoring and predictive maintenance. As manufacturers focus on developing lightweight materials and energy-efficient designs, the efficiency of centrifugal pump motors is expected to significantly enhance, leading to both cost savings and reduced environmental impact in industrial applications.

Related Posts

-

Maximize Your Global Sourcing: Discover Cutting-Edge Centrifugal Pump Motors at the 2025 Canton Fair

-

Unmatched Quality of Best Cast Iron Motors from World Leading Chinese Manufacturers

-

7 Excellent Benefits of Using Low Speed Motors for Your Business

-

How to Choose the Right Electric Motor for Your Specific Needs

-

Understanding the Magic Behind Electrical Fan Motors: How They Keep You Cool

-

Choosing the Right Manufacturer for the Best Asynchronous Motor to Maximize Your Investment

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top