Top 10 Centrifugal Pump Motor Benefits You Should Know?

Centrifugal Pump Motors play a critical role in various industries. These motors are known for efficiency and reliability. They help in moving fluids effectively, making them essential in many applications.

The benefits of using a Centrifugal Pump Motor are significant. They offer energy savings and require less maintenance. This can lead to lower operational costs over time. However, it is essential to choose the right motor for specific needs. Not all motors will perform optimally under every circumstance.

Understanding the advantages can improve decision-making. It’s important to reflect on how these motors impact overall productivity. While there are many benefits, potential drawbacks exist too. Choosing a suitable Centrifugal Pump Motor can sometimes be complex. That said, recognizing these factors can lead to better outcomes in the long run.

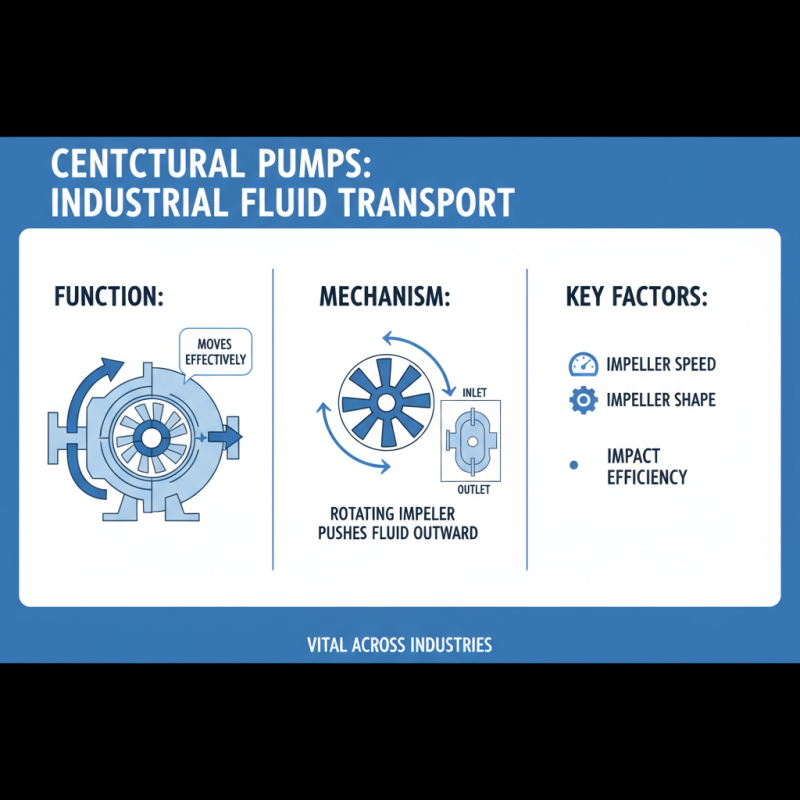

Understanding Centrifugal Pumps and Their Motors

Centrifugal pumps are vital in various industries. They are designed to move fluids effectively. Understanding how they work is key. A centrifugal pump uses a rotating impeller. This impeller pushes fluid outwards. The speed and shape of the impeller impact efficiency.

Tips: Check the pump's flow rate. It should match your needs. Oversized pumps waste energy. Conversely, undersized pumps can fail. Maintenance is crucial. Regular checks help prevent issues.

The motor used in these pumps also matters. It determines the pump's performance. A reliable motor offers consistent power. Different motors handle various applications. Some can run in harsh environments. Consider the motor's energy consumption. It affects operating costs.

Tips: Always review motor specifications. Match them closely with pump requirements. Incompatible motors can lead to inefficiency. Sometimes, a small change in motor can boost performance. Evaluate your system regularly for potential upgrades.

Key Benefits of Using Centrifugal Pump Motors

Centrifugal pump motors offer significant advantages in various applications. Their efficiency in transferring fluids makes them a popular choice in industries. According to a recent study, centrifugal pumps can achieve up to 90% efficiency, reducing operational costs. This performance is essential in applications like water treatment and industrial processes.

One of the key benefits is reliability. These motors tend to have fewer moving parts, which limits wear and tear. This longevity can lead to reduced maintenance costs. However, it's crucial to monitor their operational parameters regularly. Overheating can occur if they operate outside their designed capacity. This could lead to unexpected downtimes.

Tip: Always ensure proper cooling and ventilation for your motor.

Another advantage is the versatility of centrifugal pump motors. They can handle a wide range of fluids, including chemicals and slurries. A research report highlighted that these pumps maintain optimal performance even in challenging conditions. Yet, they can be susceptible to cavitation, which can cause serious damage.

Tip: Regularly inspect your centrifugal pump for signs of cavitation.

In many cases, the adaptability of these motors supports innovations in system designs. It's important to recognize that while they have many benefits, continuous assessment of performance is vital.

Energy Efficiency and Cost Savings of Centrifugal Pump Motors

Centrifugal pump motors play a crucial role in energy efficiency. These motors can save companies significant costs over time. According to a report from the U.S. Department of Energy, optimizing pump systems can reduce energy consumption by up to 20%. This is not just theory; many industries see real savings through efficiency upgrades.

Various studies suggest that improving motor efficiency can lead to annual savings of $20,000 to $30,000. This depends on the application and usage of the pumps. Some companies still use older models. These aging systems can drive up both energy costs and maintenance needs. Innovations in motor technology are key to overcoming these challenges.

Beyond energy savings, the longevity of centrifugal pump motors warrants attention. Their design often allows for easy maintenance and fewer breakdowns. Regular maintenance can extend their lifespan. However, many operators overlook this aspect, leading to higher lifecycle costs. Awareness of these benefits is critical for both operational efficiency and financial savings.

Low Maintenance Requirements of Centrifugal Pump Motors

Centrifugal pump motors are popular for their low maintenance requirements. This feature makes them appealing in various industries. Regular servicing is minimal, allowing for extended operational periods. Many users appreciate the straightforward design, which simplifies maintenance tasks.

These motors often come with fewer components than other types. This contributes to their reliability. Some users might overlook potential issues, however. For instance, the pump might need occasional bearing checks. Ignoring small maintenance tasks can lead to larger problems down the line.

Even with low maintenance, attention is still necessary. Observing unusual sounds or vibrations can be crucial. Users should remain proactive about monitoring the performance. Proper care ensures that the benefits of these motors are fully realized. Skipping routine checks may result in unexpected downtime and repairs.

Top 10 Centrifugal Pump Motor Benefits You Should Know

| Benefit | Description |

|---|---|

| Low Maintenance | Centrifugal pump motors are designed to require less frequent maintenance, reducing downtime and operational costs. |

| Energy Efficient | These motors operate efficiently, consuming less energy and providing cost savings on electricity bills. |

| Reliable Performance | Centrifugal pump motors offer stable performance, ensuring consistent operation in various applications. |

| Simple Design | The straightforward design of centrifugal pumps allows for easier installation and maintenance. |

| Variety of Applications | They can be used in multiple industries ranging from water supply to chemical processing. |

| High Flow Rates | Centrifugal pump motors are capable of handling high flow rates, making them ideal for large-scale operations. |

| Low Cost | They often have lower upfront costs compared to other pump types, offering an economic solution for many applications. |

| Portability | Centrifugal pumps can be designed to be lightweight and portable, suitable for varying locations. |

| Durability | Constructed from robust materials, they are built to last in tough environments. |

| Quiet Operation | Centrifugal motors typically operate with reduced noise, contributing to a quieter working environment. |

Versatility and Application Range of Centrifugal Pump Motors

Centrifugal pump motors offer remarkable versatility across various industries. Their design allows for efficient fluid movement in applications such as water treatment, chemical processes, and HVAC systems. According to industry reports, over 70% of industrial fluid handling uses centrifugal pumps due to their efficiency and adaptability. This broad application range makes them indispensable.

In water treatment, for instance, centrifugal pumps can handle both clean and dirty water, showcasing their flexibility. They operate effectively in various environments, from residential buildings to large-scale industrial facilities. However, not all models are designed for every situation. It’s crucial to choose the right type for specific needs.

Tips: Always assess the operating conditions. Incorrect selection can lead to inefficiency. Ensure your pump motor has the appropriate power rating for your application. Many operators overlook power calculations. This oversight can cause performance issues. Regular maintenance, although sometimes neglected, is key to longevity. Don’t skip it. The importance of proper installation can't be stressed enough. Inaccurate setup might result in operational failures.

Related Posts

-

Maximize Your Global Sourcing: Discover Cutting-Edge Centrifugal Pump Motors at the 2025 Canton Fair

-

Why Choose a Pump Motor for Your Industrial Applications?

-

How to Choose the Right Mining Motor for Your Operations

-

Exploring Innovative Rv Gearbox Options: Data-Driven Insights for Global Buyers

-

How to Choose the Best Three Phase Ac Motor for Your Industrial Needs

-

7 Compelling Advantages of Choosing the Right Fire Pump for Your Needs

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top