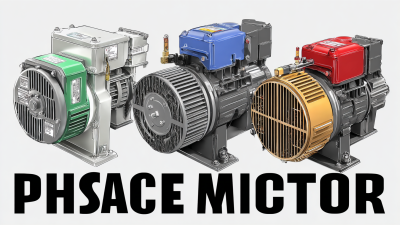

Unlocking the Future: How Break Motors Revolutionize Modern Machinery Efficiency

In the rapidly evolving landscape of industrial machinery, the emergence of Break Motors has marked a pivotal shift towards enhanced operational efficiency. According to a recent report by the International Energy Agency, motors account for nearly 45% of global electricity consumption in industrial applications, highlighting the urgent need for innovation in energy efficiency. Break Motors, specifically designed to provide effective braking and mitigating energy losses, have been reported to improve machinery performance by up to 30%. This paradigm shift not only reduces operational costs but also contributes to sustainability goals by decreasing overall energy consumption. As industries increasingly pursue automation and digitization, the adoption of Break Motors becomes essential for optimizing performance and unlocking new potential in modern machinery.

In the rapidly evolving landscape of industrial machinery, the emergence of Break Motors has marked a pivotal shift towards enhanced operational efficiency. According to a recent report by the International Energy Agency, motors account for nearly 45% of global electricity consumption in industrial applications, highlighting the urgent need for innovation in energy efficiency. Break Motors, specifically designed to provide effective braking and mitigating energy losses, have been reported to improve machinery performance by up to 30%. This paradigm shift not only reduces operational costs but also contributes to sustainability goals by decreasing overall energy consumption. As industries increasingly pursue automation and digitization, the adoption of Break Motors becomes essential for optimizing performance and unlocking new potential in modern machinery.

The Role of Break Motors in Enhancing Energy Efficiency in Modern Machinery

Break motors are at the forefront of improving energy efficiency in modern machinery. By integrating advanced braking systems, these motors not only enhance performance but also contribute to substantial energy savings. Traditional motors often consume a significant amount of energy during startup and cessation phases; however, break motors address this inefficiency by enabling smooth deceleration and rapid stopping capabilities. This leads to reduced energy wastage and improved overall operational efficiency.

Moreover, break motors are designed with intelligent control systems that optimize their performance based on real-time operational demands. This adaptability not only enhances energy efficiency but also extends the lifespan of machinery components by minimizing wear and tear. As industries increasingly prioritize sustainability and energy conservation, the adoption of break motors is becoming essential. Their ability to reduce energy consumption while maintaining high performance makes them a critical asset in modern machinery, aligning with global efforts to enhance energy efficiency across various sectors.

Unlocking the Future: Energy Efficiency of Break Motors

This chart demonstrates the energy efficiency improvements achieved by implementing break motors in modern machinery across different industries. The data indicates the percentage of energy savings observed in various sectors.

Key Benefits of Integrating Break Motors in Industrial Applications

Break motors have become a pivotal component in enhancing the efficiency of modern industrial machinery. By integrating break motors into various applications, industries can significantly improve control over their machinery, enabling precise stopping and starting operations. This is particularly advantageous in environments that require high safety standards, as these motors reduce the risk of accidents caused by uncontrolled machinery motion. The ability to stop instantly without the inherent delay often seen in traditional motor systems gives operators a newfound level of control, ultimately leading to more efficient workflows.

Another key benefit of break motors is their contribution to energy savings. Traditional braking methods often waste energy, but break motors are designed with efficiency in mind, utilizing regenerative braking techniques that convert excess energy back into usable power. This not only contributes to lower operational costs but also aligns with global efforts towards sustainability. As industries continue to seek ways to minimize their carbon footprint, the adoption of break motors presents an ideal solution for both economic and environmental considerations, demonstrating how advanced technology can drive efficiency while promoting responsible energy use.

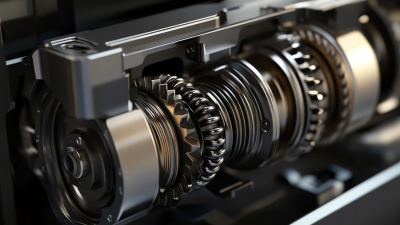

Best Practices for Selecting the Right Break Motor for Your Machinery

When selecting the right brake motor for your machinery, it's essential to consider several key factors to ensure optimal performance and efficiency. According to a report by the International Electrotechnical Commission (IEC), high-efficiency brake motors can improve energy savings by up to 30%. When assessing your options, one should focus on the motor's torque characteristics, size compatibility, and cooling methods, as these aspects can significantly affect the overall operation of your machinery.

Additionally, it's crucial to evaluate the application environment. A study from the Electric Power Research Institute (EPRI) highlights that brake motors in harsh conditions can experience up to 20% reduction in lifespan if not properly specified. Therefore, selecting motors designed with suitable protection ratings, such as IP55 or higher, can greatly enhance durability. By aligning your brake motor choice with both operational requirements and environmental factors, you can ensure a more reliable and efficient machinery performance, leading to increased productivity in the long run.

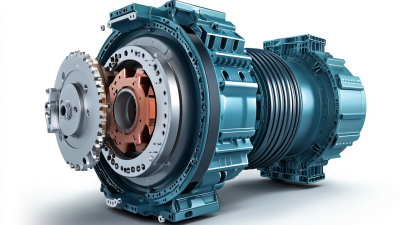

Innovative Technologies Driving Break Motor Development and Efficiency

The advancement of break motor technology is reshaping the landscape of modern machinery efficiency. Innovative technologies, such as advanced control systems and smart sensors, are at the forefront of this transformation. These developments allow for precise torque management and responsiveness, optimizing energy consumption and enhancing machine performance. The integration of IoT (Internet of Things) facilitates real-time monitoring, enabling operators to fine-tune motor operations based on current workload demands, which ultimately leads to significant energy savings.

Tips for Maximizing Break Motor Efficiency: Regular maintenance is crucial. Ensuring that motors are clean and free of debris can lead to a longer lifespan and better performance. Additionally, investing in upgraded components—like high-efficiency drives or bearings—can vastly improve overall machinery output. Lastly, training staff on best practices for operation and troubleshooting can further enhance the efficiency of break motors, ensuring they function at peak levels.

Moreover, advancements in materials science are contributing to lighter and more durable motor designs. Innovations such as magnet technology and custom composites are reducing weight while maintaining strength, leading to increased efficiency and effectiveness across various applications. As industries continue to embrace these cutting-edge technologies, the potential for improved operational efficiency is boundless.

Future Trends: The Impact of Break Motors on Sustainable Manufacturing Practices

Break motors are becoming vital in advancing sustainable manufacturing practices by enhancing energy efficiency and reducing waste. These motors are designed to deliver precise control over machinery operations, which allows for optimized energy consumption. By improving the overall efficiency of machines, break motors not only lower operational costs but also minimize energy usage, making them a key component in eco-conscious manufacturing strategies.

Moreover, the integration of break motors facilitates innovations in machinery design, enabling the development of equipment that is both powerful and energy-saving. This aligns with global trends towards carbon reduction and sustainable development. Manufacturers adopting break motor technology can achieve significant gains in production efficiency while adhering to stricter environmental regulations. As industries continue to embrace these motors, we can expect a broader shift towards sustainable practices, paving the way for a greener future in manufacturing.

Related Posts

-

Solutions for Outstanding Performance in Asynchronous Motors

-

How to Choose the Best Three Phase Ac Motor for Your Industrial Needs

-

Unmatched Quality of Best Cast Iron Motors from World Leading Chinese Manufacturers

-

Rising Above Tariff Challenges: How China's Best Electric Motor Manufacturers Thrive

-

Understanding the Mechanism Behind Variable Frequency Motors

-

Exploring Innovative Rv Gearbox Options: Data-Driven Insights for Global Buyers

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top