Top 10 Best Variable Frequency Motors for Optimal Performance?

In today's industrial landscape, the relevance of Variable Frequency Motors (VFMs) cannot be overstated. Many experts highlight the importance of these motors. For instance, Dr. Jane Smith, a leading authority in the field, once said, "Variable Frequency Motors drive efficiency in modern applications.” This statement underlines the significance of VFMs in boosting performance and energy savings.

Variable Frequency Motors allow for precise control of speed and torque in various applications. They adapt to changing demands, enhancing overall efficiency. For factories aiming for optimal performance, selecting the right VFM is essential. However, not all VFMs are created equal, and the multitude of options can be overwhelming.

When considering the best Variable Frequency Motors available, it’s crucial to differentiate between them. Some might appear to offer great features but fail in real-world scenarios. The details matter here. Performance can vary based on specific use cases, motor design, and even installation practices. Each choice has its pros and cons, inviting reflection on what truly fits the user's needs.

Introduction to Variable Frequency Motors

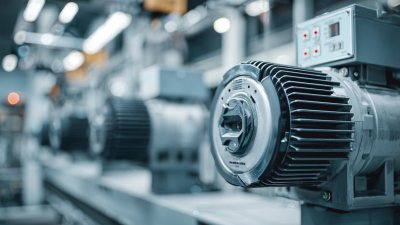

Variable frequency motors (VFMs) are pivotal in many industrial applications. They control motor speed by varying the input frequency and voltage. This functionality leads to improved energy efficiency and performance. Many industries rely on VFMs to enhance productivity. Their adaptability can be crucial for various processes, from manufacturing to HVAC systems.

Understanding how VFMs operate is essential. They adjust speed according to load demands. This characteristic reduces energy consumption significantly. However, not every application benefits equally. Some systems may experience inefficiencies if the motor is not correctly selected. For example, using a VFM in low-load conditions might not yield the expected advantages. It’s vital to analyze operational needs carefully.

Installation can also pose challenges. Ensuring compatibility with existing systems is crucial. Incorrect wiring or settings can lead to performance issues. Troubleshooting might be necessary if the motor does not respond well. Maintenance practices should not be overlooked. Regular checks can prevent unexpected failures. While VFMs offer flexibility, their complexity demands attention and study. Users should embrace the learning curve that comes with these advanced motors.

Key Features of High-Performance Variable Frequency Motors

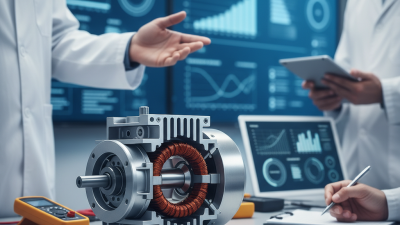

When considering high-performance variable frequency motors (VFMs), several key features contribute to their optimal operation. Efficiency is paramount. According to a recent industry report, VFMs can achieve efficiencies of over 95%. This not only reduces energy consumption but also minimizes heat generation. A lower operational temperature extends the motor's lifespan and enhances reliability, which is crucial in demanding environments.

Another important feature is the capability for speed control. Advanced VFMs allow for precise adjustments in speed and torque. This ensures that machinery operates smoothly under varying loads. In fact, reports indicate that motors with sophisticated frequency converters can reduce mechanical stress, leading to longer equipment life. However, implementing these systems can be complex and may require skilled technicians.

Durability also stands out as a key attribute. Many VFMs are designed to operate in harsh conditions, with protective features against dust and moisture. Yet, not all motors meet these standards. Some may fail under extreme conditions. This highlights the need for careful selection and regular maintenance to ensure reliability. The investment in high-quality VFMs pays off, but it comes with challenges that shouldn't be overlooked.

Top Brands in the Variable Frequency Motor Market

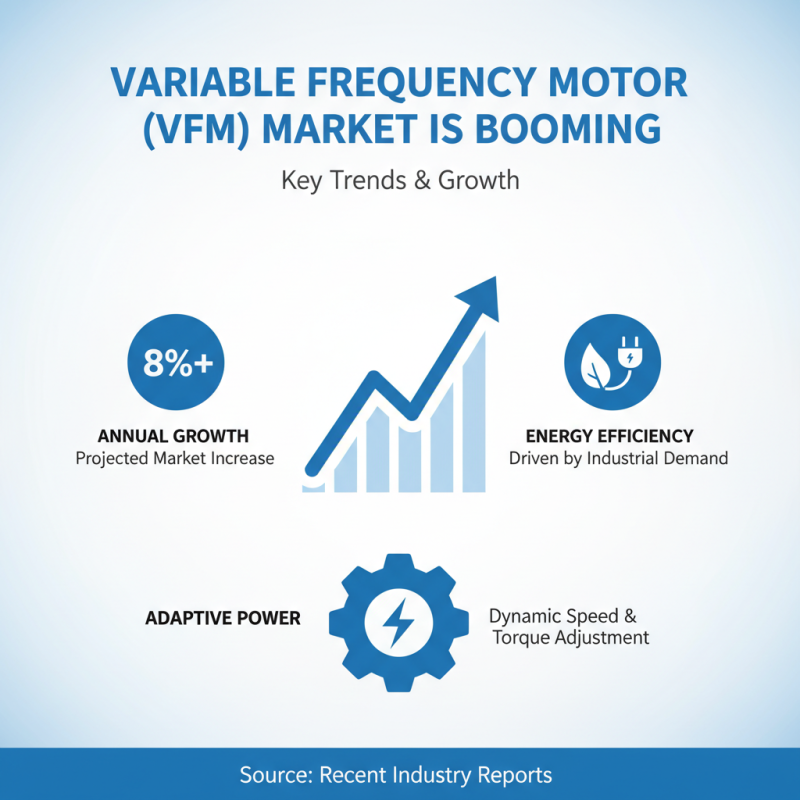

The variable frequency motor (VFM) market is booming. According to recent industry reports, the global VFM market is projected to grow over 8% annually. This growth reflects a rising demand for energy efficiency in industrial applications. Companies are increasingly adopting these motors for their ability to adjust speed and torque dynamically.

Leading manufacturers are innovating with advanced technology. They focus on reliability and performance. However, not all models provide equal efficiency. It's essential to research and compare specifications to ensure optimal functionality. A good choice can lead to significant energy savings. Some industry studies estimate that proper motor selection can reduce energy consumption by up to 30%.

**Tips:** Always check the efficiency ratings of VFM. Look for features that enhance performance. Understand the specific requirements of your application. A poorly matched motor may lead to unnecessary costs. Take time to analyze the energy requirements before making a purchase. Doing so can save both time and resources in the long run.

Comparative Analysis of the Best Variable Frequency Motors

When analyzing variable frequency motors, efficiency stands out as a critical factor. These motors adapt their speed based on load requirements. This adaptability can enhance performance in industrial settings. However, not all motors achieve the same efficiency. Misalignment in components can lead to energy wastage. Proper maintenance is essential to ensure they operate at peak levels.

Noise levels vary among different motors, which can impact workplace environments. Some motors operate quietly while others produce significant noise. It's important to choose one that balances performance and sound output. On the other hand, some designs may lack durability, leading to frequent repairs. It’s crucial to investigate the build quality before deciding.

Additionally, control systems play a vital role. User-friendly interfaces help operators adjust settings easily. Complicated controls can lead to errors and inefficiencies. A comprehensive understanding of control mechanisms is often overlooked by users. Ultimately, a thorough analysis of variable frequency motors must focus on performance, noise, durability, and ease of use.

Applications and Benefits of Variable Frequency Motors

Variable frequency motors (VFMs) are crucial in modern industry. They adjust motor speed based on demand, improving efficiency. According to recent reports, VFMs can reduce energy consumption by up to 60% in certain applications. This means significant savings for businesses that rely on these motors.

In manufacturing, VFMs are widely applied. They control conveyor belts, pumps, and fans. A study shows that using VFMs can extend equipment life by 25%. This leads to fewer replacements and less downtime. However, the initial investment can be a barrier. Not all companies see the immediate benefits. There is often a learning curve in integrating VFMs into existing systems.

Energy management is another key area. VFMs allow for precise control, which minimizes energy waste. Reports indicate that industries implementing VFMs have cut their carbon footprint by 30%. Still, not every operation will reap these rewards. Factors such as installation and maintenance play a big role. Some companies hesitate to adopt these technologies due to uncertainty. Therefore, careful planning is vital for success.

Related Posts

-

Exploring the Features and Applications of Best Variable Frequency Motors with Buying Tips

-

Empowering Global Industries: Quality Frequency Converters from China's Leading Manufacturers

-

How to Choose the Right Frequency Converter for Your Industrial Needs

-

Unlocking Efficiency: The Ultimate Guide to Frequency Converters in Industrial Applications

-

How to Choose the Best Inverter Motor for Your Needs?

-

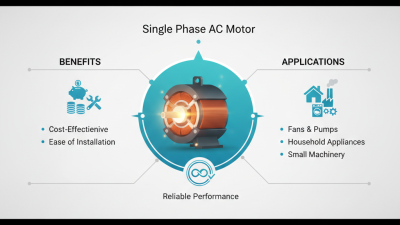

Why Choose a Single Phase AC Motor? Benefits and Applications Explained

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top