5 Reasons Why the Best Three Phase AC Motor is Essential for Your Industry Needs

In the rapidly evolving landscape of industrial applications, the importance of the Three Phase AC Motor cannot be overstated. As reported by the International Energy Agency, the demand for electric motors is expected to grow significantly, with projections indicating a market increase of around 5% annually over the next decade. The Three Phase AC Motor stands out as a pivotal solution in meeting energy efficiency and performance standards across various sectors. Its ability to deliver high starting torque and smooth operation makes it indispensable for heavy machinery, manufacturing processes, and various automation systems. Furthermore, a report by MarketsandMarkets highlights that the increasing adoption of automation in industries will further bolster the necessity for advanced motor technologies, including the Three Phase AC Motor, to ensure higher productivity and reduced operational costs. Understanding the key benefits of this powerhouse is essential for industries aiming to thrive in 2025 and beyond.

Understanding the Importance of Three Phase AC Motors in Industrial Applications

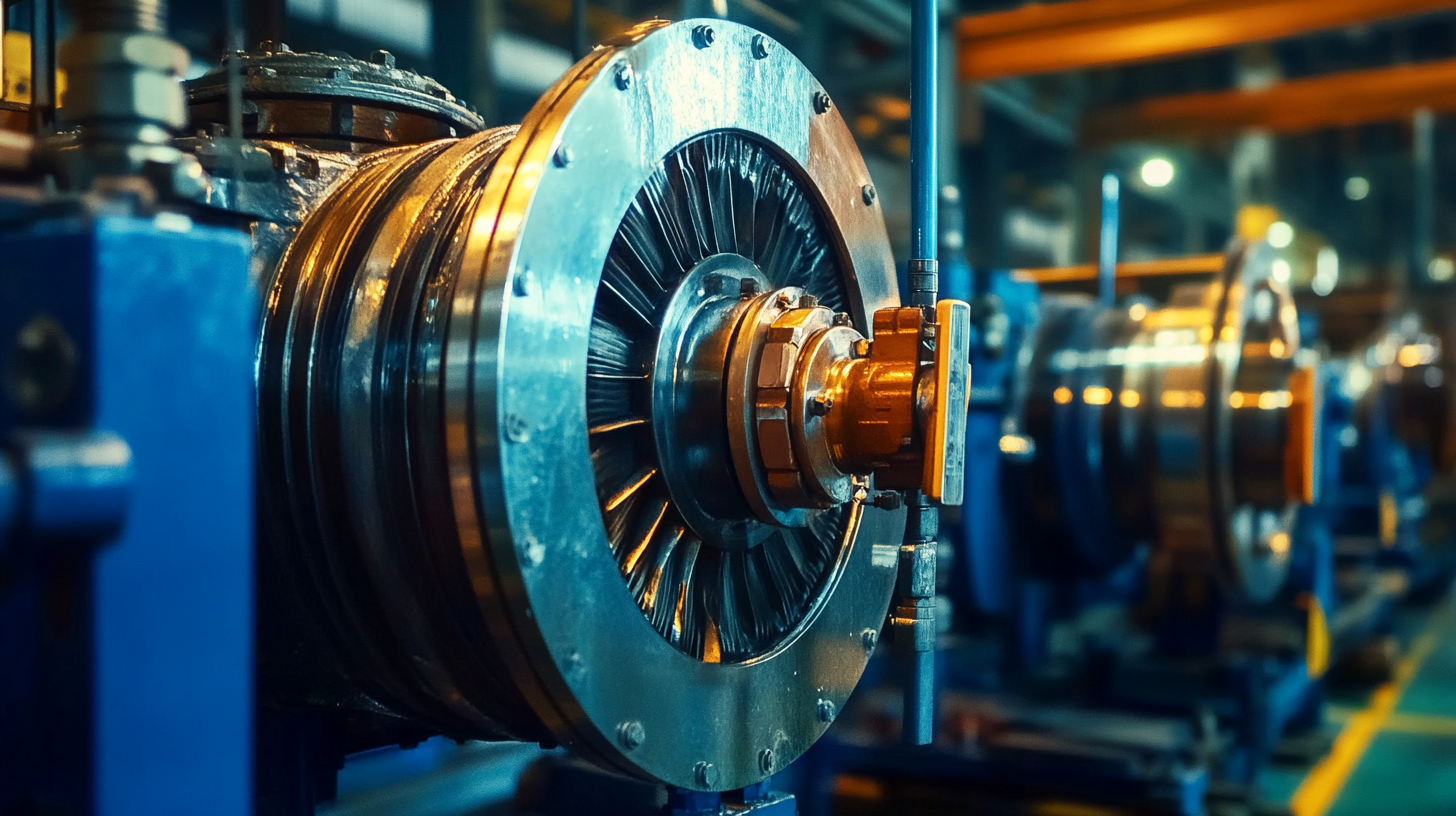

Three phase AC motors play a pivotal role in various industrial applications, providing the reliability and efficiency that modern industries demand. Unlike single phase motors, three phase motors deliver a constant torque which leads to smoother operation and reduced vibrations. This efficiency not only enhances the performance of machinery but also prolongs their lifespan, making them a cost-effective choice for manufacturers looking to optimize their production processes.

When selecting a three phase AC motor, consider the load requirements of your application. **Tip:** Always match the motor size and power to your specific needs to avoid energy wastage. Additionally, ensuring that your motor is compatible with existing systems is crucial for seamless integration. **Tip:** Conduct a thorough analysis of your operational environment to choose motors that can withstand factors like temperature fluctuations and moisture levels.

Moreover, maintenance plays a vital role in the longevity of three phase AC motors. Regular inspections and timely servicing can prevent unexpected downtime. **Tip:** Implement a predictive maintenance schedule that utilizes monitoring tools to keep track of motor performance, thereby minimizing potential issues before they escalate. Embracing these practices will not only optimize your operations but also ensure that your industrial processes run smoothly and efficiently.

5 Reasons Why the Best Three Phase AC Motor is Essential for Your Industry Needs

Key Advantages of Using the Best Three Phase AC Motor for Efficiency

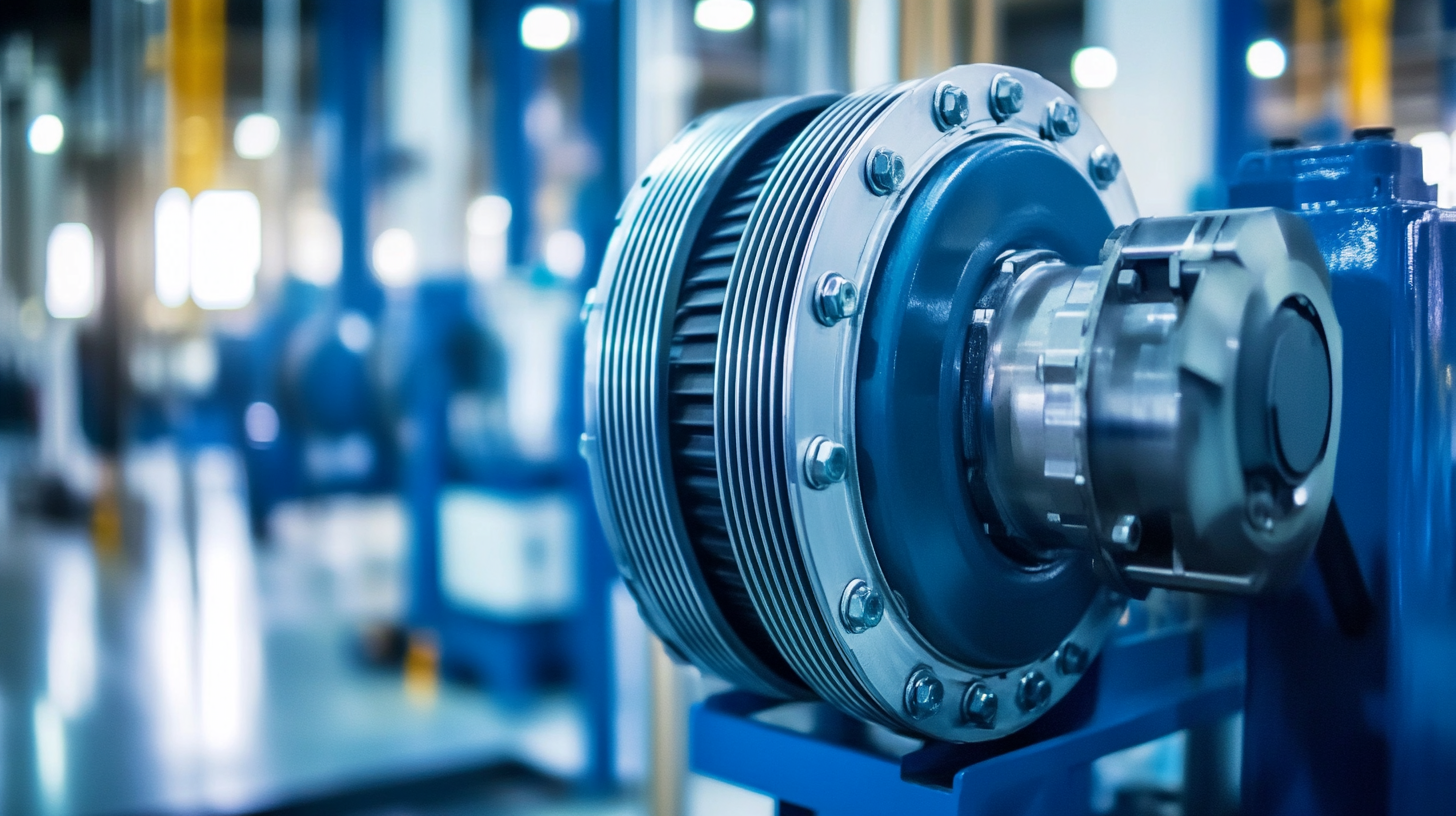

Investing in the best three-phase AC motor can significantly enhance operational efficiency in various industries. According to a report by the International Energy Agency, electric motors account for nearly 65% of the global industrial electricity consumption. The efficiency of three-phase AC motors typically ranges between 85% to 95%, which means they can reduce energy costs while minimizing heat generation. This efficiency translates directly to cost savings and a smaller carbon footprint, making them essential for environmentally-conscious operations.

Furthermore, three-phase AC motors provide superior performance stability, especially in heavy-duty applications. A study published by the U.S. Department of Energy indicates that these motors deliver higher starting torque and smooth operation, which is crucial for industries such as manufacturing and oil extraction, where heavy loads are common. The robust design of three-phase motors not only extends their lifespan but also reduces maintenance costs, as they generally require fewer repairs compared to single-phase alternatives. These key advantages make the best three-phase AC motors an indispensable component for optimizing productivity and sustainability in industrial settings.

5 Reasons Why the Best Three Phase AC Motor is Essential for Your Industry Needs - Key Advantages of Using the Best Three Phase AC Motor for Efficiency

| Advantage | Description | Efficiency (%) | Typical Applications |

|---|---|---|---|

| Higher Efficiency | Three phase motors provide better efficiency and consume less power. | 90 - 95 | Pumps, fans, conveyors |

| Smooth Operation | They offer smoother torque delivery, resulting in reduced vibration and noise. | N/A | Industrial machinery, compressors |

| Durability | Designed for long life, capable of handling heavy workloads without overheating. | N/A | Heavy machinery, agricultural equipment |

| Cost-Effective | Higher initial investment but lower operational costs due to efficiency. | N/A | Manufacturing, assembly lines |

| Versatile Use | Can be used in a wide range of industrial applications from small to large scale. | N/A | Textile machinery, HVAC systems |

Common Problems Associated with Inferior AC Motors in Industry

When it comes to industrial applications, the choice of AC motors plays a critical role in overall operational efficiency. Inferior three-phase AC motors often lead to a myriad of problems that can significantly impact productivity. One common issue is overheating, which can arise from poor insulation and substandard materials. This not only reduces the lifespan of the motor but also increases the risk of equipment failure, causing costly downtimes.

Another prevalent problem with low-quality AC motors is inefficiency. Many inferior models suffer from poor power factor and excessive energy consumption, which translates into higher operational costs. This inefficiency not only affects the bottom line but can also lead to increased strain on electrical systems, potentially causing further complications in plant operations. Moreover, these motors might exhibit inconsistent performance, leading to fluctuations in output and compromised product quality, highlighting the importance of investing in reliable three-phase AC motors suited to industrial requirements.

How to Select the Right Three Phase AC Motor for Your Business Needs

When selecting the right three-phase AC motor for your business needs, understanding the market dynamics is crucial. The medium-voltage drive market has been witnessing significant growth, fueled by a rising demand across various industries such as manufacturing, oil and gas, and water treatment. These motors are essential for powering equipment like pumps, conveyors, and compressors, emphasizing the importance of selecting a motor that not only meets power needs but also aligns with specific application requirements.

Consideration of power range is vital; motors are categorized into several segments such as <1MW, 1MW to 3MW, 3MW to 7MW, and >7MW. Each category serves distinct operational capabilities and efficiency levels. Analyzing your business's particular operational demands and environmental factors will guide you in making informed decisions. Furthermore, understanding the influence of global economic trends, such as shifts in major markets, can impact your motor selection process, ensuring that you invest in equipment that will provide long-term reliability and performance.

Maintenance Tips to Prevent Issues with Your Three Phase AC Motor

Proper maintenance of three-phase AC motors is crucial for ensuring optimal performance and longevity. According to a report from the Electric Power Research Institute, unexpected motor failures can lead to costly downtimes, averaging around $260,000 per incident for larger facilities. Regular preventive maintenance can mitigate these risks. Key maintenance practices include performing routine inspections, checking for signs of wear, and ensuring proper lubrication of bearings.

In addition to scheduled inspections, leveraging predictive maintenance technology can further enhance reliability. A study published in the Journal of Manufacturing Science and Engineering highlights that implementing vibration analysis and thermal imaging can detect issues before they escalate. These techniques have been shown to decrease unplanned downtime by up to 30%, saving companies significant resources and enhancing productivity. By adopting a proactive approach to maintenance, industries can ensure that their three-phase AC motors operate efficiently, contributing to overall operational excellence.

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top