2026 Best Aluminum Motor Options for Your Needs?

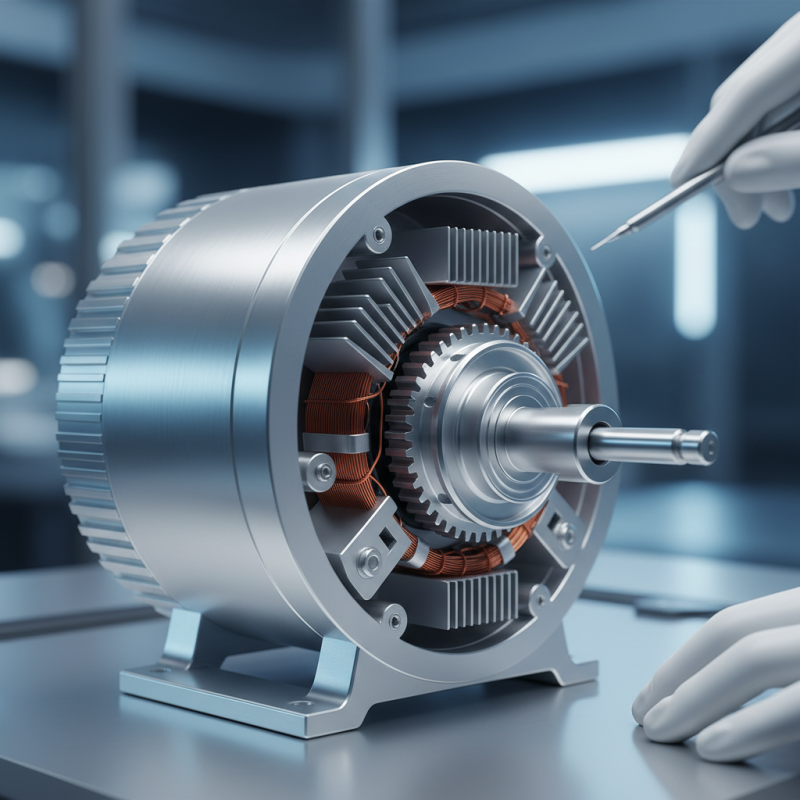

The aluminum motor industry has seen remarkable advancements in technology and efficiency. According to Dr. Emily Carter, a leading expert in the field, "Aluminum motors stand out for their lightweight and durability." Her insight highlights the key benefits of aluminum motors for various applications.

One of the most significant advantages of aluminum motors is their weight. This makes them ideal for industries where reducing weight is crucial. Electric vehicles, for example, benefit greatly from aluminum motors, enhancing performance and range. However, it's important to consider specific needs. Not every option will suit every application.

Furthermore, while aluminum motors are innovative, they also present challenges. Some buyers may overlook crucial factors like heat dissipation or cost. As the industry evolves, it’s essential for consumers to deeply reflect on their choices. The right aluminum motor could make a substantial difference in functionality and efficiency.

Overview of Aluminum Motors and Their Benefits

Aluminum motors are increasingly popular due to their numerous benefits. They are lightweight yet durable. This makes them ideal for various applications, from industrial uses to electric vehicles. Their lower weight allows for improved energy efficiency, which is crucial in today's eco-conscious world. These motors offer better performance due to their ability to operate at higher speeds without overheating.

Another key advantage is their corrosion resistance. Aluminum does not rust, unlike iron or steel. This property enhances the motor's lifespan, especially in harsh environments. Maintenance becomes less of a hassle. However, it's important to note that proper insulation is necessary to prevent potential issues with electrical conduction. As with any material, there are limitations.

While aluminum motors have many merits, they can be more expensive than traditional options. This higher upfront cost may not always justify the benefits for some applications. Understanding your specific needs is vital. Balancing weight, performance, and cost can be challenging. Buyers should reflect on these factors carefully to make informed decisions.

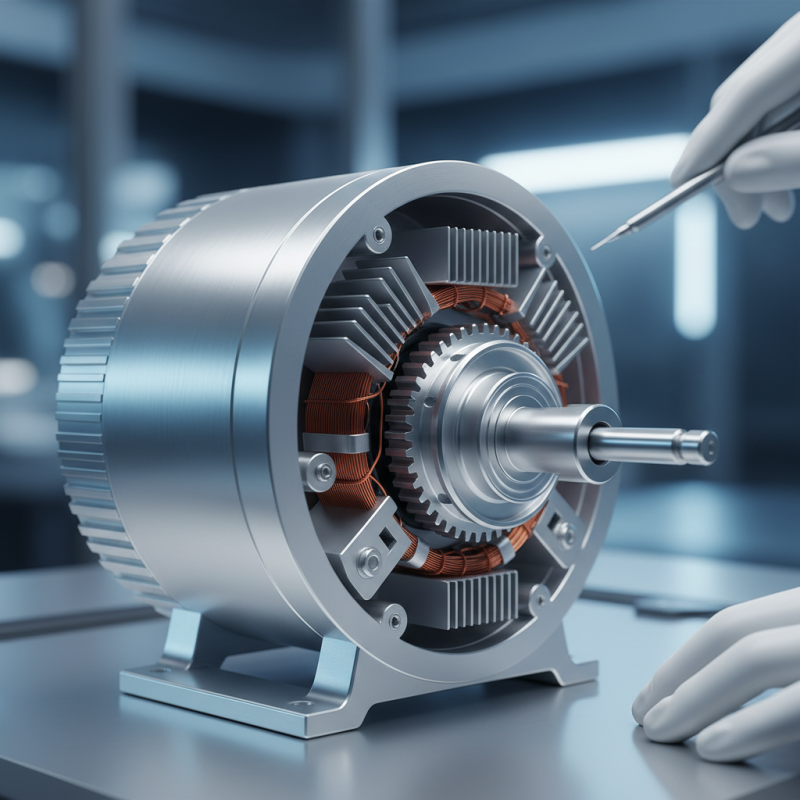

Key Factors to Consider When Choosing Aluminum Motors

When selecting aluminum motors, several key factors must be evaluated. The power-to-weight ratio stands out as crucial. Motors with an ideal balance enhance performance without adding excessive weight. Reports indicate that aluminum motors can be up to 50% lighter than traditional options, which allows for improved efficiency.

Durability is another vital consideration. Aluminum exhibits excellent resistance to corrosion, extending the motor's lifespan. However, not all aluminum materials offer the same resilience. The right alloy can significantly affect longevity. Industry data suggests that over 30% of motor failures stem from material quality. Choosing between different grades is essential for longevity.

Finally, thermal management plays a significant role. Aluminum dissipates heat more efficiently than many materials. However, for high-performance applications, additional cooling measures might be necessary. This is an area often overlooked, leading to potential overheating issues. Many experts emphasize testing under real conditions to avoid surprises.

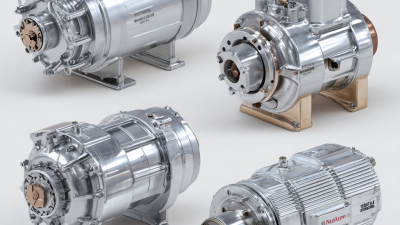

Top Aluminum Motor Manufacturers and Their Offerings

When exploring aluminum motor options, it's crucial to understand the major manufacturers in this space. The industry is experiencing a shift, with a growing preference for lightweight materials. Aluminum motors offer excellent performance while minimizing weight. According to a recent industry report, aluminum motor sales have increased by 25% over the past year, highlighting their rising popularity.

Top manufacturers are focusing on innovations in efficiency and durability. Recent data indicates that aluminum motors can achieve efficiency rates of up to 92%. This is significant when considering energy saving and operational costs. However, not all products meet these standards. Quality can vary widely, and some motors may not perform as advertised. Buyers should conduct thorough research and consider real-world applications.

Many manufacturers also offer customizable options. This allows buyers to choose specific features that best suit their needs. Yet, customization can come with increased costs and longer lead times. This is something buyers need to weigh against their operational priorities. The market is competitive, but maintaining quality remains a challenge for many producers.

Comparison of Performance in Aluminum vs. Other Motor Types

When considering motors, aluminum options present distinct advantages over conventional materials. Aluminum is lightweight, which significantly enhances performance. This ensures increased efficiency in applications needing mobility. The corrosion resistance of aluminum also plays a key role. Motors exposed to harsh conditions can benefit greatly.

However, aluminum motors may face challenges, especially in high-temperature environments. While they conduct heat efficiently, overheating can lead to failures. This raises questions about durability compared to steel or other robust materials. In applications requiring high strength, aluminum may fall short.

In overall performance, aluminum motors shine in speed and efficiency. They are ideal for various applications, from household uses to industrial tasks. Those looking for balance should weigh aluminum's strengths against its weaknesses. It's crucial to evaluate your specific needs before making a choice.

Applications of Aluminum Motors in Various Industries

Aluminum motors are increasingly popular across various industries due to their lightweight construction and efficiency. In the automotive sector, these motors contribute to the overall energy efficiency of vehicles. They help reduce weight, which can enhance fuel economy and performance. Electric vehicles, in particular, benefit from the lightweight design of aluminum motors, allowing for improved battery life and range.

In industrial applications, aluminum motors have shown promising results. They are often used in manufacturing equipment and conveyor systems. The corrosion resistance of aluminum makes these motors ideal for harsh environments. However, their heat dissipation can be a challenge. Proper cooling methods must be employed to avoid overheating issues.

The aerospace industry also utilizes aluminum motors. Lightweight components are crucial for flight efficiency. These motors provide power for various functions, from navigation systems to control surfaces. But there's room for improvement. Engineers are still exploring better materials to enhance performance. Innovations in motor design could further revolutionize how industries use aluminum motors.

2026 Best Aluminum Motor Options for Your Needs

| Motor Type |

Power Output (kW) |

Efficiency (%) |

Weight (kg) |

Application |

| Brushless AC Motor |

5 |

90 |

15 |

Robotics |

| Induction Motor |

10 |

85 |

20 |

Manufacturing |

| Synchronous Motor |

15 |

92 |

25 |

HVAC Systems |

| Stepper Motor |

3 |

80 |

5 |

3D Printing |

| DC Motor |

1 |

78 |

3 |

Electric Vehicles |