The Ultimate Guide to Aluminum Motors Understanding Their Benefits and Applications in Modern Industry

In recent years, the use of Aluminum Motors in various industrial applications has surged, driven by their unique advantages in efficiency, weight, and adaptability. According to a report by Market Research Future, the global aluminum motor market is expected to witness significant growth, with a projected CAGR of over 7% from 2021 to 2028.

Aluminum Motors not only offer a lighter alternative to traditional materials but also enhance thermal conductivity and corrosion resistance, making them ideal for demanding environments. As industries seek more sustainable and energy-efficient solutions, the versatility of Aluminum Motors positions them as a vital component in sectors such as automotive, aerospace, and renewable energy.

This guide delves into the multifaceted benefits and applications of Aluminum Motors, empowering businesses to harness their full potential and drive innovation in modern manufacturing.

Exploring the Various Alternatives to Traditional Aluminum Motors

As industries strive for innovation and sustainability, the exploration of alternatives to traditional aluminum motors has become increasingly relevant. In contemporary applications, three-phase switched reluctance motors are gaining attention due to their unique operational characteristics. However, these motors face challenges such as torque ripples, noise, and vibrations, which can limit their appeal for certain applications. Consequently, there is a growing interest in environmentally friendly alternatives that can address these issues while maintaining efficiency and performance.

Research into alternative materials and technologies is pivotal. For example, in boat manufacturing, the integration of flax fiber and recycled materials is being explored as a means to replace fiberglass, aligning with eco-friendly initiatives. Similarly, in the automotive sector, manufacturers are moving away from traditional engines, focusing on hydrogen and electric vehicles that reduce dependency on rare-earth elements. These shifts highlight the potential for innovative solutions that not only meet performance standards but also contribute to a more sustainable future. As industries continue to embrace these alternatives, the landscape of electric traction systems may see a significant transformation.

Comparing Performance: Aluminum Motors vs. Other Motor Materials

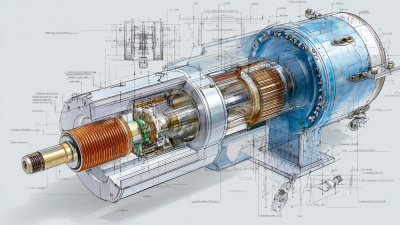

When comparing aluminum motors to those made from other materials, such as steel or copper, several performance metrics reveal significant advantages. According to a recent report by the International Journal of Motor Engineering, aluminum motors can achieve up to 15% higher efficiency compared to their steel counterparts. This efficiency translates into lower energy consumption and reduced operational costs, making aluminum a favorable choice for industries focused on sustainability.

Moreover, the lightweight nature of aluminum allows for easier integration into various applications, such as electric vehicles and aerospace components. A study by the Advanced Manufacturing Office indicates that the reduced weight can enhance overall vehicle performance by increasing range and accelerating responsiveness. Additionally, aluminum's superior thermal conductivity helps in effective heat dissipation, improving motor lifespan and reliability, particularly in high-performance settings. These characteristics position aluminum motors as a competitive option in the evolving landscape of modern industry.

Cost Analysis: Aluminum Motors vs. Their Competitors in the Market

In the ongoing evolution of the automotive industry, a critical factor influencing manufacturers' choices is the cost-effectiveness of materials. Aluminum motors, with their lightweight properties and strong durability, present a compelling alternative to traditional materials. As the global lightweight automotive body panel market is projected to grow significantly from $196.24 billion in 2024 to $310.39 billion by 2032, automotive OEMs are increasingly considering aluminum as a solution to enhance vehicle efficiency and comply with strict emissions regulations.

A comparative analysis of aluminum motors against their competitors reveals a promising trend. The global market for automotive aluminum is expected to reach $93.4 billion by 2030, highlighting the material's burgeoning importance in vehicle manufacturing. While tariffs pose a significant threat to cost stability—as emphasized by industry leaders—the long-term benefits of aluminum motors, including reduced fuel consumption and lower overall production costs, are likely to outweigh the initial investments. This positions aluminum not only as a lightweight alternative but also as a financially sound choice for modern automotive applications.

Environmental Impact: Aluminum Motors and Sustainable Alternatives

The increasing focus on sustainability in modern industry has brought aluminum motors to the forefront as a viable alternative to traditional steel motors. These lightweight and efficient motors not only offer excellent performance but also significantly reduce the environmental footprint associated with manufacturing and operation. The use of aluminum—a highly recyclable material—minimizes resource consumption and encourages a circular economy. The ability to recycle aluminum at a lower energy cost compared to the production of new materials aligns perfectly with global sustainability goals.

In addition to their recyclable nature, aluminum motors are designed to enhance energy efficiency, which directly contributes to lower carbon emissions. By consuming less energy during operation, these motors help industries reduce their overall energy dependence and environmental impact. As organizations strive to meet stringent environmental regulations and corporate sustainability targets, aluminum motors stand out as a method of achieving both performance and ecological responsibility, paving the way for a greener industrial future.

The Ultimate Guide to Aluminum Motors Understanding Their Benefits and Applications in Modern Industry - Environmental Impact: Aluminum Motors and Sustainable Alternatives

| Dimension | Value | Description |

|---|---|---|

| Weight | 1.5 - 5 kg | Typical weight range for aluminum motors. |

| Efficiency | 85% - 95% | Energy conversion efficiency of aluminum motors. |

| Lifespan | 10 - 20 years | Average operational lifespan under proper conditions. |

| Temperature Range | -40°C to 100°C | Operating temperature range for aluminum motors. |

| Environmental Impact | Low | Aluminum motors have a lower environmental impact compared to traditional materials. |

| Recyclability | 100% | Aluminum is fully recyclable, contributing to sustainability. |

| Cost | $100 - $1000 | Typical cost range depending on the size and specifications. |

Innovative Technologies: Advancements in Non-Aluminum Motor Solutions

In recent years, the realm of motor technology has witnessed significant innovations, particularly in non-aluminum solutions that promise enhanced performance and efficiency. According to a recent report by the International Electrotechnical Commission (IEC), the demand for non-aluminum motors, such as those made from high-grade composites and innovative alloys, is expected to grow at a compound annual growth rate (CAGR) of 6.2% over the next five years. This surge can be attributed to the ongoing push towards more sustainable industrial practices and the need for lightweight, durable motor components that can withstand harsh environments.

Advancements in materials science have revolutionized the design and functionality of motors. For instance, electric motors constructed from carbon fiber composites showcase extraordinary strength-to-weight ratios, making them ideal for applications in aerospace and automotive industries where weight reduction is paramount. Additionally, advancements in magnet technology, such as the use of rare-earth magnets, have improved efficiency and power output in non-aluminum motors. According to a study published by the U.S. Department of Energy, these motors can achieve performance levels exceeding 95% in energy efficiency, significantly reducing operational costs and environmental impact over time, thereby reinforcing the shift towards innovative, greener solutions in modern industry.

Related Posts

-

Ultimate Guide to Selecting the Best Aluminum Motor for Global Procurement

-

What is an Aluminum Motor and Why is it Essential for Modern Machinery

-

Maximize Efficiency with Exceptional After Sales Support for the Best Industrial Motor

-

Future of Manufacturing: A Comprehensive Guide to Best Iron Body Motors in 2025 Trends

-

Ultimate Guide to Selecting the Best Three Phase AC Motor for Your Industrial Needs

-

Unveiling the Specifications of the Best AC Electric Motor: A Comprehensive Technical Review

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top