What is an Aluminum Motor and Why is it Essential for Modern Machinery

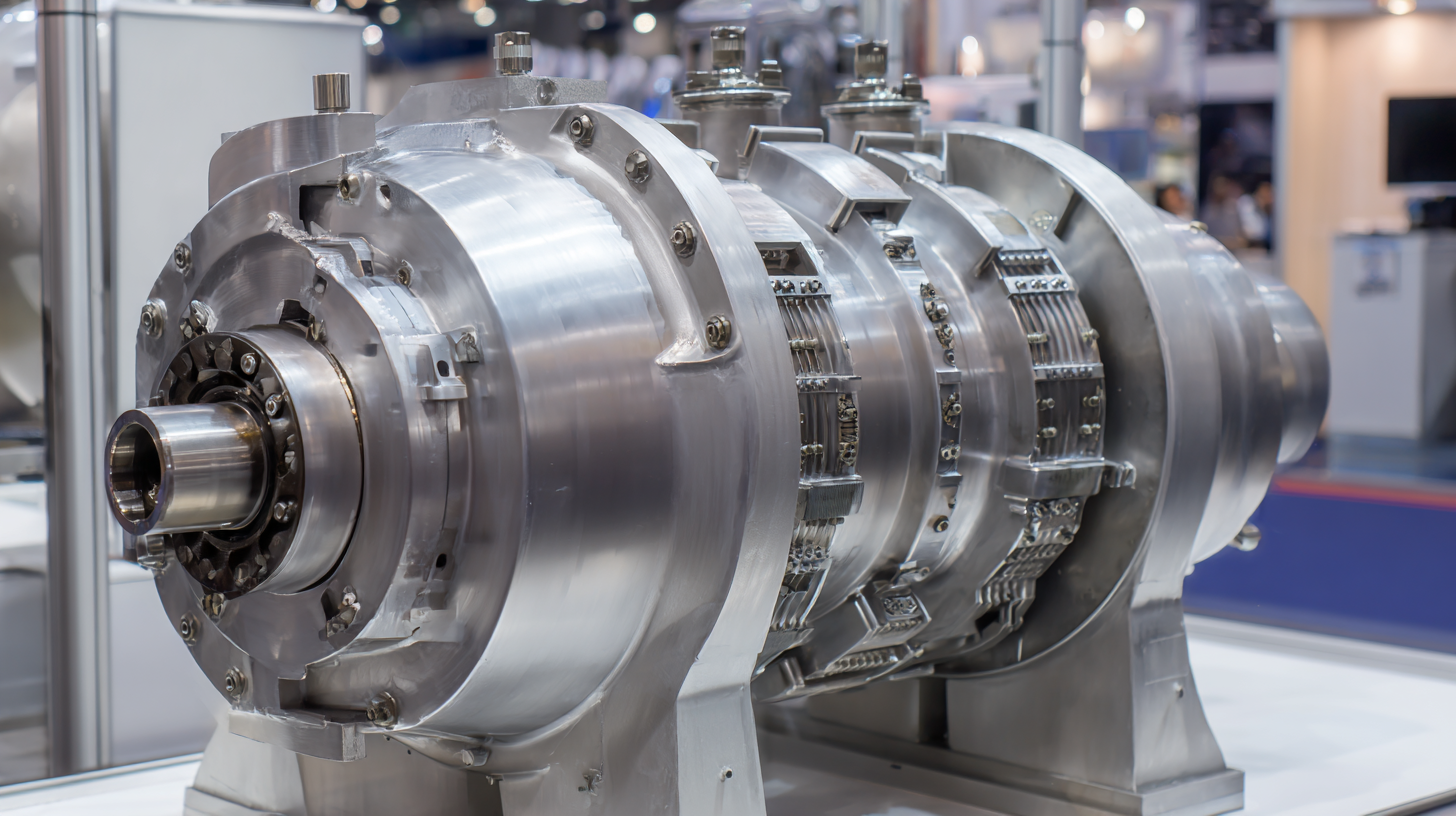

The rise of the Aluminum Motor has become a pivotal aspect of modern machinery, making significant strides in both efficiency and performance. According to the International Electrotechnical Commission, the global market for electric motors, which prominently includes aluminum variants, is projected to reach $152 billion by 2023, driven by advancements in automation and sustainability. This lightweight yet robust motor technology not only enhances energy efficiency but also contributes to reducing the carbon footprint of industrial operations. Industries are increasingly recognizing the importance of integrating aluminum motors into their systems to leverage benefits such as superior heat dissipation and corrosion resistance. As we delve deeper into the significance of Aluminum Motors, it's essential to explore their advantages, applications, and the critical role they play in revolutionizing the machinery landscape.

The Role of Aluminum Motors in Enhancing Machinery Efficiency

Aluminum motors have increasingly become essential components in modern machinery due to their ability to enhance operational efficiency. According to a report from the International Energy Agency, electric motors account for approximately 45% of global energy consumption in the industrial sector. By utilizing lightweight aluminum in motor construction, manufacturers can significantly reduce energy losses associated with heavier materials, leading to improved overall performance. Research indicates that aluminum motors can achieve up to 20% better efficiency compared to their iron counterparts, a crucial advantage in industries striving for sustainability.

Aluminum motors have increasingly become essential components in modern machinery due to their ability to enhance operational efficiency. According to a report from the International Energy Agency, electric motors account for approximately 45% of global energy consumption in the industrial sector. By utilizing lightweight aluminum in motor construction, manufacturers can significantly reduce energy losses associated with heavier materials, leading to improved overall performance. Research indicates that aluminum motors can achieve up to 20% better efficiency compared to their iron counterparts, a crucial advantage in industries striving for sustainability.

Moreover, the thermal properties of aluminum contribute to increased durability and reduced heat generation during operation. The U.S. Department of Energy has highlighted that optimized cooling in aluminum motors can lead to an extended lifespan of the equipment, minimizing downtime and maintenance costs. Additionally, the lower weight of aluminum motors allows for easier integration into various machinery designs, facilitating innovation and flexibility in manufacturing processes. This combination of efficiency, durability, and versatility positions aluminum motors as a critical technology driving advancements in modern machinery.

Key Advantages of Aluminum Motors Over Traditional Materials

Aluminum motors are becoming increasingly essential in modern machinery due to their remarkable advantages over traditional materials like steel and copper. One of the standout benefits is their lightweight nature, which translates to improved energy efficiency and better performance. The reduced weight allows for easier handling and installation, particularly in applications where space and weight constraints are crucial.

Aluminum motors are becoming increasingly essential in modern machinery due to their remarkable advantages over traditional materials like steel and copper. One of the standout benefits is their lightweight nature, which translates to improved energy efficiency and better performance. The reduced weight allows for easier handling and installation, particularly in applications where space and weight constraints are crucial.

Another key advantage of aluminum motors is their excellent thermal conductivity. This property facilitates more efficient heat dissipation, allowing motors to operate at lower temperatures and extend their lifespan. For industries looking to enhance their operational reliability, this is a significant benefit. Regular maintenance can further enhance performance; ensure that the motors are kept clean and free from dust and debris, which can impede airflow and cooling efficiency.

Additionally, corrosion resistance is another factor where aluminum motors excel. They are less prone to rust and other forms of degradation compared to traditional materials, making them ideal for harsh environments. To maximize the benefits, consider utilizing protective coatings that can further enhance their longevity, especially in outdoor applications or damp conditions. These features not only improve durability but also reduce long-term maintenance costs for businesses.

Applications of Aluminum Motors in Various Industries

Aluminum motors have become integral to a wide array of industries, thanks to their lightweight construction and excellent efficiency. In manufacturing and assembly lines, these motors provide the power necessary to drive automated machinery, enabling faster production cycles and reducing energy consumption. Their ability to operate quietly makes them an ideal choice for environments where noise reduction is essential, such as food processing and pharmaceuticals. Additionally, with their resistance to corrosion, aluminum motors can thrive in challenging conditions, extending their lifespan and reliability.

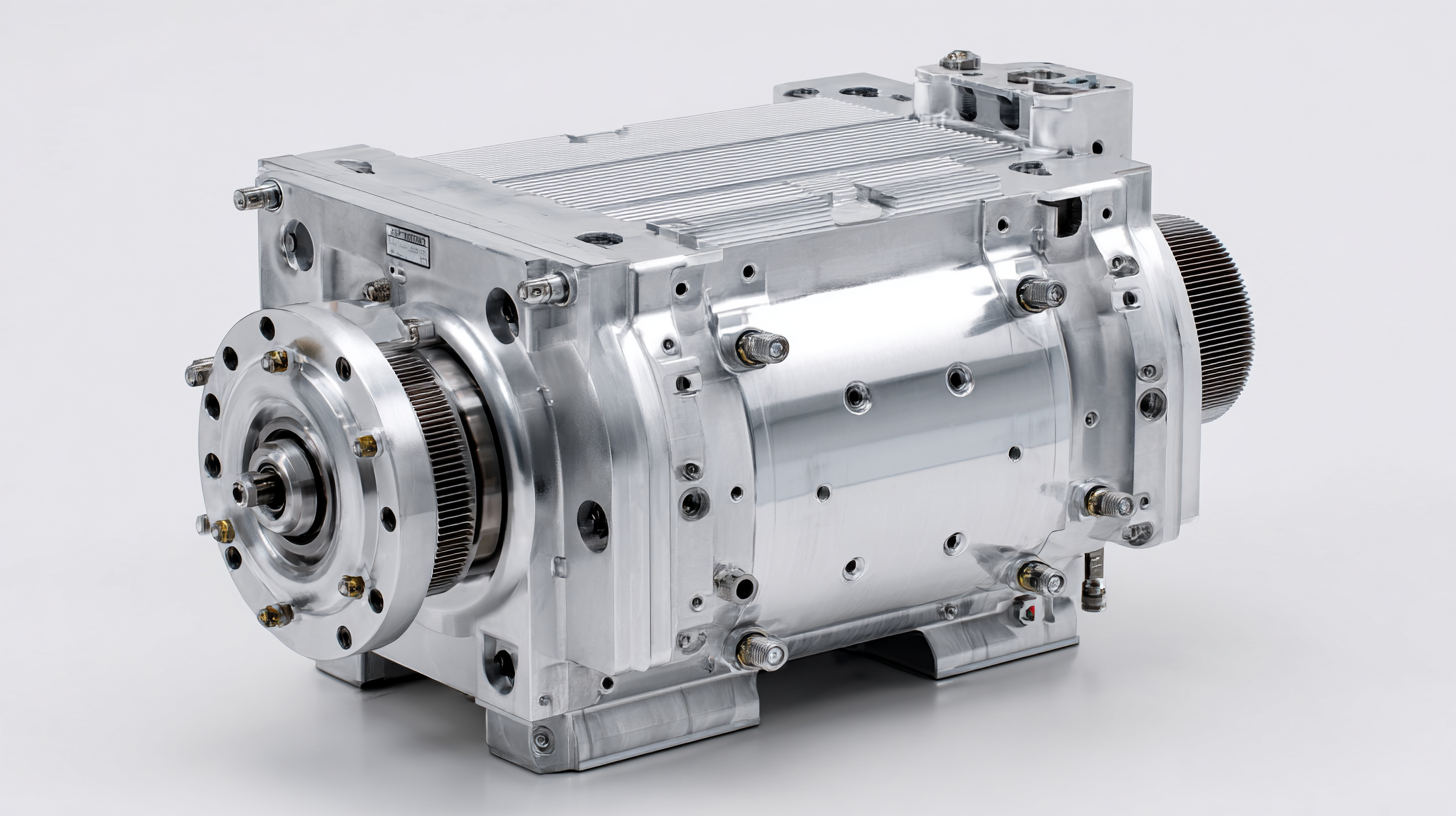

In the automotive industry, aluminum motors are increasingly favored for electric vehicles (EVs) due to their lightweight properties, which help enhance overall vehicle performance and efficiency. Their use in material handling machinery, such as forklifts and conveyor systems, is also growing, as these motors facilitate smoother operation while minimizing energy costs. Furthermore, in the renewable energy sector, aluminum motors are vital components in wind and solar technologies, driving the push for sustainable and eco-friendly power solutions. As industries continue to innovate, the versatility of aluminum motors makes them an essential asset for modern machinery.

Innovative Designs: The Future of Aluminum Motors in Machinery

Aluminum motors are becoming pivotal in the evolving landscape of modern machinery. As innovative designs emerge, these lightweight yet robust components are enhancing efficiency across various applications. The appeal of aluminum in motor construction lies in its superior thermal conductivity and resistance to corrosion, factors that lead to

improved performance and longevity in demanding environments. This shift towards aluminum motors not only supports sustainability efforts by reducing energy consumption but also meets the increasing demands for higher power density in electrical machines.

Incorporating aluminum motors into machinery designs offers manufacturers a strategic advantage. They can help reduce overall weight, which is particularly beneficial in automotive and aerospace sectors where every gram counts. As companies push for innovative designs, here are a few tips: focus on optimizing the motor's cooling systems to maximize performance, and consider integrating smart technology to monitor thermal and mechanical stresses in real-time, ensuring the longevity and reliability of the motor in diverse conditions. Embracing these strategies will pave the way for more efficient and sustainable industrial practices moving forward.

Environmental Benefits of Using Aluminum Motors in Manufacturing

Aluminum motors are becoming increasingly vital in modern machinery, particularly due to their environmental benefits in manufacturing processes. One of the most significant advantages of aluminum is its lightweight nature. These motors reduce energy consumption, leading to lower carbon emissions during production and operation. By minimizing the weight of machines, manufacturers can enhance efficiency, translating into less energy required for operation. This reduction not only benefits the environment but also contributes to cost savings for companies that prioritize sustainability.

Moreover, aluminum is highly recyclable, making it an eco-friendly choice in manufacturing. Unlike other materials that may end up in landfills, aluminum can be recycled indefinitely with minimal loss of quality. This aspect is critical for manufacturers looking to adopt circular economy principles. The use of aluminum motors aligns with global sustainability goals, allowing companies to reduce their ecological footprint while still meeting production demands. As industries continue to seek greener alternatives, aluminum motors stand out as a smart, responsible investment that supports both operational efficiency and environmental preservation.

What is an Aluminum Motor and Why is it Essential for Modern Machinery

| Dimension | Aluminum Motor | Other Materials |

|---|---|---|

| Weight (kg) | 8.5 | 12.0 |

| Efficiency (%) | 90 | 85 |

| Cost (USD) | 150 | 200 |

| Lifespan (years) | 15 | 10 |

| Recyclability (%) | 100 | 70 |

| Operating Temperature (°C) | -40 to 120 | -20 to 100 |

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top